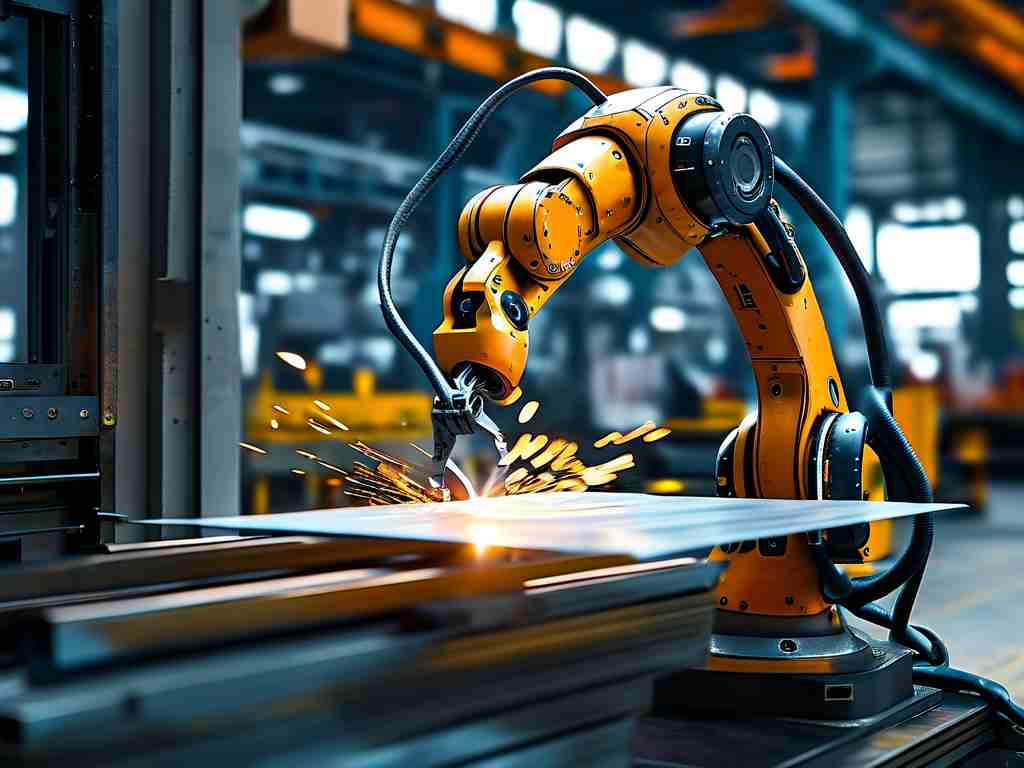

The rhythmic whir of servo motors and the precise clank of metal meeting die are becoming the soundtrack of modern manufacturing, particularly in sheet metal fabrication. At the heart of this transformation lies robotic bending technology, a sophisticated fusion of mechanics, programming, and sensor feedback. Understanding its core principles reveals why it's rapidly supplanting traditional press brakes for complex, high-volume, or highly repeatable tasks. This technology fundamentally revolves around automating the sheet metal bending process using programmable robotic arms equipped with specialized end-effectors, replacing manual operation on conventional press brakes.

The Core Hardware Ensemble

The principle starts with the robotic manipulator itself, typically a multi-axis articulated arm (often 6-axis for maximum dexterity). This provides the reach and flexibility to maneuver the metal sheet into position and interact with the bending tooling. The critical end-effector is the bending tool, commonly referred to as a "fingers" unit or a specialized gripper integrated with a bending mandrel. Unlike a press brake punch that moves vertically, the robot manipulates the sheet metal itself, pressing it against a fixed tool (the die) mounted on a sturdy table or beam. High-precision force/torque sensors are frequently integrated into the robot's wrist or the tooling interface. These sensors are paramount, providing real-time feedback on the interaction forces between the sheet, the die, and the robot's tool. This data is crucial for detecting contact, applying the correct bending force, and compensating for material variations or springback. Sophisticated grippers hold the sheet securely. They often feature adjustable fingers or specialized surfaces to accommodate different geometries and prevent marring the material surface. Some advanced systems might integrate tool changers, allowing a single robot to handle different bending tools or even perform secondary operations like handling or inspection.

The Guiding Intelligence: Software and Control

The principle of robotic bending hinges on sophisticated offline programming (OLP) and simulation software. Engineers create the bending sequence virtually within a digital twin environment that models the robot, the tooling, the sheet metal part, and the surrounding cell. The software calculates the precise robot paths, orientations, and the order of bends required to form the part without collisions. Crucially, it simulates the entire process, including how the sheet metal moves and deforms, identifying and resolving potential clashes between the robot, the part, the tooling, or fixtures before physical execution. This virtual validation is a cornerstone principle, minimizing costly downtime and scrap in production. Generating the optimal collision-free path for both the robot arm and the sheet metal throughout the entire bending sequence is a complex computational task. The software must account for the sheet's changing geometry after each bend and the physical constraints of the robot's reach and the tooling. Sophisticated algorithms determine the sequence of bends (bend planning) to minimize repositioning and ensure the final part can be formed without the tooling interfering with previously made bends. The control system translates the programmed paths into precise motor movements. Crucially, it continuously processes feedback from the force/torque sensors. If the measured force deviates from the expected value (indicating potential material thickness variation or slippage), the control system can make micro-adjustments to the robot's position or applied force in real-time to ensure bend accuracy. This closed-loop control is a key principle differentiating advanced robotic bending from simple automation. Furthermore, the system must accurately predict and compensate for springback – the inherent tendency of metal to elastically spring back slightly after the bending force is removed. Compensation algorithms, often based on material properties and bend angles derived from the CAD model and empirical data, are applied to the target bend angle during programming. The robot deliberately over-bends the material by a calculated amount so that it springs back to the desired final angle.

The Execution: A Dance of Precision

The operational principle unfolds in a coordinated sequence. The robot picks up the flat sheet metal blank, usually presented by a feeder system or another robot. Guided by its programmed path, the robot precisely positions the sheet so that the desired bend line is correctly aligned over the fixed die. The robot then maneuvers its bending tool (the fingers/mandrel) to press the sheet down onto the die. The force applied is carefully controlled based on sensor feedback and programmed parameters. The sheet plastically deforms around the die's radius, creating the bend. The robot may need to rotate or re-grip the sheet multiple times to present different edges to the die for subsequent bends, following the pre-optimized sequence. Throughout, the force sensors monitor the process, and the control system makes minute corrections. Once all bends are completed, the robot places the finished part onto an outfeed conveyor or pallet.

Advantages and the Driving Principle

The core principle driving the adoption of robotic bending is the pursuit of enhanced precision, repeatability, flexibility, and efficiency, especially for complex parts. Once programmed, a robot will execute the bends with micron-level repeatability, batch after batch, eliminating human variability. Robots can handle complex parts with multiple bends in different planes that would be challenging or impossible to produce efficiently on a manual press brake. Quick reprogramming allows rapid changeovers between different parts, ideal for high-mix, low-volume production. While the initial setup and programming require expertise, the actual bending cycle time can be faster than manual operation, especially for parts requiring multiple repositions. Furthermore, automation removes operators from potentially hazardous tasks involving heavy lifting and high-force machinery. Integration into larger automated cells (with laser cutting, welding, etc.) creates seamless production flows.

Code Snippet Illustrating Angle Calculation with Springback Compensation (Conceptual):

import numpy as np

def calculate_target_bend_angle(final_desired_angle, material_thickness, material_type, bend_radius):

"""

Calculates the target bend angle for the robot (including overbend for springback compensation).

This is a simplified conceptual example; real-world models are far more complex.

"""

# Lookup approximate springback factor (degrees) based on material and thickness (empirical data)

# This would typically come from a material database or calibration tests

springback_factor = get_springback_factor(material_type, material_thickness, bend_radius)

# Calculate the target angle the robot must achieve (overbend)

target_bend_angle = final_desired_angle + springback_factor

# Ensure the target is within safe/mechanical limits (e.g., 0-180 degrees)

target_bend_angle = np.clip(target_bend_angle, 1.0, 179.0)

return target_bend_angle

# Example usage (hypothetical values)

desired_angle = 90 # degrees

thickness = 2.0 # mm

material = "Stainless_Steel_304"

radius = 8.0 # mm

target_angle = calculate_target_bend_angle(desired_angle, thickness, material, radius)

print(f"Desired Final Angle: {desired_angle}°")

print(f"Robot Target Bend Angle (with compensation): {target_angle:.2f}°")

: The Evolving Principle

Robotic bending technology is not merely automation; it's an intelligent system built on principles of precise mechanics, advanced sensor feedback, sophisticated path planning, and adaptive control. The core principle involves the robot manipulating the sheet metal against a fixed die, guided by detailed offline programming and continuously adjusted by real-time sensor data to achieve highly accurate and repeatable bends, even compensating for material inconsistencies. As sensor technology, simulation software, and AI-driven path optimization continue to advance, the principles of robotic bending will evolve further, pushing the boundaries of complexity, speed, and autonomy in sheet metal fabrication. The integration of machine learning for predictive springback models and real-time quality assurance represents the next frontier in this transformative technology, solidifying its role as a cornerstone of smart manufacturing. Its ability to handle intricate geometries with unwavering consistency makes it indispensable for industries demanding high precision, from aerospace components to intricate electronics enclosures.