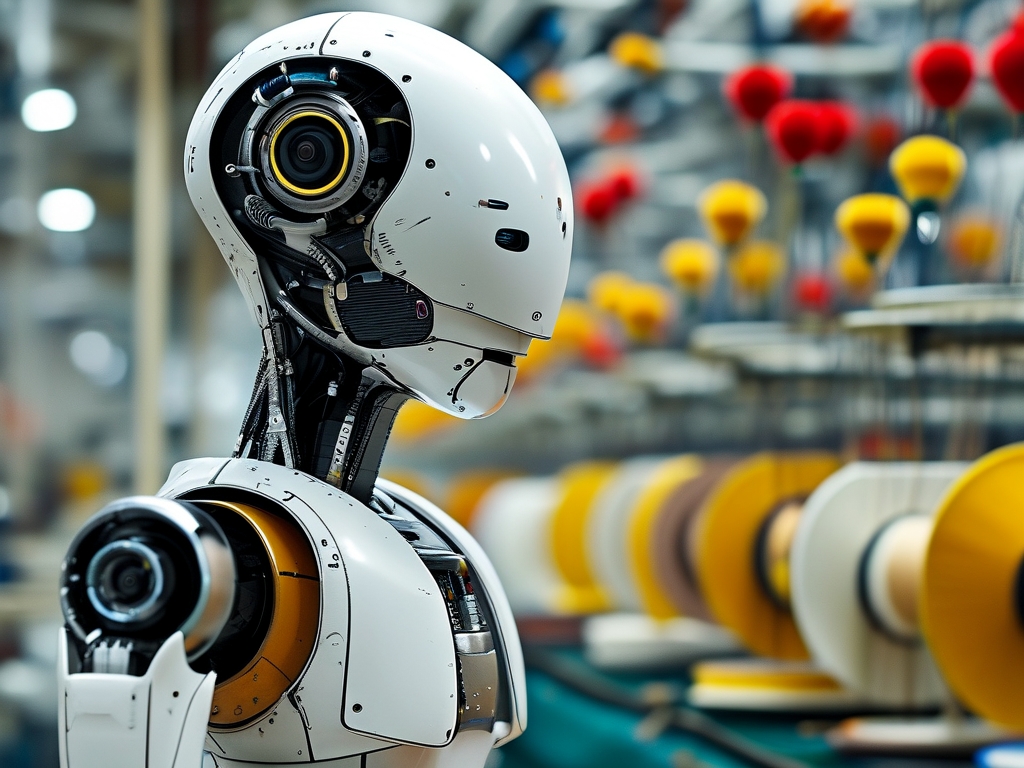

The textile industry, one of humanity's oldest crafts, is undergoing a seismic shift driven by robotics and automation. Robotic textile technology merges advanced mechanics, artificial intelligence (AI), and material science to redefine how fabrics are designed, produced, and customized. This article explores the core principles behind this innovation, its applications, and its implications for the future of manufacturing.

1. Core Components of Robotic Textile Systems

Robotic textile systems rely on three foundational elements: precision mechanics, sensor-based feedback, and AI-driven design.

- Precision Mechanics: Industrial robotic arms, equipped with specialized end-effectors (e.g., grippers, needles, or looms), execute tasks like weaving, knitting, or cutting with sub-millimeter accuracy. These robots mimic human hand movements but with enhanced speed and consistency. For example, multi-axis robotic arms can interlace threads in complex patterns unachievable by traditional looms.

- Sensor Integration: Force sensors, vision systems, and thermal detectors enable real-time adjustments. A robot weaving a 3D fabric structure, for instance, uses force feedback to maintain tension and avoid yarn breakage. Computer vision ensures pattern alignment, even when handling delicate or irregular materials like carbon fiber composites.

- AI and Machine Learning: Algorithms analyze vast datasets-from historical textile designs to real-time production metrics-to optimize workflows. Generative design tools create novel fabric patterns, while predictive maintenance systems reduce downtime by anticipating mechanical failures.

2. Key Technologies Powering Robotic Textiles

a. Additive Manufacturing in Textiles

3D knitting machines, such as those developed by companies like Knitwear Labs, build garments layer by layer without seams. These robots use thermoplastic yarns melted and fused during production, enabling seamless, customizable clothing. This method reduces waste by 30–40% compared to cut-and-sew processes.

b. Collaborative Robotics (Cobots)

Cobots work alongside humans in hybrid production lines. For example, in luxury textile manufacturing, cobots handle repetitive tasks like embroidery, while artisans focus on intricate detailing. Sensors ensure safety, stopping movements if a human enters a predefined zone.

c. Smart Material Integration

Robotic systems now integrate "smart" materials, such as shape-memory polymers or conductive threads. A robot might weave a fabric embedded with sensors to monitor vital signs, creating wearable health-tech garments.

3. Applications Across Industries

- Fashion and Apparel: Brands like Adidas use robotic knitting for mass-customized sneakers, where each shoe adapts to a customer's foot shape.

- Medical Textiles: Robots produce antimicrobial wound dressings or compression garments with gradient pressure zones, tailored to patient anatomy.

- Aerospace and Automotive: Lightweight, high-strength fabrics for car interiors or aircraft components are woven with precision, reducing weight and improving fuel efficiency.

4. Advantages Over Traditional Methods

- Speed and Scalability: A robotic loom can produce 10x faster than manual labor, critical for meeting fast-fashion demands.

- Sustainability: Precision reduces material waste, while energy-efficient robots lower carbon footprints.

- Customization: AI algorithms enable on-demand production of bespoke designs, from personalized patterns to size-adjusted garments.

5. Challenges and Limitations

Despite its potential, robotic textile technology faces hurdles:

- High Initial Costs: Advanced systems require significant investment in hardware and software.

- Material Limitations: Not all fabrics (e.g., highly elastic or delicate silks) are compatible with current robotic handlers.

- Workforce Adaptation: Traditional textile workers need retraining to operate and maintain robotic systems, posing socioeconomic challenges.

6. The Future of Robotic Textiles

Emerging trends include biohybrid robots using microbial cellulose to "grow" fabrics and quantum computing-enhanced design tools for ultra-complex patterns. As AI becomes more intuitive, robots may autonomously collaborate across global supply chains, from raw material processing to retail delivery.

In , robotic textile technology is not merely automating an ancient craft-it is reimagining it. By merging precision, intelligence, and creativity, this innovation promises a future where fabrics are smarter, production greener, and customization accessible to all.