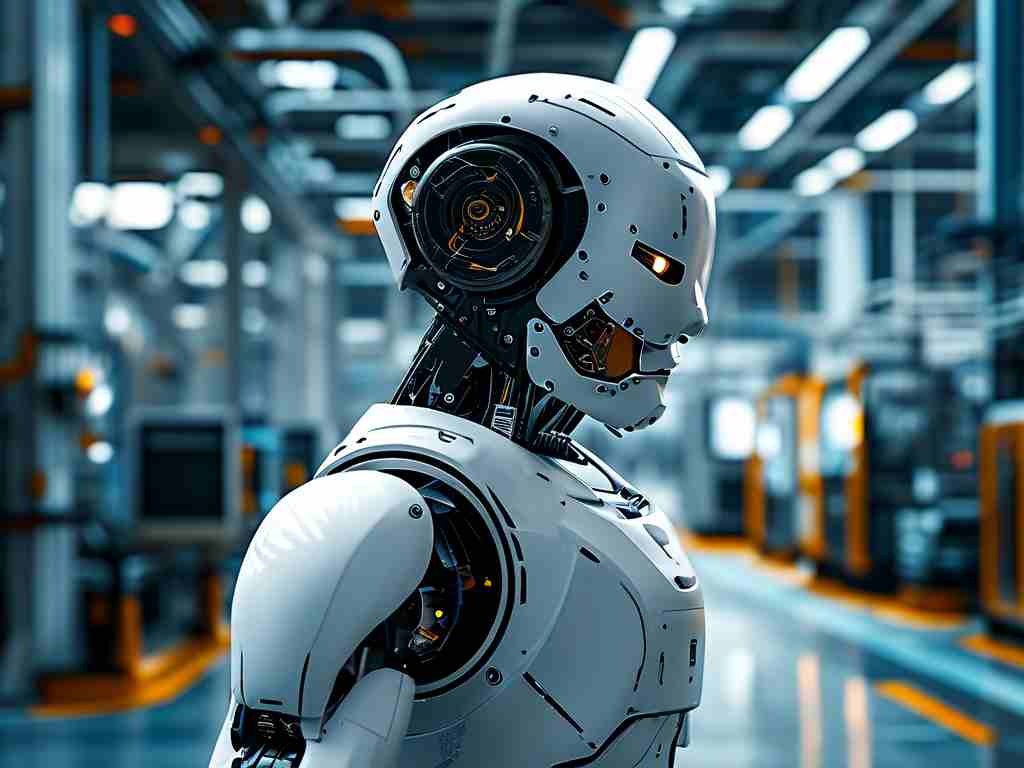

Industrial robotics technology has emerged as a cornerstone of modern manufacturing, driving efficiency, precision, and innovation across industries. For vocational education institutions, integrating this technology into curricula is no longer optional-it is essential to prepare students for the demands of a rapidly evolving industrial landscape. This article explores the significance of industrial robotics in vocational training, its applications, challenges, and future prospects.

The Rise of Industrial Robotics

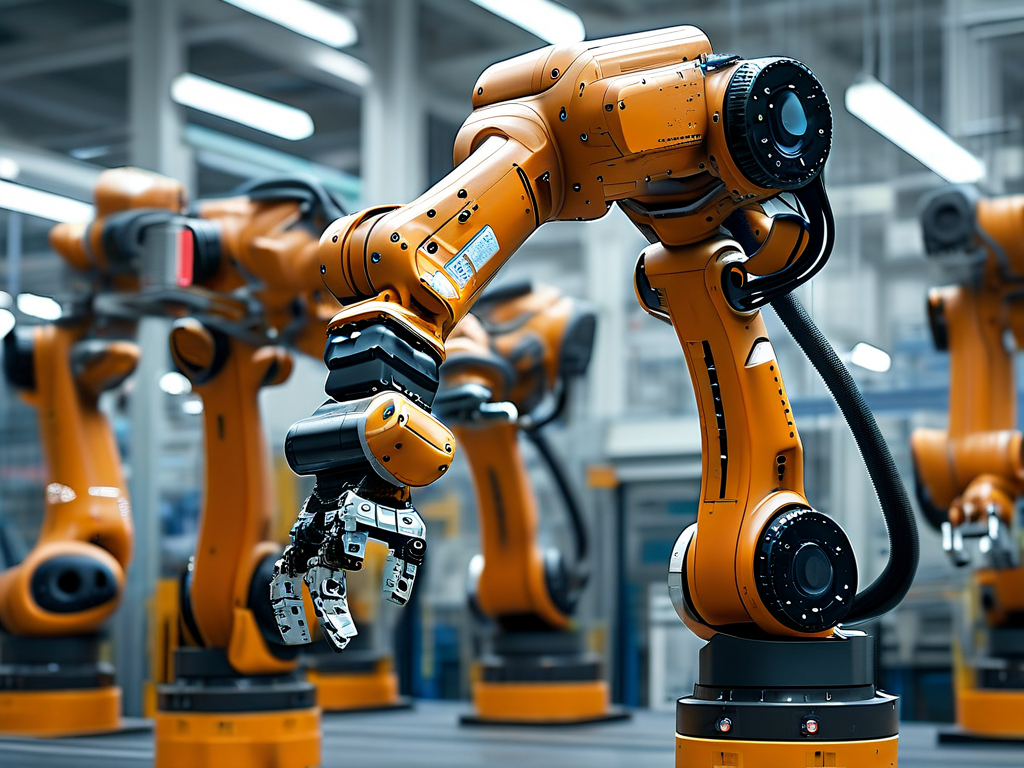

Industrial robots, defined as programmable machines capable of automating complex tasks, have revolutionized manufacturing. From automotive assembly lines to electronics production, robots handle repetitive, hazardous, or high-precision tasks with unmatched consistency. According to the International Federation of Robotics (IFR), over 3 million industrial robots were operational worldwide in 2022, with annual installations growing by 12%. This surge underscores the need for skilled technicians who can design, operate, and maintain these systems.

Vocational Education: A Catalyst for Workforce Development

Vocational colleges play a pivotal role in bridging the skills gap. Unlike traditional academic programs, vocational training emphasizes hands-on experience, aligning education with industry needs. Courses in industrial robotics typically cover:

- Robot Programming: Teaching students to code robots using languages like Python, C++, or proprietary software.

- System Integration: Training learners to integrate robots with sensors, conveyors, and IoT-enabled devices.

- Maintenance and Troubleshooting: Equipping students with skills to diagnose mechanical or software issues.

- Safety Protocols: Ensuring compliance with industrial safety standards, such as ISO 10218.

For example, Germany's dual education system combines classroom instruction with apprenticeships, producing technicians who are job-ready. Similarly, vocational schools in Japan collaborate with companies like Fanuc and Yaskawa to provide cutting-edge robotics training.

Applications Across Industries

Industrial robotics is not limited to manufacturing. Key sectors benefiting from this technology include:

- Healthcare: Surgical robots like the da Vinci System enhance precision in operations.

- Agriculture: Autonomous drones and harvesters optimize crop management.

- Logistics: Warehouse robots, such as Amazon's Kiva systems, streamline order fulfillment. Vocational graduates skilled in robotics can thus explore diverse career paths, from factory floors to R&D labs.

Challenges in Implementation

Despite its potential, integrating robotics into vocational education faces hurdles:

- High Costs: Industrial robots and simulation software require significant investment.

- Rapid Technological Change: Curricula must evolve alongside advancements in AI and machine learning.

- Faculty Training: Instructors need continuous upskilling to stay abreast of new tools. To address these, governments and private sectors are partnering with schools. For instance, the U.S. National Robotics Initiative funds educational programs, while companies like ABB and KUKA donate equipment to colleges.

The Future of Robotics in Vocational Training

The Fourth Industrial Revolution (Industry 4.0) demands a workforce fluent in smart manufacturing technologies. Vocational institutions are adopting trends such as:

- Collaborative Robots (Cobots): These user-friendly robots work alongside humans, ideal for SMEs.

- Digital Twins: Virtual simulations allow students to test robot configurations risk-free.

- AI-Driven Automation: Machine learning algorithms enable predictive maintenance and adaptive workflows.

Moreover, certifications from organizations like the Robotics Industries Association (RIA) enhance graduates' employability. As automation expands, vocational training will remain critical to sustaining global competitiveness.

Industrial robotics technology is reshaping industries, and vocational education is the linchpin for cultivating the next generation of technicians. By combining theoretical knowledge with practical experience, vocational programs empower students to thrive in an automated world. As schools and industries collaborate, the synergy between education and innovation will drive progress, ensuring that no worker is left behind in the age of robotics.