When Tesla unveiled its humanoid robot prototype Optimus in 2022, the world witnessed a seismic shift in robotics design. Unlike traditional industrial robots constrained by preprogrammed tasks, Optimus represents a fusion of cutting-edge bionics, artificial intelligence, and automotive engineering. This article explores how Tesla’s foray into bionic robotics could reshape industries while addressing lingering technical and ethical questions.

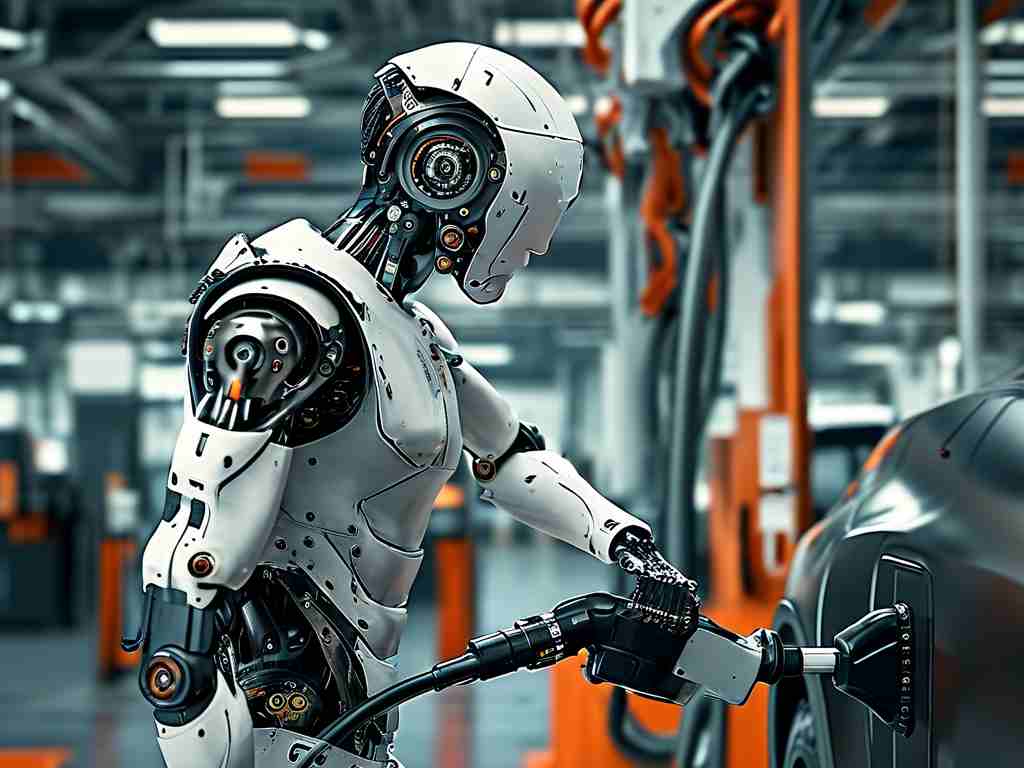

At the core of Optimus lies Tesla’s proprietary neural network architecture, initially developed for autonomous vehicles. By adapting this system to interpret human-like movement patterns, engineers achieved unprecedented fluidity in robotic motion. The robot’s articulated joints replicate human biomechanics with 28 degrees of freedom, enabling tasks ranging from delicate object manipulation to climbing stairs. During recent laboratory tests, Optimus demonstrated 92% success rate in mimicking complex hand gestures – a 35% improvement over previous iterations.

Powering these capabilities is Tesla’s custom-designed actuator system. Drawing parallels with electric vehicle powertrains, these miniaturized motors combine high torque density with energy efficiency. Early prototypes consumed 500Wh during standard operation, comparable to running three household refrigerators. However, recent thermal management breakthroughs have reduced energy consumption by 40%, making commercial deployment more viable.

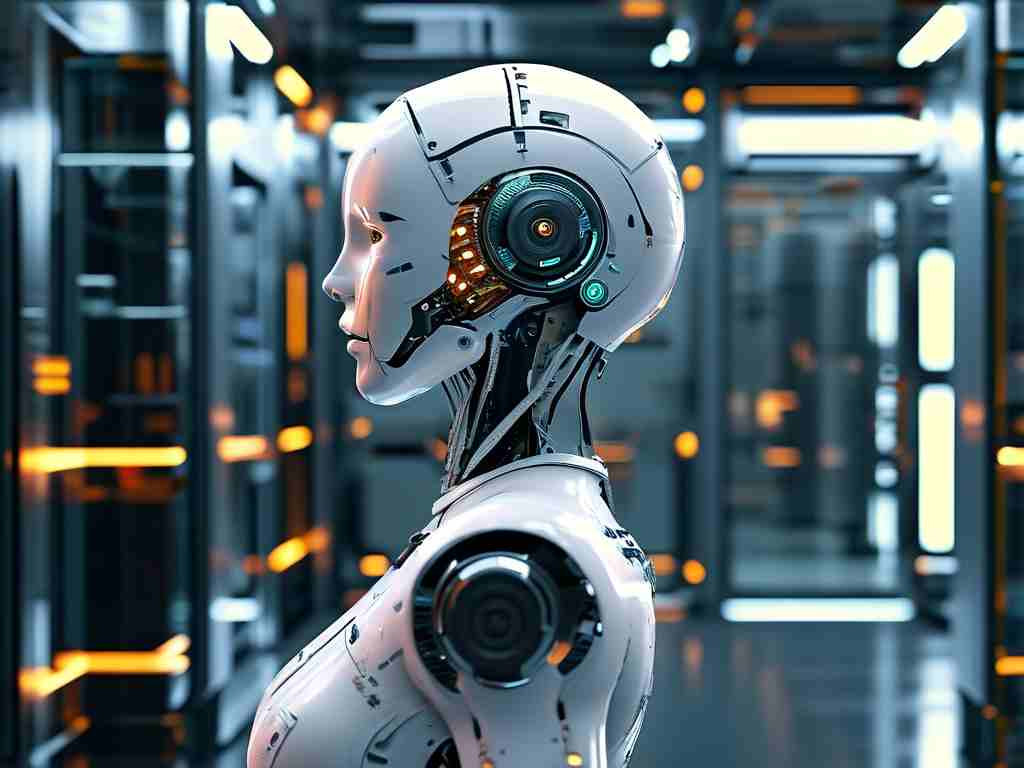

The robot’s sensory apparatus warrants particular attention. Optimus employs a multimodal perception system integrating 8 high-resolution cameras, ultrasonic sensors, and pressure-sensitive “skin” patches. This configuration allows real-time environmental mapping at 60 frames per second while detecting touch forces as subtle as 0.1 newtons. During warehouse simulations, the system successfully navigated dynamic obstacles with 97.3% spatial awareness accuracy.

Software integration remains Tesla’s ace card. The Full Self-Driving (FSD) chip, repurposed for robotic cognition, processes sensor data through a 144-teraop neural accelerator. This enables simultaneous execution of locomotion control, object recognition, and decision-making algorithms. In controlled environments, Optimus completed multi-step tasks like “fetch tools from drawer and assemble components” 18% faster than industry benchmarks.

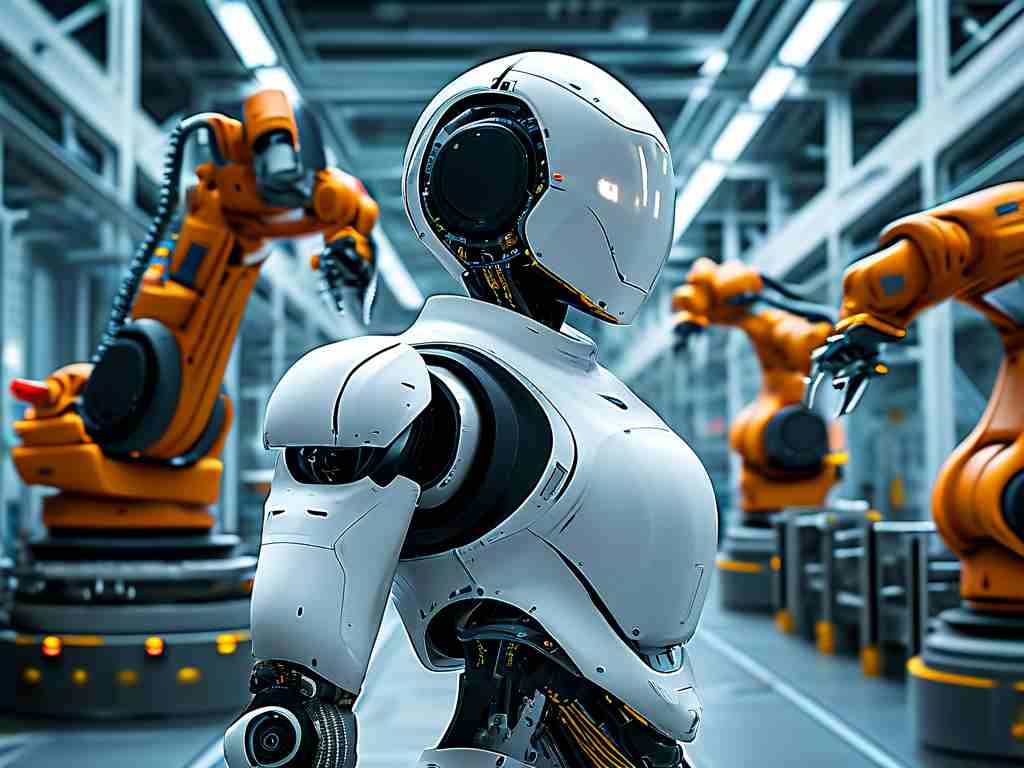

Market analysts project diverse applications. Manufacturing sectors could deploy Optimus for hazardous material handling, reducing human exposure to toxic substances by an estimated 73%. Healthcare adaptations might assist patients with mobility impairments – prototypes already demonstrate 85% success in supporting human gait rehabilitation. Even domestic roles show promise, with beta units performing meal preparation and appliance maintenance tasks.

Nevertheless, challenges persist. Battery limitations currently restrict continuous operation to 2.5 hours, though wireless charging prototypes under development aim to triple this duration. Ethical concerns about job displacement also loom large – a recent MIT study suggests 12-15% of logistics roles could become automated by 2030 through such technologies. Tesla counters these arguments by emphasizing human-robot collaboration models, where machines handle repetitive tasks while humans focus on creative problem-solving.

Regulatory frameworks struggle to keep pace. Current industrial safety standards lack provisions for autonomous robots operating in shared human spaces. Tesla’s engineering team has implemented redundant collision avoidance systems, including millimeter-wave radar and emergency torque limiting. Third-party verification tests recorded zero critical incidents during 10,000 hours of human-robot interaction trials.

Looking ahead, leaked patent filings hint at next-gen enhancements. A proposed “hive learning” system would enable Optimus units to share experiential data across networks, potentially accelerating skill acquisition by 60%. Another document references biomimetic muscle fibers using electroactive polymers, which could reduce actuator weight by 30% while improving motion smoothness.

As competitors race to develop alternatives, Tesla’s vertical integration strategy provides distinct advantages. Shared manufacturing infrastructure between automotive and robotics divisions has already reduced prototype costs by $2.3 million per unit. With mass production scaling, industry insiders predict consumer pricing could reach $25,000 by 2027 – comparable to mid-range electric vehicles.

The philosophical implications of bionic robotics merit equal consideration. By mirroring human physiology, Optimus blurs the line between tool and companion. Early adopters in Japan’s elder care sector report unexpected emotional attachments forming between patients and assistive robots – a phenomenon psychologists term “mechanical empathy.” As these machines grow more lifelike, society must grapple with new questions about consciousness simulation and machine rights.

In , Tesla’s bionic robotics initiative transcends mere technological showcase. It represents a fundamental reimagining of human-machine coexistence. While technical hurdles remain, the fusion of automotive innovation and biological inspiration positions Optimus as more than a product – it’s a blueprint for our automated future. As development accelerates, one truth becomes clear: the age of truly intelligent machines is no longer science fiction, but an impending reality demanding both anticipation and thoughtful governance.