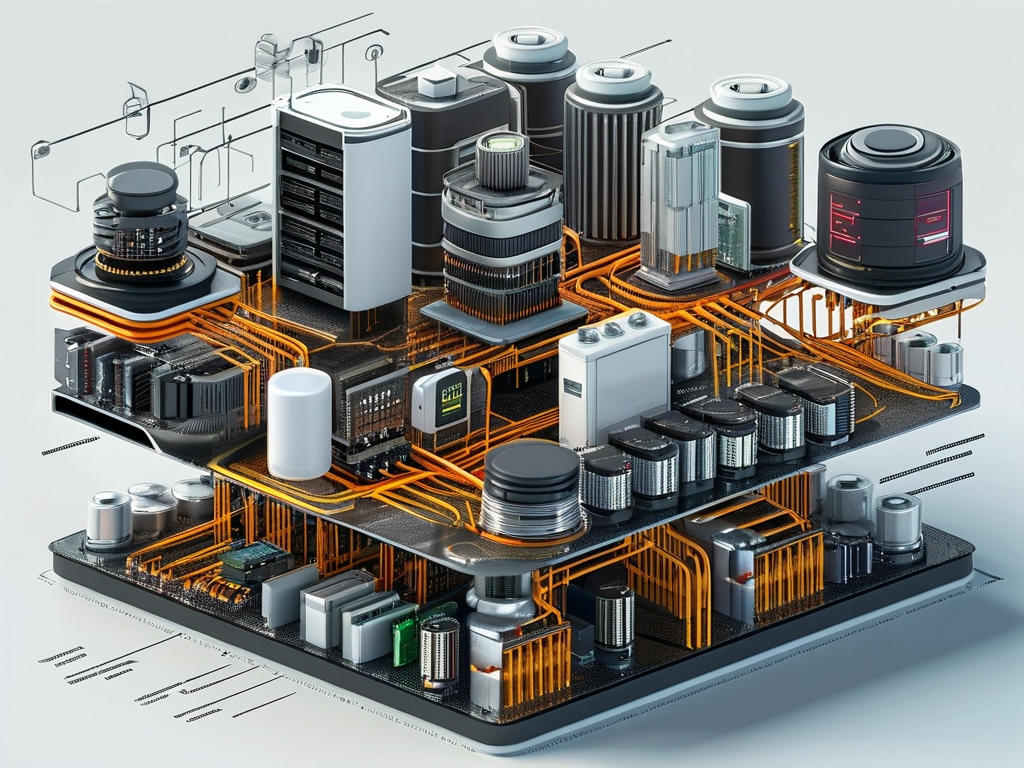

The rapid development of electric vehicles (EVs) has introduced complex engineering challenges, particularly in designing efficient and scalable architectures. A distributed architecture diagram is critical for visualizing how components like batteries, motors, controllers, and software systems interact. This article provides a comprehensive guide to creating such diagrams, ensuring clarity for engineers, designers, and stakeholders.

1. Understanding Distributed Architecture in EVs

Distributed architectures in EVs decentralize control systems, allowing components to operate semi-independently while communicating via networks like CAN (Controller Area Network) or Ethernet. Unlike centralized systems, this approach improves fault tolerance, scalability, and modularity. Key subsystems include:

- Battery Management System (BMS): Manages cell balancing and thermal regulation.

- Motor Control Unit (MCU): Governs torque and speed.

- Vehicle Control Unit (VCU): Acts as the central decision-making hub.

- Infotainment and Telematics: Handles user interfaces and connectivity.

2. Preparing to Draw the Diagram

Step 1: Identify Components and Relationships

Start by listing all hardware and software components. For example:

- Power Distribution Module: Links batteries to inverters and chargers.

- Sensors: Temperature, voltage, and speed sensors.

- Communication Protocols: CAN, LIN, or Ethernet. Map dependencies-e.g., how the BMS shares data with the VCU.

Step 2: Choose a Diagramming Tool

Use specialized tools like:

- Lucidchart or Visio: For basic block diagrams.

- Enterprise Architect or SysML: For UML-based system modeling.

- MATLAB/Simulink: For simulating interactions.

Step 3: Define Layers and Abstraction Levels

Break the diagram into layers:

- Physical Layer: Hardware components (batteries, motors).

- Network Layer: Communication buses and protocols.

- Application Layer: Software modules (e.g., autonomy algorithms).

3. Drawing the Diagram: Best Practices

- Modularity: Group related components (e.g., powertrain systems).

- Color Coding: Use colors to differentiate power flow (red), data flow (blue), and control signals (green).

- Annotations: Add brief descriptions for protocols (e.g., "CAN bus @ 500 kbps").

- Interfaces: Highlight APIs or middleware (e.g., ROS for autonomous functions).

Example: A Simplified EV Architecture Diagram

- Top Section: Place the VCU at the center, connected to the BMS and MCU.

- Left Side: Show the charging port linked to the BMS via CAN.

- Right Side: Connect the MCU to wheel motors and regenerative braking.

- Bottom Layer: Include infotainment systems interfacing with cloud services.

4. Addressing Common Challenges

- Complexity Management: Avoid overcrowding by creating sub-diagrams for subsystems.

- Real-Time Requirements: Mark time-sensitive interactions (e.g., brake-by-wire systems).

- Scalability: Leave room for future additions (e.g., V2X communication modules).

5. Case Study: Tesla's Distributed Architecture

Tesla's architecture uses zonal controllers to reduce wiring and improve redundancy. Their diagrams emphasize:

- Zone Controllers: Managing specific regions (front, rear) of the vehicle.

- Over-the-Air (OTA) Updates: Highlighting software integration paths.

- Autopilot Integration: Separating AI inference engines from sensor networks.

6. Validating and Iterating

Share the diagram with cross-functional teams to identify gaps. For instance:

- Electrical Engineers: Verify power distribution accuracy.

- Software Developers: Ensure API compatibility.

- Safety Teams: Confirm fail-safe mechanisms are visible.

7. Tools for Advanced Visualization

For autonomous or connected EVs, consider:

- 3D Modeling: Tools like SolidWorks to map spatial relationships.

- Digital Twins: Siemens NX or ANSYS for real-time simulation.

A well-designed distributed architecture diagram is indispensable for EV innovation. By following structured steps and leveraging modern tools, teams can streamline development, reduce errors, and foster collaboration. As EVs evolve toward autonomy and connectivity, these diagrams will remain foundational to engineering success.

Word Count: 1,028