The rapid evolution of robotics and automation has ushered in groundbreaking advancements across industries, and the field of underground infrastructure is no exception. Robotic trenchless technology, a cutting-edge approach to installing, repairing, and maintaining subterranean systems without extensive excavation, is transforming how cities manage utilities, pipelines, and communication networks. This article explores the mechanics, applications, benefits, and future prospects of this innovative technology.

Understanding Robotic Trenchless Technology

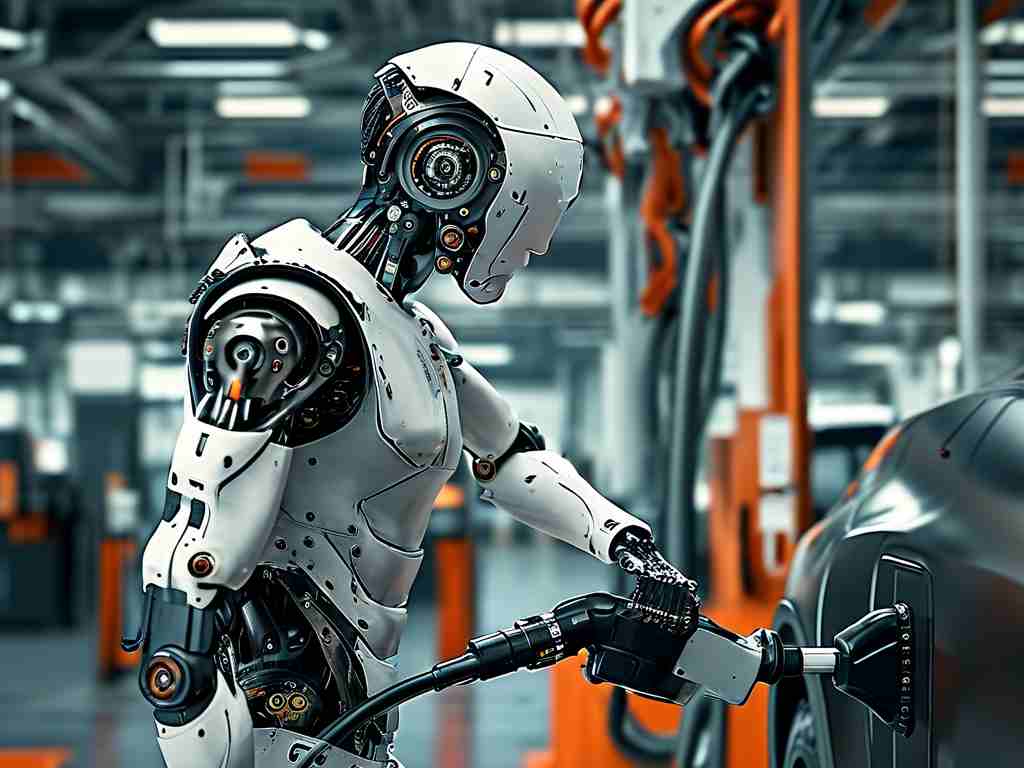

Trenchless technology refers to methods that minimize surface disruption by avoiding large-scale digging. Traditional excavation techniques often lead to road closures, environmental damage, and high costs. Robotic trenchless solutions take this concept further by integrating autonomous or semi-autonomous machines equipped with advanced sensors, cameras, and artificial intelligence (AI). These robots perform tasks such as pipe inspection, rehabilitation, and installation with unparalleled precision.

Key components of robotic trenchless systems include:

- Robotic Crawlers: Compact, remotely operated devices that navigate through pipelines to assess conditions or execute repairs.

- AI-Driven Diagnostics: Machine learning algorithms analyze real-time data to detect cracks, blockages, or corrosion.

- 3D Mapping Tools: Laser scanners and LiDAR create detailed maps of underground networks.

- Non-Invasive Repair Mechanisms: Methods like cured-in-place pipe (CIPP) lining or robotic welding fix issues without replacing entire sections.

Applications Across Industries

Robotic trenchless technology is versatile, addressing challenges in multiple sectors:

1. Urban Utilities Cities rely on aging water, gas, and sewage systems. Robotic crawlers inspect miles of pipes annually, identifying leaks or structural weaknesses. For example, in Tokyo, AI-equipped robots reduced water loss by 30% in two years by pinpointing invisible cracks.

2. Telecommunications Fiber-optic networks require minimal disruption during installation. Trenchless robots lay cables underground by drilling horizontal paths, avoiding road cuts. This method accelerated 5G deployment in Seoul, South Korea, by 40%.

3. Environmental Protection Conventional excavation risks contaminating soil and groundwater. Robotic systems rehabilitate oil and gas pipelines without disturbing ecosystems. In Canada, trenchless robots repaired a corroded pipeline beneath a protected forest, preventing potential spills.

4. Disaster Response After earthquakes or floods, underground infrastructure often suffers hidden damage. Rapid robotic assessments enable targeted repairs, as seen in post-hurricane recovery efforts in Florida.

Advantages Over Traditional Methods

The benefits of robotic trenchless technology are compelling:

- Cost Efficiency: Reduced labor and restoration expenses save up to 50% compared to excavation.

- Minimal Disruption: Roads, landscapes, and communities remain intact, preserving economic activity.

- Enhanced Safety: Workers avoid hazardous environments like unstable trenches or toxic gas zones.

- Sustainability: Lower carbon emissions and resource consumption align with global green initiatives.

Challenges and Limitations

Despite its promise, the technology faces hurdles:

- High Initial Investment: Advanced robotics and AI systems require significant upfront costs.

- Technical Complexity: Operators need specialized training to interpret data and manage equipment.

- Regulatory Barriers: Outdated policies in some regions delay adoption.

- Material Limitations: Certain pipe materials or diameters may still require hybrid approaches.

The Future of Robotic Trenchless Systems

Innovations on the horizon could amplify the impact of this technology:

- Swarm Robotics: Teams of micro-robots collaborating on large-scale projects.

- Self-Healing Materials: Pipes embedded with sensors that trigger automatic repairs.

- Quantum Computing: Faster data processing for real-time decision-making in complex networks.

- Global Standards: Unified guidelines to streamline cross-border infrastructure projects.

Governments and corporations are increasingly investing in R&D. The European Union's "Smart Underground Networks 2030" initiative aims to automate 70% of utility maintenance using robotics. Similarly, startups like TrenchlessAI are developing affordable robotic kits for small municipalities.

Robotic trenchless technology represents a paradigm shift in infrastructure management. By merging robotics, AI, and sustainable practices, it addresses urbanization challenges while safeguarding the environment. As adoption grows, cities will become more resilient, efficient, and adaptable to future demands. The era of disruptive excavation is ending-ushering in an age where robots work silently beneath our feet, ensuring the lifelines of modern society remain robust and reliable.