The rapid advancement of robotic palletizing technology has revolutionized industrial automation, reshaping manufacturing, logistics, and supply chain operations worldwide. From basic mechanical arms to AI-driven systems, the journey of robotic palletizing reflects a broader narrative of innovation, efficiency, and adaptability. This article explores the development of this technology, its current applications, and its future potential.

Historical Development of Robotic Palletizing

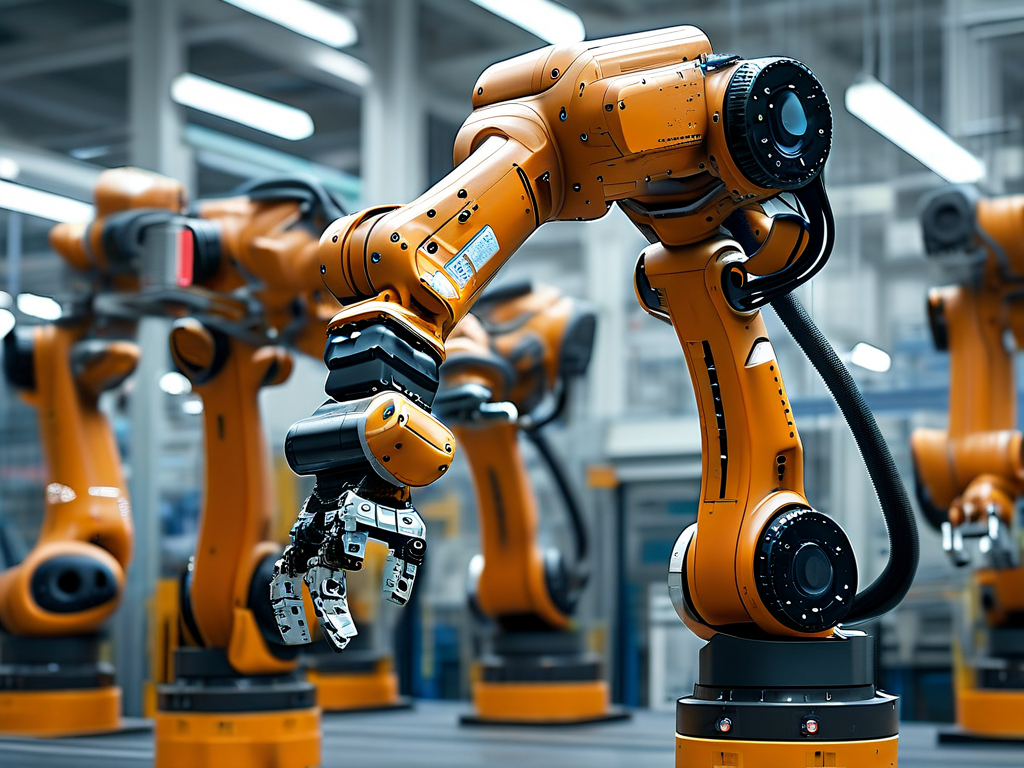

The origins of robotic palletizing date back to the 1960s, when the first industrial robots were introduced for repetitive tasks. Early systems were rudimentary, relying on fixed programming and limited flexibility. These machines could handle uniform objects in controlled environments but struggled with variability in size, weight, or packaging. By the 1980s, advancements in servo motors and programmable logic controllers (PLCs) enabled more precise movements, allowing robots to stack boxes and pallets with greater accuracy.

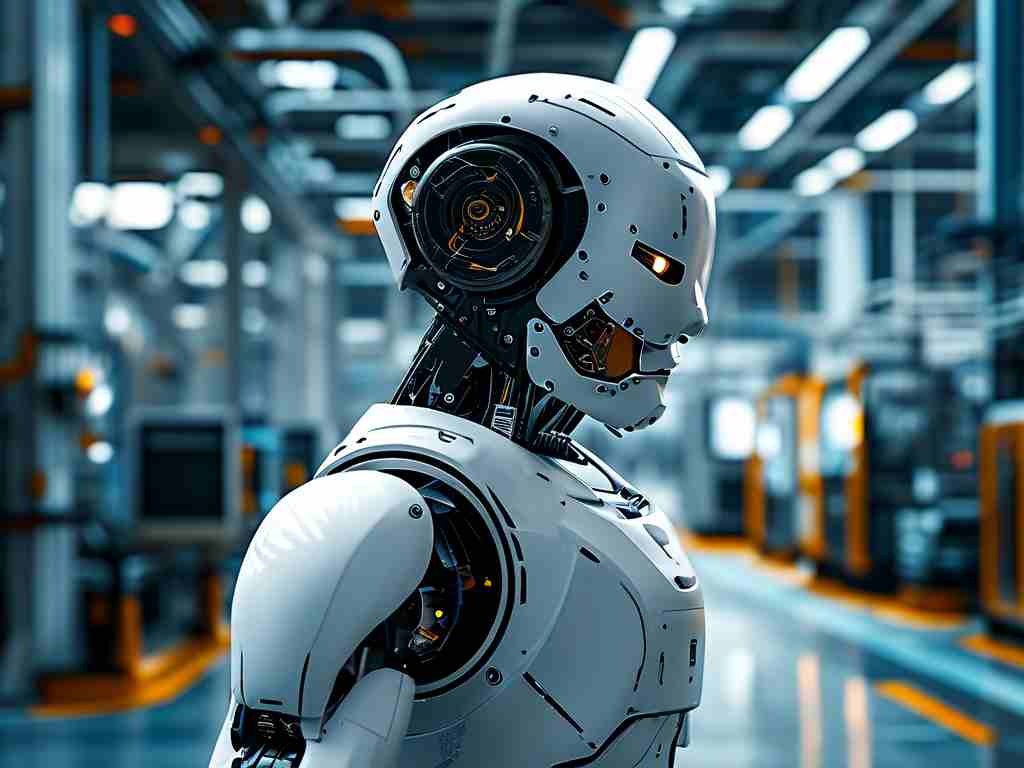

The 2000s marked a turning point with the integration of vision systems and sensors. Cameras and laser scanners allowed robots to "see" and adapt to irregularly shaped items, reducing dependency on pre-defined patterns. Collaborative robots (cobots) emerged in the 2010s, designed to work alongside humans safely, further expanding palletizing applications in small and medium-sized enterprises.

Key Technological Breakthroughs

- Advanced Grippers and End-Effectors: Modern palletizing robots use adaptive grippers, vacuum systems, and magnetic tools to handle diverse materials, from fragile glass bottles to heavy metal parts.

- AI and Machine Learning: Artificial intelligence enables predictive maintenance and real-time optimization. Machine learning algorithms analyze stacking patterns to minimize waste and maximize stability.

- Integration with IoT: Internet of Things (IoT) connectivity allows robots to communicate with warehouse management systems, adjusting workflows based on inventory levels or shipping deadlines.

- 3D Vision Systems: High-resolution 3D cameras provide depth perception, enabling robots to identify overlapping items or mixed pallet configurations.

Applications Across Industries

Robotic palletizing is no longer confined to automotive or electronics manufacturing. Its versatility now spans:

- Food and Beverage: Robots stack perishable goods like cartons of eggs or beverage crates without damage, adhering to strict hygiene standards.

- Pharmaceuticals: Precision palletizing ensures compliance with regulatory requirements for delicate medical supplies.

- E-commerce: High-speed systems process thousands of packages daily, meeting the demands of same-day delivery services.

A case study from a German logistics company revealed a 40% increase in throughput after deploying AI-powered palletizing robots, alongside a 30% reduction in product damage.

Challenges and Solutions

Despite its benefits, robotic palletizing faces hurdles:

- High Initial Costs: Small businesses often find the investment prohibitive. Modular, scalable systems are now being marketed to address this issue.

- Complex Environments: Unstructured settings (e.g., uneven floors or mixed-item pallets) require advanced algorithms. Hybrid systems combining robotics and human oversight are gaining traction.

- Maintenance Expertise: Cloud-based diagnostics and remote troubleshooting tools help operators manage technical issues without onsite specialists.

Future Trends

- Autonomous Mobile Palletizers: Mobile robots equipped with palletizing arms could navigate warehouses independently, merging transportation and stacking tasks.

- Sustainability Focus: Energy-efficient designs and recyclable packaging optimization algorithms will align with global green initiatives.

- Human-Robot Collaboration: Future systems may use augmented reality (AR) interfaces to let workers guide robots in real time for complex tasks.

Robotic palletizing technology has evolved from a niche automation tool to a cornerstone of modern industrial efficiency. As AI, IoT, and sustainable practices continue to drive innovation, these systems will become more accessible, intelligent, and integral to global supply chains. Companies that embrace this technology today are poised to lead tomorrow’s automated, data-driven economy.