As urbanization accelerates and climate challenges intensify, the demand for efficient waterway maintenance solutions has never been greater. Among emerging technologies, dredging robots stand out as a groundbreaking innovation, combining advanced engineering with environmental stewardship. This article explores the core technical advantages driving their adoption across industries.

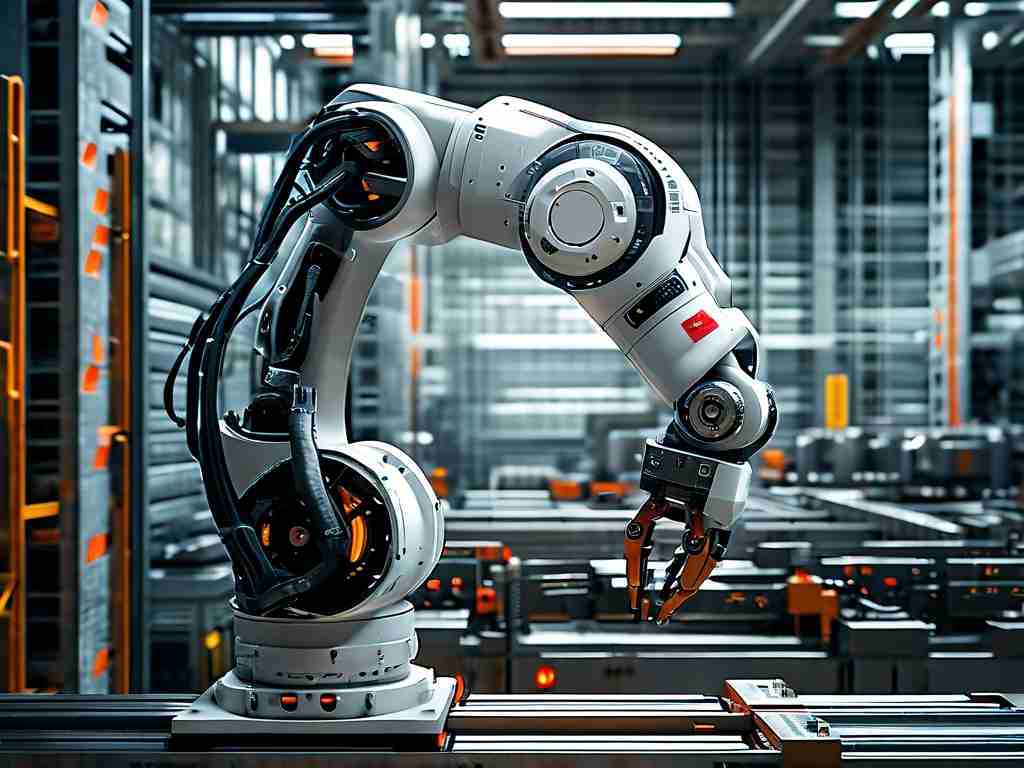

Precision Engineering for Complex Environments

Modern dredging robots integrate AI-powered navigation systems capable of mapping underwater terrain with millimeter-level accuracy. Unlike traditional dredging equipment that relies on manual operation, these autonomous machines use multi-sensor fusion technology – combining sonar, LiDAR, and inertial measurement units – to create real-time 3D models of sediment layers. This enables selective dredging operations that preserve delicate ecosystems while removing targeted debris.

A notable example is the adaptive suction mechanism employed in next-gen models. By dynamically adjusting flow rates and nozzle positions based on sediment density readings, these robots achieve 40% higher material recovery rates compared to conventional methods. Such precision minimizes unnecessary disturbance to aquatic habitats, addressing a longstanding criticism of hydraulic dredging practices.

Energy Efficiency Redefined

The latest generation of dredging robots incorporates hybrid power systems that combine electric propulsion with renewable energy harvesting. Solar panels integrated into floating platforms and regenerative braking systems in submersible units reduce operational carbon footprints by up to 65%. Field tests in the Port of Rotterdam demonstrated continuous 72-hour operation using only 30% battery capacity, achieved through optimized power management algorithms.

This energy-conscious design extends beyond propulsion. Smart sludge dewatering systems onboard these robots utilize passive filtration techniques inspired by mangrove root structures, cutting energy consumption in water separation processes by half. The result is a cleaner dredging process that aligns with global sustainability targets.

Adaptive Intelligence in Action

Machine learning algorithms give dredging robots unprecedented decision-making capabilities. Through continuous data analysis from onboard sensors and historical operation records, these systems can predict sediment accumulation patterns and optimize maintenance schedules. In Singapore's Marina Bay system, AI-enabled robots reduced routine maintenance frequency by 35% while improving water flow consistency.

The robots' modular design allows for rapid reconfiguration. Swappable toolkits enable quick transitions between different tasks – from removing industrial waste to harvesting organic sediments for agricultural use. This versatility makes them invaluable for diverse applications, from urban flood prevention to marine conservation projects.

Environmental Safeguards Built In

Beyond operational efficiency, dredging robots incorporate multiple ecological protection features. Real-time water quality monitoring systems automatically pause operations if turbidity levels exceed predetermined thresholds. Bio-friendly filtration membranes prevent aquatic organisms from entering suction mechanisms, with field trials showing 98% reduction in accidental marine life intake.

Perhaps most innovatively, some models now feature "ecological memory" functions. By cross-referencing dredging locations with marine biology databases, these robots avoid disturbing known spawning grounds or coral formations. This combination of proactive and reactive environmental protections sets a new standard for responsible infrastructure maintenance.

Economic Viability Meets Scalability

While the initial investment in robotic dredging systems appears substantial, lifecycle cost analysis reveals significant advantages. Automated systems operate continuously without crew requirements, reducing labor costs by approximately 60%. Predictive maintenance algorithms extend equipment lifespan – components like hydraulic seals last 3-5 times longer due to optimized pressure management.

Municipalities are particularly benefiting from scalable solutions. Compact robotic units can navigate narrow urban canals inaccessible to traditional dredgers, eliminating the need for costly infrastructure modifications. In Bangkok's historic klong network, robotic deployments completed a three-year maintenance backlog within eight months, demonstrating remarkable operational scalability.

As climate change increases sedimentation rates and environmental regulations tighten, dredging robots emerge as a critical solution balancing ecological responsibility with infrastructure needs. Their technical superiority lies not just in individual features, but in the synergistic integration of precision engineering, adaptive intelligence, and environmental consciousness – a blueprint for sustainable industrial innovation.