In the rapidly evolving landscape of industrial automation, Doosan Robotics has emerged as a trailblazer, redefining how industries integrate robotic systems into their workflows. With a focus on precision, adaptability, and user-centric design, the company’s innovations are reshaping manufacturing, logistics, and even service sectors. This article explores the core technologies driving Doosan Robotics and their transformative impact on modern automation.

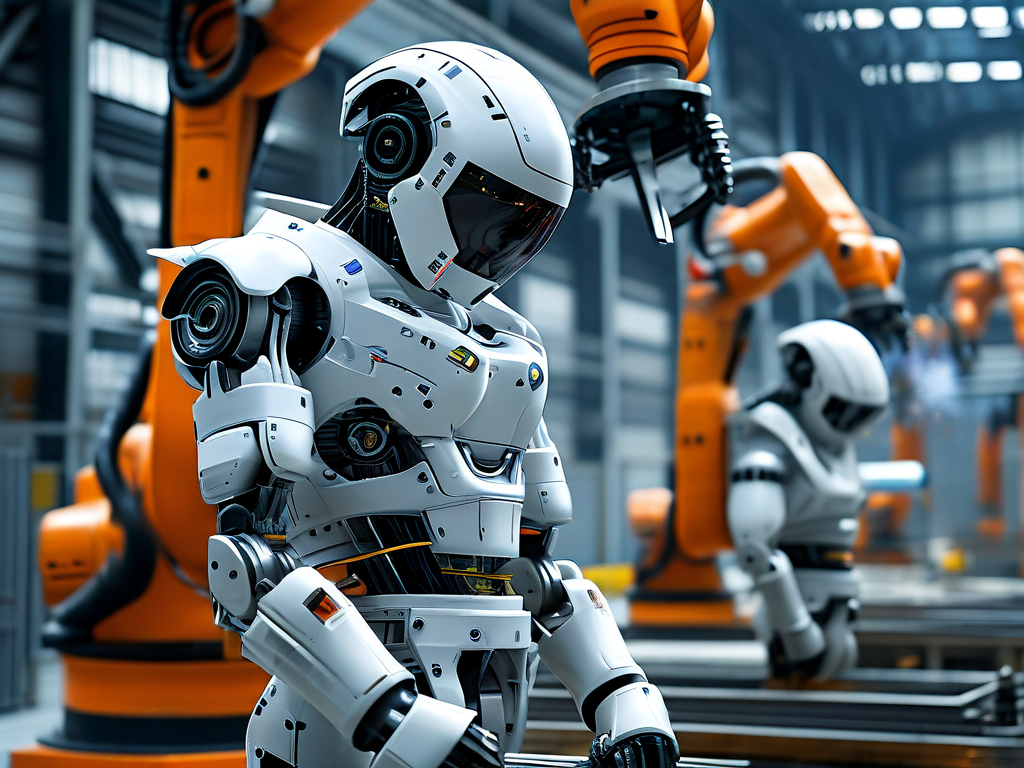

The Evolution of Collaborative Robotics

Doosan Robotics has carved a niche in collaborative robotics (cobots), a segment that emphasizes human-robot interaction. Unlike traditional industrial robots confined to safety cages, cobots from Doosan are designed to work alongside humans, enhancing productivity without compromising safety. Their A-Series robots, for instance, feature advanced force-sensing capabilities that allow immediate shutdown upon detecting unexpected contact. This technology not only minimizes workplace accidents but also enables seamless integration into dynamic environments like small-batch production lines or custom assembly processes.

One standout application is in the automotive industry, where Doosan’s cobots assist in precision tasks such as screw driving and component inspection. By reducing repetitive strain on human workers, these robots improve efficiency while maintaining high-quality outputs. Additionally, their lightweight design and easy programming interface have made them accessible to small and medium enterprises (SMEs), democratizing automation for businesses previously constrained by cost or technical expertise.

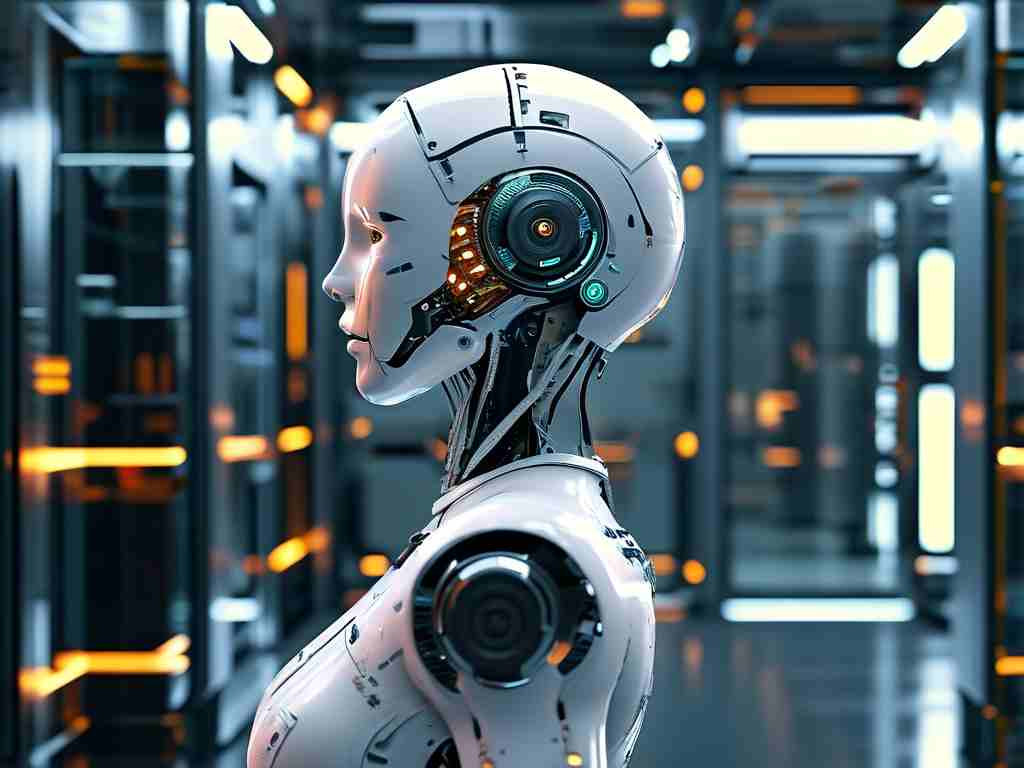

AI-Driven Vision Systems

A key differentiator for Doosan Robotics lies in its integration of artificial intelligence (AI) with vision systems. The company’s proprietary vision software, combined with 3D cameras, enables robots to perform complex tasks such as object recognition, sorting, and quality control. For example, in e-commerce warehouses, Doosan’s robots equipped with AI vision can rapidly identify and categorize items of varying shapes and sizes, streamlining order fulfillment processes.

This technology also plays a critical role in adaptive manufacturing. In one case study, a consumer electronics manufacturer utilized Doosan’s vision-enabled robots to inspect circuit boards. The system detected microscopic defects with 99.8% accuracy, far surpassing human capabilities. By leveraging machine learning algorithms, these robots continuously improve their detection rates, ensuring long-term value for enterprises.

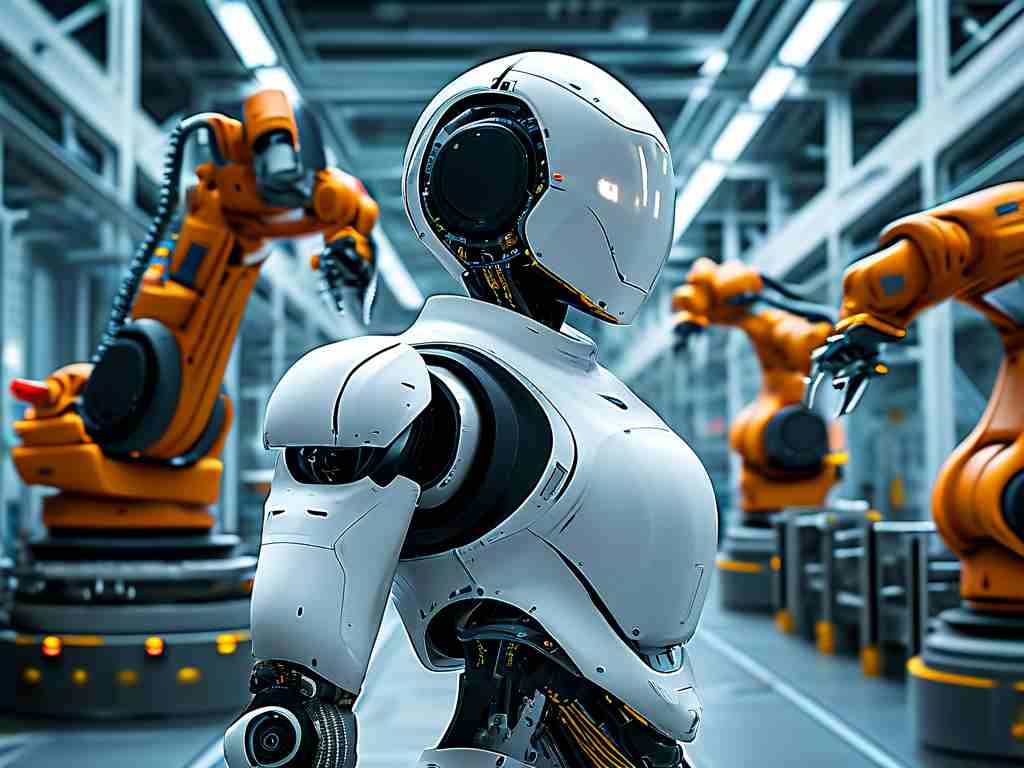

Modular Design and Scalability

Doosan’s emphasis on modularity allows its robotic systems to scale alongside business needs. The company’s M-Series modular robots, for instance, can be reconfigured for tasks ranging from welding to packaging simply by swapping end-effectors or adjusting software parameters. This flexibility is particularly valuable in industries with fluctuating demand, such as seasonal product manufacturing.

A notable example is a food processing plant that adopted Doosan’s modular robots for packaging and palletizing. During peak seasons, the facility expanded its robotic fleet by integrating additional units within days, avoiding prolonged downtime. The robots’ compatibility with existing machinery further reduced implementation costs, showcasing Doosan’s commitment to practical, scalable solutions.

Sustainability and Energy Efficiency

As industries prioritize sustainability, Doosan Robotics has responded with energy-efficient designs. Their E-Drive technology reduces power consumption by up to 30% compared to conventional models, aligning with global carbon reduction goals. In a partnership with a solar panel manufacturer, Doosan’s robots optimized material handling processes, cutting energy waste by 22% annually.

Moreover, the company’s focus on durability ensures longer robot lifespans, minimizing electronic waste. A lifecycle analysis revealed that Doosan’s cobots generate 40% less waste over a decade compared to industry averages, underscoring their environmental stewardship.

Future Horizons: From Factories to Everyday Life

Looking ahead, Doosan Robotics is expanding beyond industrial applications. Pilot projects in healthcare, such as robotic assistants for patient rehabilitation, demonstrate the potential for cobots in non-traditional settings. Similarly, partnerships with smart city developers aim to deploy robots for public services like waste management and infrastructure inspection.

The company’s R&D team is also exploring quantum computing integration to enhance real-time decision-making in robots. While still in experimental stages, this could revolutionize areas like autonomous logistics, where split-second adjustments are critical.

Doosan Robotics exemplifies how innovation, when aligned with user needs and sustainability, can drive meaningful progress. By blending collaborative design, AI, and modularity, the company is not just automating tasks—it’s empowering industries to evolve. As automation becomes ubiquitous, Doosan’s human-centric approach ensures that technology remains a tool for enhancement, not replacement, paving the way for a smarter, more efficient future.