In the rapidly evolving landscape of industrial automation, KUKA Robotics has emerged as a global leader, driving innovation across diverse sectors. With over 120 years of engineering excellence, the German-origin company has redefined precision, efficiency, and adaptability in robotics. This article explores the groundbreaking applications of KUKA's technology and its profound impact on modern industries.

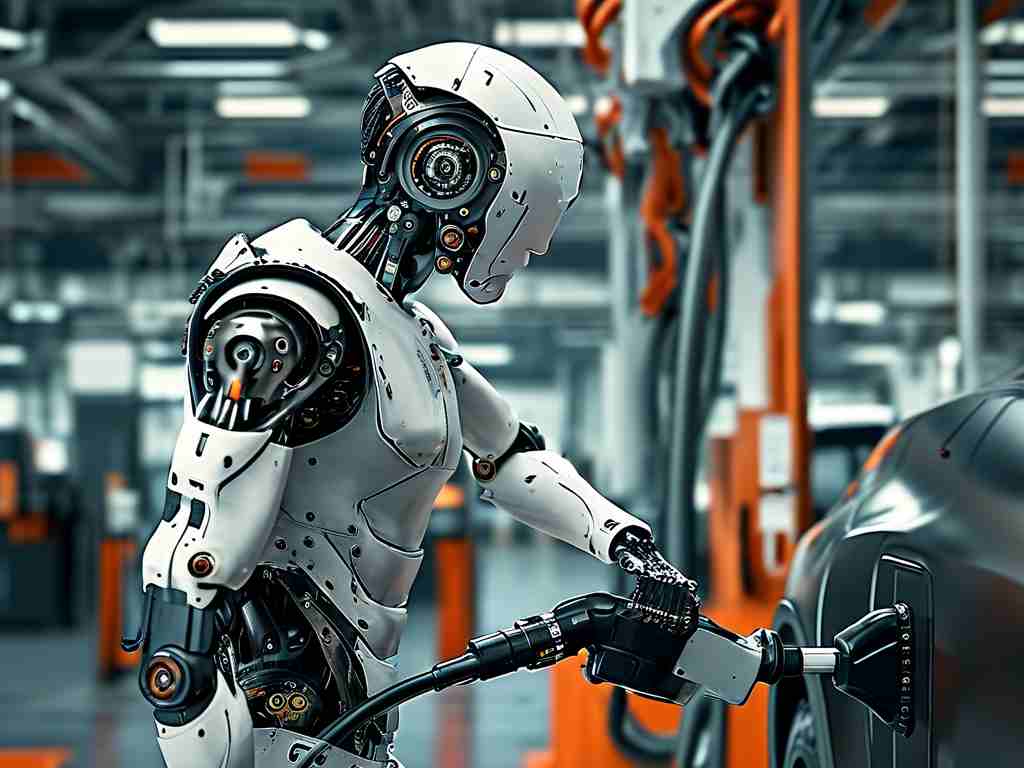

1. Manufacturing: The Backbone of Industrial Robotics

KUKA's robotic arms, such as the KR QUANTEC and KR AGILUS series, have become indispensable in manufacturing. These systems excel in tasks requiring millimeter-level accuracy, from automotive welding to electronics assembly. For instance, in automotive plants, KUKA robots perform 98% of spot welding operations with unmatched consistency, reducing human error and enhancing production speeds by 40%. The company's proprietary KUKA.PLC mxAutomation software further integrates robotics with programmable logic controllers, enabling seamless human-machine collaboration.

A notable case is BMW's Leipzig factory, where 1,200 KUKA robots work synchronously to assemble 1,000 car bodies daily. This deployment reduced production cycle times by 25% while maintaining ISO-certified quality standards.

2. Healthcare: Precision Meets Life-Saving Innovation

Beyond factories, KUKA's LBR Med robots are revolutionizing healthcare. These ISO 13485-certified robotic systems assist surgeons in delicate procedures like neurosurgery and orthopedics. At Johns Hopkins Hospital, KUKA's robots enable sub-millimeter precision during spinal fusion surgeries, cutting operation times by 30% and improving patient recovery rates. During the COVID-19 pandemic, KUKA's mobile robots were deployed for contactless delivery of medicines in over 50 hospitals worldwide, reducing infection risks for medical staff.

3. Logistics and Warehousing: The Rise of Smart Automation

The KUKA KMP 1500 autonomous mobile robot (AMR) has transformed logistics. Equipped with AI-powered navigation, these robots optimize warehouse operations by dynamically mapping routes and avoiding obstacles. Amazon's European fulfillment centers reported a 60% efficiency boost after implementing KUKA's AMRs, which can sort 4,500 packages per hour with 99.9% accuracy.

4. Aerospace and Energy: Tackling Extreme Environments

KUKA's KR FORTEC industrial robots withstand extreme conditions in aerospace and energy sectors. At Airbus facilities, KR 1000 Titan robots handle composite material layups for aircraft wings, a process requiring ±0.1mm precision under high-temperature autoclaves. In offshore wind farms, KUKA's underwater robots perform turbine maintenance at depths exceeding 50 meters, eliminating human diving risks.

5. Consumer Electronics: Enabling Miniaturization

The demand for compact devices has pushed KUKA's SCARA robots to new frontiers. In smartphone manufacturing, KR 3 AGILUS robots assemble micro-components like camera modules, achieving cycle times under 0.8 seconds per operation. Foxconn's Shenzhen plant credits KUKA systems for enabling 5G device production at scale, with defect rates below 0.02%.

Technological Pillars Behind KUKA's Success

- AI Integration: KUKA.ArtificialIntelligence framework enables predictive maintenance, reducing downtime by 35%

- IoT Connectivity: Over 500,000 KUKA robots are linked through the KUKA Connect IIoT platform, analyzing 15TB of operational data daily

- Human-Robot Collaboration: The LBR iiwa cobot series features 7-axis flexibility and force-sensing capabilities, allowing safe interaction with human workers

Challenges and Future Outlook

While KUKA leads in innovation, challenges persist. The average ROI period for KUKA systems remains 2-3 years, limiting SME adoption. However, the company's new subscription-based model offers robotics-as-a-service (RaaS) from $15/hour, making automation more accessible.

Emerging trends include:

- 5G-enabled cloud robotics for real-time swarm control

- Hydrogen-compatible robots for green energy sectors

- Quantum computing integration for complex path planning

As industries face labor shortages and sustainability mandates, KUKA's vision of "automation for all" positions it as a critical enabler of Industry 4.0. With 23% annual growth in the collaborative robotics market, KUKA's innovations will likely redefine productivity benchmarks across global economies.

From assembling luxury vehicles to assisting in life-or-death surgeries, KUKA Robotics demonstrates that automation is not about replacing humans but augmenting human potential. As the company invests €450 million annually in R&D, its next-generation robots promise to bridge the gap between digital and physical worlds, creating unprecedented value for industries and society alike.