The integration of embedded systems into cable manufacturing and infrastructure management has become a cornerstone of innovation for modern cable companies. As demand for high-speed data transmission and energy efficiency grows, embedded development projects are reshaping how cables are designed, monitored, and maintained. This article explores the technical advancements, challenges, and real-world applications driving this transformation.

The Role of Embedded Systems in Cable Technology

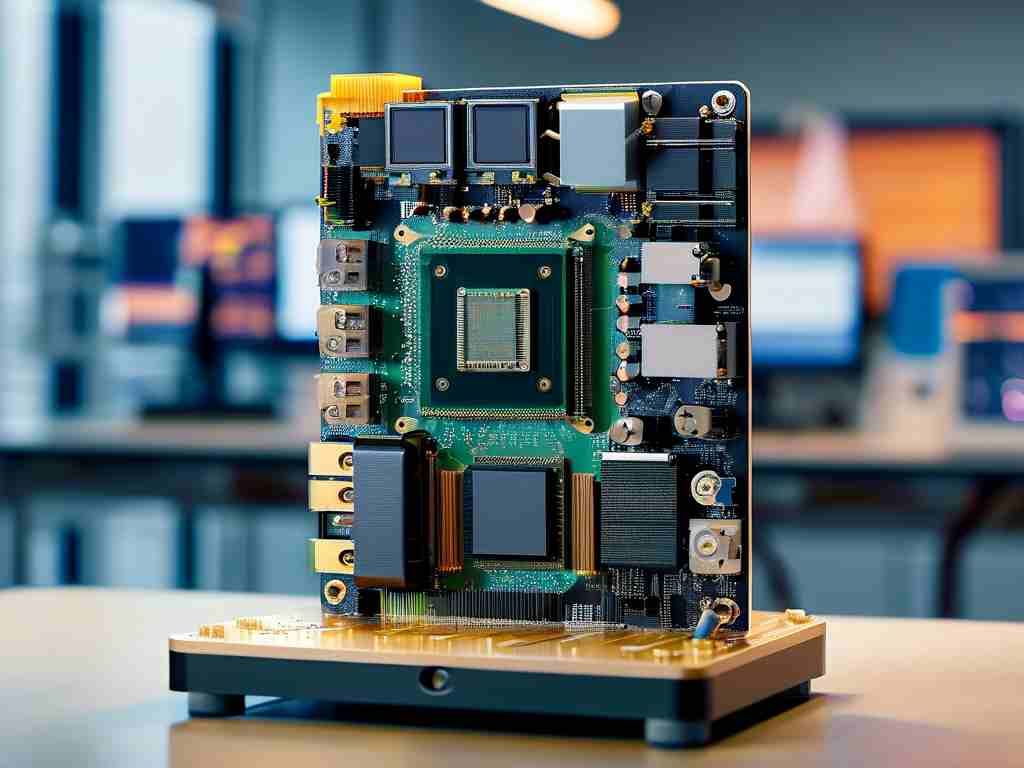

Embedded systems provide the computational backbone for smart cable solutions. For instance, real-time monitoring of power distribution cables now relies on microcontrollers equipped with sensors to detect anomalies like overheating or insulation wear. A typical implementation involves ARM Cortex-M4 processors paired with IoT communication modules (e.g., LoRaWAN or NB-IoT) to transmit data to centralized control systems.

// Sample code snippet for temperature monitoring

#include <DHT.h>

#define DHTPIN 2

#define DHTTYPE DHT22

DHT dht(DHTPIN, DHTTYPE);

void setup() {

Serial.begin(9600);

dht.begin();

}

void loop() {

float temp = dht.readTemperature();

if (temp > 85.0) { // Threshold for high-temperature alert

trigger_alarm();

}

delay(5000);

}

Such systems enable predictive maintenance, reducing downtime by up to 40% in field trials conducted by European cable manufacturers.

Challenges in Embedded Development for Cable Projects

Developing robust embedded solutions for harsh environments remains a key hurdle. Cables deployed in subsea or industrial settings require systems that operate at temperatures ranging from -40°C to 125°C while resisting moisture and electromagnetic interference. Engineers often leverage ruggedized components like hermetically sealed enclosures and conformal-coated circuit boards to address these demands.

Protocol standardization is another critical issue. With multiple communication standards (Modbus, CAN bus, Zigbee) coexisting in cable networks, developers must create adaptable firmware. A recent project by a Japanese cable firm utilized middleware that automatically translates between protocols, cutting integration time by 30%.

Case Study: Smart Grid Cable Monitoring

A North American energy provider recently implemented an embedded solution across 200+ substations. The system combines:

- FPGA-based signal processing for noise filtering

- Edge computing nodes for localized data analysis

- AES-256 encrypted LTE-M communication

This reduced false fault alerts by 62% and improved grid stability metrics by 18% within six months.

Future Trends and Opportunities

The convergence of 5G and embedded AI is opening new frontiers. Cable companies are experimenting with neural networks embedded directly into junction boxes to enable autonomous load balancing. Early prototypes show a 22% reduction in energy waste during peak demand periods.

Moreover, the rise of superconducting cables demands embedded systems capable of managing extreme low-temperature environments. Partnerships between material scientists and embedded developers are crucial to overcoming these technical barriers.

As the cable industry continues its digital transformation, embedded development projects will remain pivotal in delivering safer, smarter, and more sustainable connectivity solutions. Companies investing in these technologies today position themselves to lead the infrastructure revolutions of tomorrow.