The fusion of robotics and textile manufacturing has revolutionized the apparel industry, enabling faster production, precision, and customization. Robotic garment manufacturing technology combines advanced automation, artificial intelligence (AI), and material science to redefine how clothing is designed and produced. This article explores the core principles behind robotic garment manufacturing, its operational framework, and its transformative impact on the fashion and textile sectors.

Core Principles of Robotic Garment Manufacturing

-

Digital Design Integration

At the heart of robotic garment production lies digital design. Using computer-aided design (CAD) software, designers create 3D models of garments, specifying patterns, seams, and material properties. These digital blueprints are then translated into machine-readable instructions for robotic systems. Advanced algorithms optimize fabric usage and minimize waste by calculating the most efficient cutting paths.

-

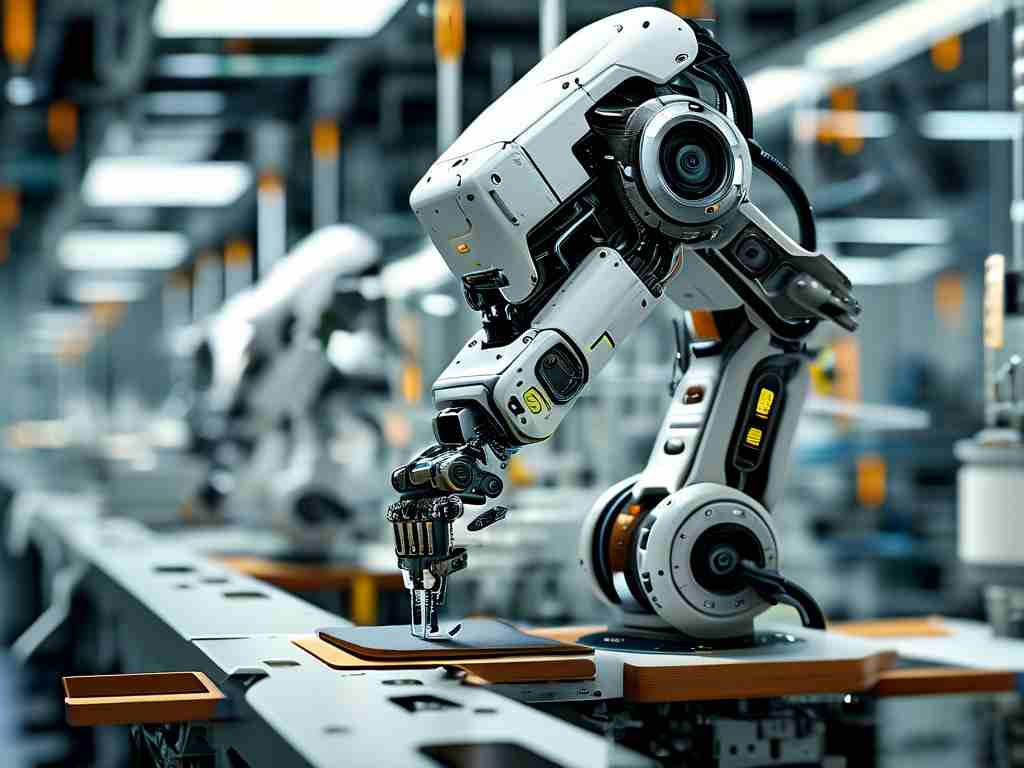

Automated Fabric Handling

Robotic arms equipped with vacuum grippers or adhesive systems handle fabrics with millimeter precision. Unlike traditional methods, robots can manipulate delicate or stretchable materials without distortion. Sensors embedded in the machinery detect fabric thickness, texture, and elasticity, adjusting grip strength and movement speed accordingly. -

Laser Cutting and Sewing

High-precision laser cutters replace manual scissors, enabling complex shapes and intricate patterns to be cut in seconds. For sewing, robotic sewing machines use computer vision to align fabric layers and execute stitches with sub-millimeter accuracy. Some systems employ multi-needle setups or ultrasonic welding for seamless joins, reducing reliance on human intervention.

-

AI-Driven Quality Control

Machine learning algorithms analyze real-time data from cameras and sensors to detect defects such as uneven stitches or fabric irregularities. Defective items are automatically flagged for reprocessing, ensuring consistent output quality. This self-correcting mechanism reduces waste and enhances production efficiency.

Operational Workflow

The robotic garment manufacturing process follows a four-stage workflow:

- Stage 1: Digital Prototyping – Designers create virtual garments and simulate their fit using AI-powered avatars.

- Stage 2: Material Preparation – Robots sort, layer, and position fabrics based on CAD specifications.

- Stage 3: Assembly – Cutting, sewing, and embellishment are performed by coordinated robotic systems.

- Stage 4: Finishing – Automated ironing, labeling, and packaging prepare garments for distribution.

Applications and Advantages

-

Mass Customization

Robotic systems enable on-demand production, allowing brands to offer personalized sizing, colors, and designs without compromising speed. For example, companies like Uniqlo and Adidas use robotic knitting machines to create custom-fit shoes and apparel in hours. -

Sustainable Manufacturing

By optimizing material usage and reducing errors, robotic technology cuts fabric waste by up to 30%. Additionally, energy-efficient machines and recyclable material handling contribute to greener production cycles. -

Labor and Cost Efficiency

While initial setup costs are high, robots reduce long-term expenses by minimizing human labor and operational downtime. A single robotic sewing unit can replace 10–15 manual workers, significantly lowering labor costs in high-wage regions. -

Rapid Prototyping

Fashion designers leverage robotic systems to iterate designs rapidly. A physical prototype can be produced within hours, accelerating time-to-market for new collections.

Challenges and Limitations

Despite its benefits, robotic garment manufacturing faces hurdles:

- Material Limitations: Highly elastic or irregular fabrics (e.g., lace) still require human handling.

- High Initial Investment: Small manufacturers may struggle to afford robotic systems, which can cost millions of dollars.

- Technical Complexity: Integrating AI, robotics, and supply chain management demands specialized expertise.

Future Trends

- Collaborative Robots (Cobots): Smaller, adaptive robots will work alongside humans in hybrid production lines.

- 3D Knitting Technology: Machines like KnitSense are pioneering seamless 3D-knitted garments, eliminating cutting and sewing entirely.

- Blockchain Integration: Supply chain transparency will be enhanced by blockchain-tracked robotic production data.

Case Study: Zara’s Automated Factories

Zara’s flagship automated facility in Spain uses over 500 robotic units to produce 80,000 garments daily. The system integrates RFID tagging and AI analytics to restock popular items within 48 hours, exemplifying the scalability of robotic manufacturing.

Robotic garment manufacturing technology represents a paradigm shift in the apparel industry. By merging precision engineering with sustainable practices, it addresses modern demands for speed, customization, and eco-consciousness. As AI and material science advance, robots will likely dominate textile production, reshaping global supply chains and consumer experiences alike.