Embedded hardware development has become a cornerstone of technological innovation across industries, and Foshan, a manufacturing powerhouse in China, is emerging as a hub for cutting-edge solutions in this field. This article explores the unique advantages and methodologies behind Foshan’s embedded hardware development strategies, offering insights for businesses aiming to leverage these advancements.

Why Foshan Stands Out in Embedded Hardware Development

Foshan’s robust industrial ecosystem, coupled with its focus on smart manufacturing, positions it as a leader in embedded systems. The city’s integration of hardware and software expertise enables the creation of tailored solutions for applications ranging from consumer electronics to industrial automation. Local developers prioritize scalability, energy efficiency, and cost-effectiveness, ensuring that embedded systems meet both current and future demands.

Key Components of Foshan’s Development Framework

-

Customized Design Processes

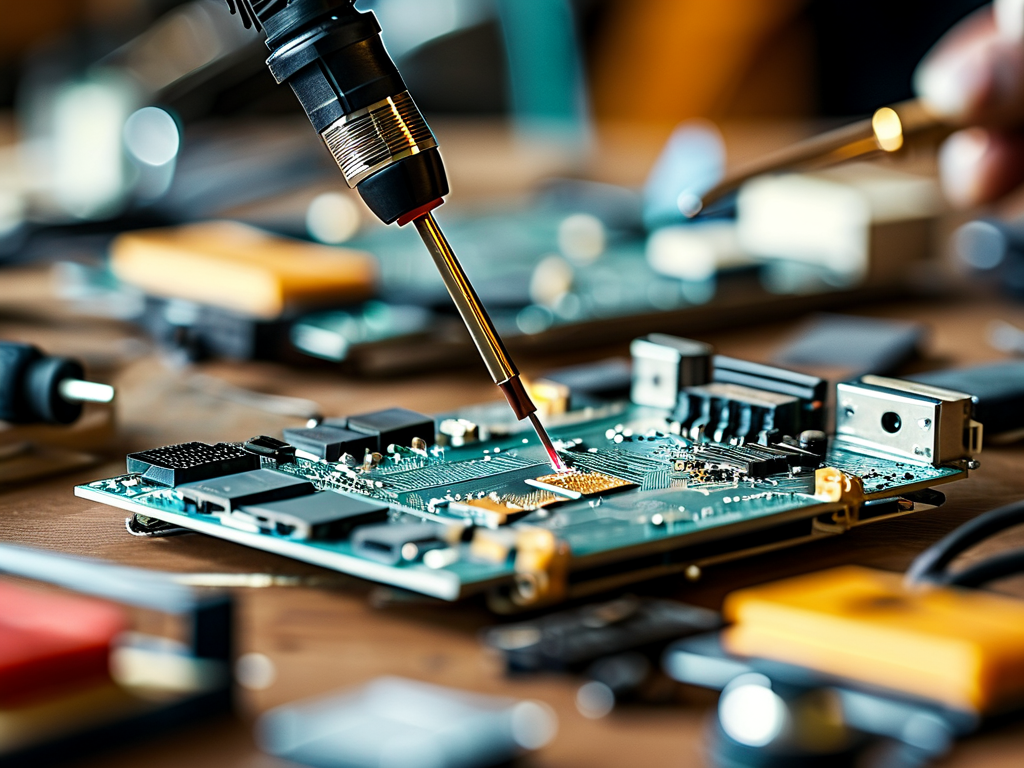

Foshan-based teams emphasize modular design principles, allowing for rapid prototyping and iterative testing. For instance, a typical workflow might involve:// Example code snippet for sensor data processing void processSensorData(int sensorValue) { if (sensorValue > threshold) { triggerActuator(); } }This approach reduces time-to-market while maintaining flexibility for client-specific modifications.

-

Cross-Industry Collaboration

Local firms actively collaborate with automotive, IoT, and robotics sectors to address shared challenges. A recent project involved co-developing a low-power embedded controller for smart home devices, which reduced energy consumption by 40% compared to conventional designs.

Overcoming Technical Challenges

Foshan’s developers tackle common hurdles such as signal interference and thermal management through innovative techniques. For example, multilayer PCB designs with optimized grounding schemes are now standard for high-frequency applications. Advanced simulation tools like ANSYS HFSS are employed to predict and mitigate electromagnetic compatibility (EMC) issues early in the design phase.

Case Study: Industrial IoT Gateway Development

A Foshan-based company recently delivered an embedded gateway solution for factory automation. Key features included:

- Dual-band Wi-Fi and 5G connectivity

- Real-time data encryption

- Operating temperature range of -40°C to 85°C

The project achieved a 30% reduction in latency while maintaining compliance with industrial safety standards.

Future Trends and Opportunities

With the rise of edge computing and AIoT (AI + IoT), Foshan’s developers are integrating machine learning accelerators into embedded systems. A notable trend is the adoption of RISC-V architecture for customizable processor designs, which aligns with the growing demand for domain-specific hardware.

Foshan’s embedded hardware development solutions combine technical excellence with practical industry knowledge, making the city a go-to destination for businesses seeking reliable and innovative embedded systems. By staying ahead of technological curves and fostering collaborative ecosystems, Foshan continues to redefine what’s possible in hardware-driven innovation.