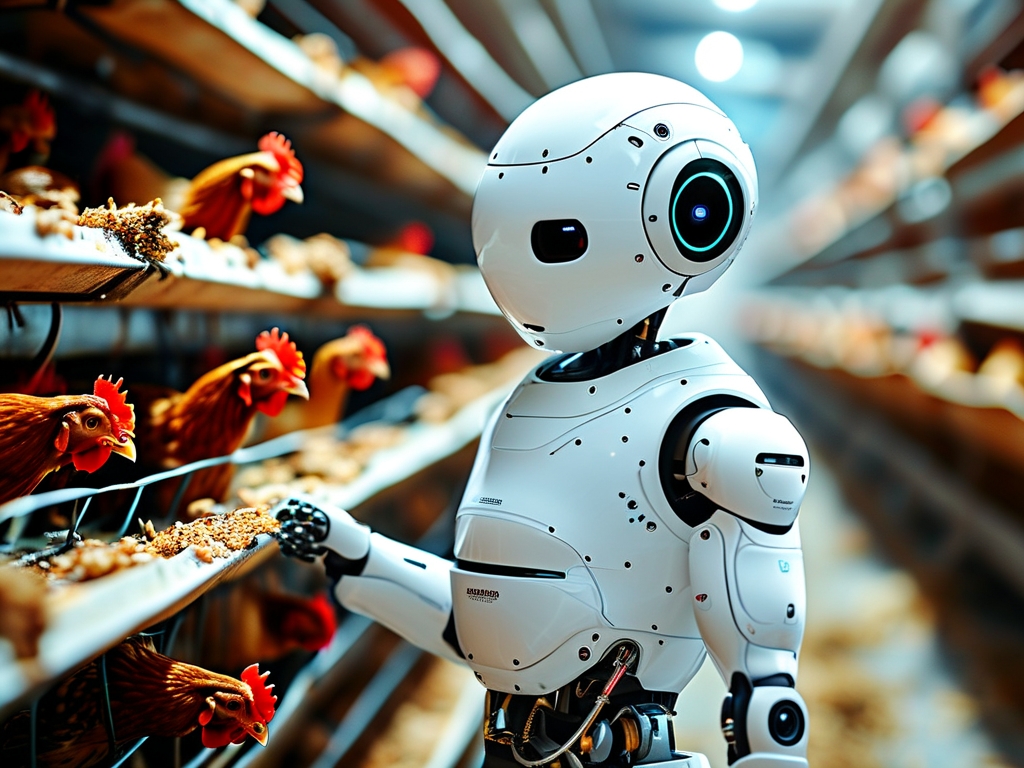

With the rapid advancement of agricultural automation, robotic chicken farming has emerged as a groundbreaking solution to modernize poultry management. This technology integrates artificial intelligence, IoT sensors, and mechanical automation to optimize every stage of poultry production, from feeding to disease prevention. Below, we explore the core principles driving this innovation and its transformative impact on the industry.

Core Components of Robotic Systems

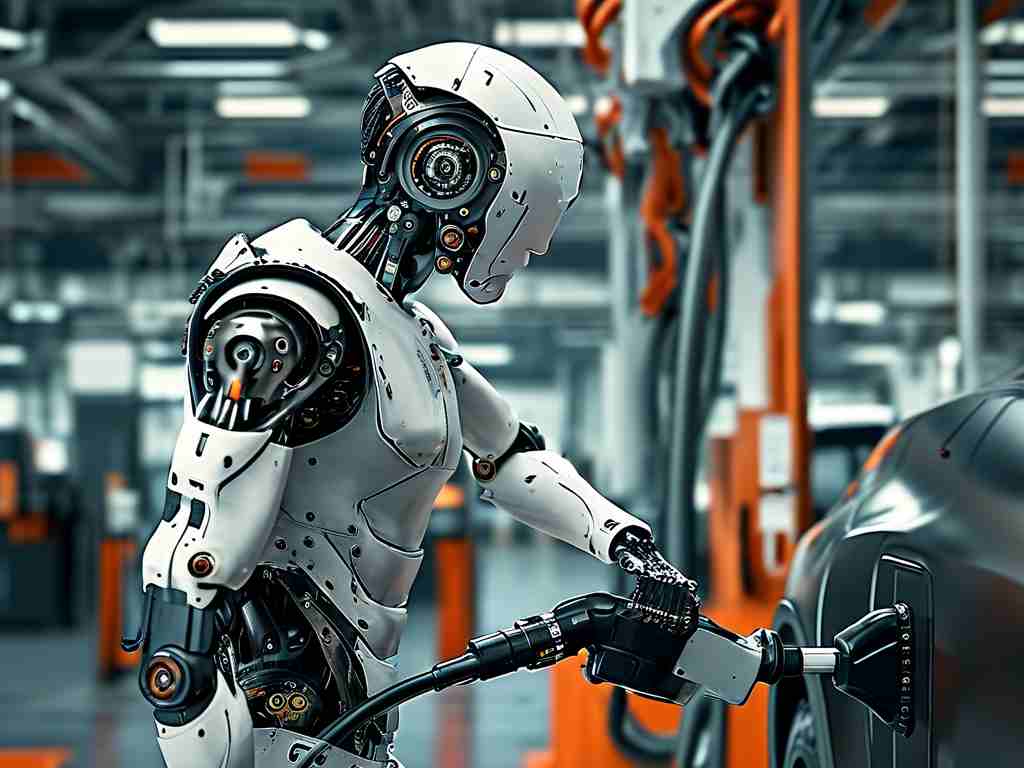

At the heart of robotic chicken farming are three interconnected systems: environmental monitoring, automated feeding/cleaning, and health analytics. Environmental sensors track temperature, humidity, and air quality in real time, adjusting ventilation or heating systems automatically to maintain ideal conditions. For instance, if ammonia levels rise due to waste accumulation, robotic scrubbers activate to sanitize coops without human intervention.

Automated feeders use precision dosing mechanisms to distribute customized feed blends based on the age and health status of the flock. A study by the Poultry Science Association found that such systems reduce feed waste by 18% compared to manual methods. Meanwhile, self-cleaning conveyor belts remove manure and debris, minimizing contamination risks.

AI-Driven Health Management

Machine learning algorithms analyze data from cameras and wearable poultry trackers to detect early signs of illness or stress. For example, changes in movement patterns or vocalizations can flag potential outbreaks of avian influenza. In one case, a farm in the Netherlands reduced mortality rates by 22% after implementing AI-powered diagnostics that identified lethargic birds for quarantine.

Robotic arms equipped with thermal imaging cameras also perform non-invasive health checks. These devices scan flocks during nighttime hours when chickens are less active, ensuring minimal disruption.

Energy Efficiency and Sustainability

Solar-powered robots are increasingly deployed to cut operational costs. A prototype developed by AgriTech Robotics in 2023 uses photovoltaic panels to power its daily 12-hour cleaning cycle, slashing energy consumption by 40%. Additionally, automated systems recycle poultry waste into biofertilizers, aligning with circular economy principles.

Challenges and Future Outlook

Despite its benefits, robotic farming faces hurdles such as high upfront costs and the need for specialized maintenance. Small-scale farmers may struggle to adopt these technologies without subsidies or cooperative purchasing models. However, startups like CluckTech are addressing this by offering robotics-as-a-service (RaaS) plans, where farmers pay monthly fees instead of purchasing equipment outright.

Looking ahead, researchers aim to enhance swarm robotics—deploying multiple small robots to collaborate on tasks like egg collection. Trials in Japan have shown that swarm systems can harvest 500 eggs per hour with 99.8% accuracy, far surpassing human capabilities.

In , robotic chicken farming represents a paradigm shift in agriculture, merging sustainability with precision. As AI and hardware continue to evolve, this technology promises to redefine global food production standards while addressing labor shortages and ethical concerns in poultry farming.