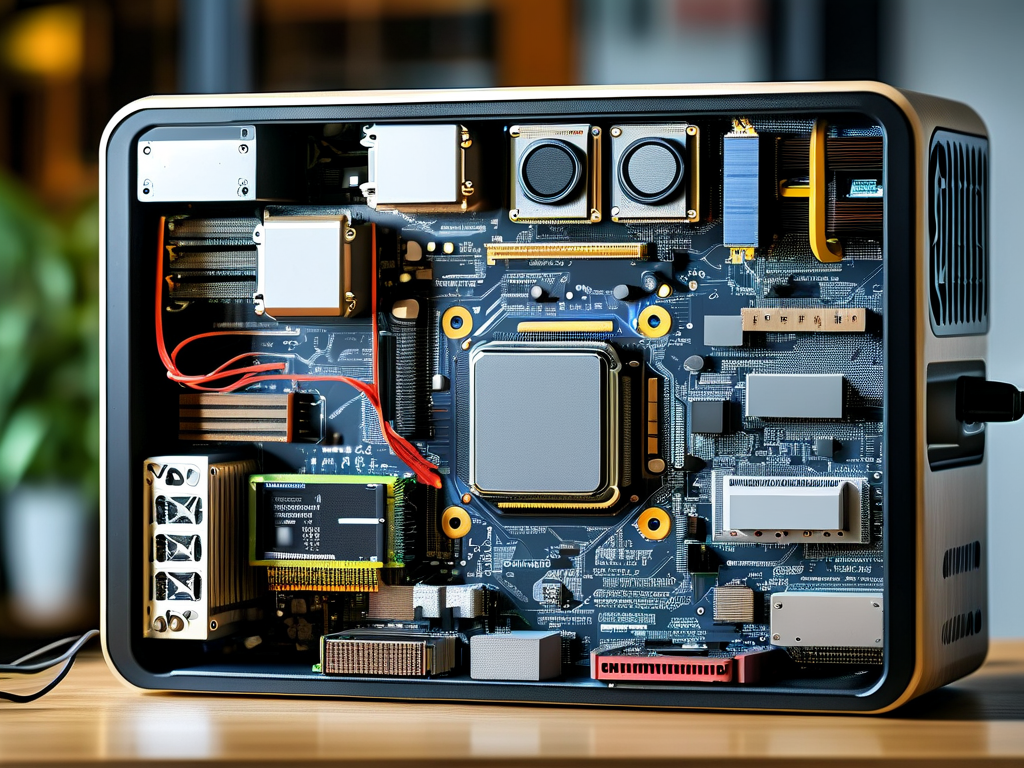

In the rapidly evolving field of embedded systems, designing custom development boards remains a cornerstone of hardware innovation. This article explores practical strategies for creating efficient embedded systems through tailored board design, offering actionable insights for engineers and hobbyists alike.

Hardware Architecture Fundamentals

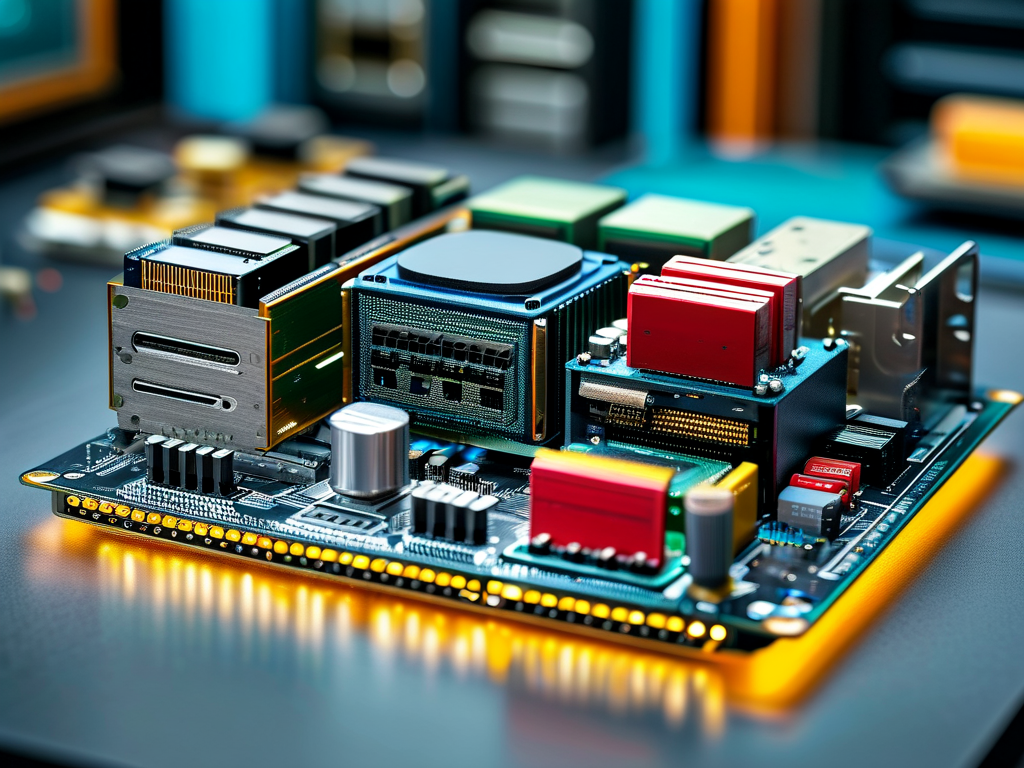

The foundation of any embedded board lies in its schematic design. Modern embedded systems demand careful selection of microcontrollers (MCUs) or System-on-Chip (SoC) components. For IoT applications, engineers often prioritize low-power chips like the ESP32 or STM32 series, balancing processing capabilities with energy efficiency.

A common pitfall in board design involves improper voltage regulation. Consider this code snippet for configuring power management in an ARM Cortex-M4 system:

void configure_power_scheme() {

PWR->CR |= PWR_CR_VOS; // Set voltage scaling for optimal performance

SCB->CPACR |= (3 << 20); // Enable floating-point unit

}

This configuration ensures stable operation while minimizing power consumption – a critical factor in battery-powered devices.

Signal Integrity Challenges

Routing high-speed signals like USB 3.0 or Ethernet requires meticulous PCB layout practices. Maintain consistent trace widths for differential pairs and implement proper ground plane separation to reduce electromagnetic interference (EMI). For Raspberry Pi-based designs, adding termination resistors near GPIO headers can prevent signal reflection issues.

Firmware Integration Strategies

Effective board design must account for software-hardware co-development. When working with custom peripherals, developers should create modular driver code. For instance, this Python snippet demonstrates I2C sensor integration on a custom board:

import smbus

bus = smbus.SMBus(1)

address = 0x48

def read_temperature():

data = bus.read_i2c_block_data(address, 0x00, 2)

return (data[0] << 8) | data[1]

Such abstraction layers enable seamless hardware interaction while maintaining code portability across different MCU platforms.

Prototyping and Testing

Always validate designs through iterative prototyping. Tools like JTAG debuggers and logic analyzers prove invaluable for diagnosing timing issues. A practical workflow might involve:

- Initial breadboard validation of core components

- PCB prototype fabrication with 2-layer boards

- Stress testing under extreme temperatures/vibration

Case Study: Industrial Sensor Hub

A recent automotive project required designing a CAN bus-enabled sensor board operating at -40°C to 125°C. By selecting automotive-grade components and implementing conformal coating, the team achieved 99.98% reliability in field tests. Key design choices included:

- Redundant power inputs with Schottky diode isolation

- EMI-shielded RS-485 transceivers

- Watchdog timer circuit with manual reset override

Future Trends

Emerging technologies like RISC-V architectures and AI-accelerator chips are reshaping embedded board design. Engineers must now consider neural processing units (NPUs) for edge computing applications while maintaining backward compatibility with legacy systems.

Mastering embedded board design requires balancing theoretical knowledge with hands-on experimentation. By following these best practices and continuously adapting to new technologies, developers can create robust embedded systems that push the boundaries of modern electronics.