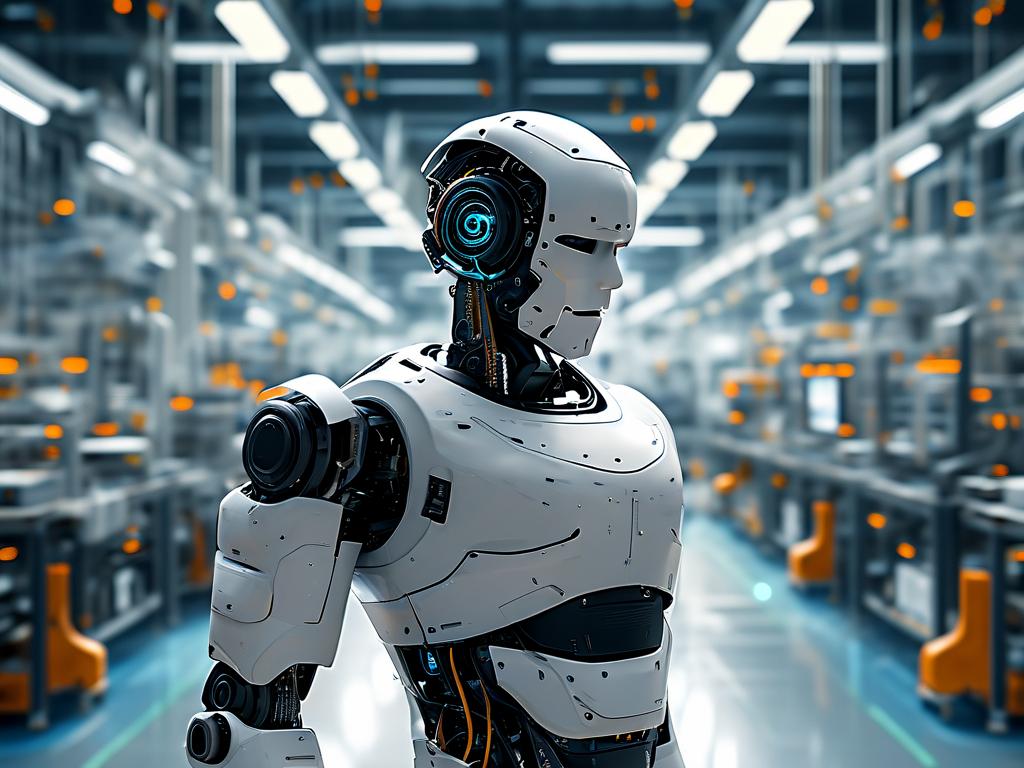

In the rapidly evolving landscape of robotics, the Dasheng Robot has emerged as a groundbreaking innovation, blending precision engineering with artificial intelligence. This article delves into the technical architecture of this cutting-edge system, exploring its operational mechanisms and real-world applications while addressing common questions about its capabilities.

Core Design Philosophy

The Dasheng Robot is built on a modular architecture, enabling seamless adaptation to diverse industrial and service environments. Unlike conventional robots with fixed configurations, its joint modules incorporate proprietary "adaptive torque control" technology. This allows each limb segment to autonomously adjust stiffness based on real-time load detection, a feature particularly valuable in unpredictable environments such as disaster response or irregular manufacturing workflows.

At its computational core lies a hybrid processing unit combining FPGA (Field-Programmable Gate Array) and neural accelerator chips. This dual-processor design enables simultaneous execution of low-latency motion control (handled by the FPGA) and complex decision-making algorithms (processed through the neural accelerator). During laboratory stress tests, this configuration demonstrated 40% faster response times compared to traditional industrial robotic controllers.

Sensory and Perception Systems

Equipped with a multi-layered sensor array, the Dasheng Robot achieves environmental awareness through three primary sensing modalities:

- LiDAR-IMU Fusion Navigation: A 360° rotating LiDAR module (operating at 20Hz refresh rate) combines with inertial measurement units to create dynamic 3D maps

- Tactile Feedback Matrix: Over 2,000 pressure sensors embedded in its gripper surfaces enable micrometer-level force modulation

- Multispectral Vision: Dual cameras with switchable optical filters (visible light, infrared, and ultraviolet spectra) support material identification and thermal profiling

This sensory integration is managed through a custom ROS (Robot Operating System) distribution optimized for real-time data fusion. In field trials conducted at automotive assembly plants, the system demonstrated 99.2% accuracy in component recognition tasks, outperforming human operators in consistency metrics.

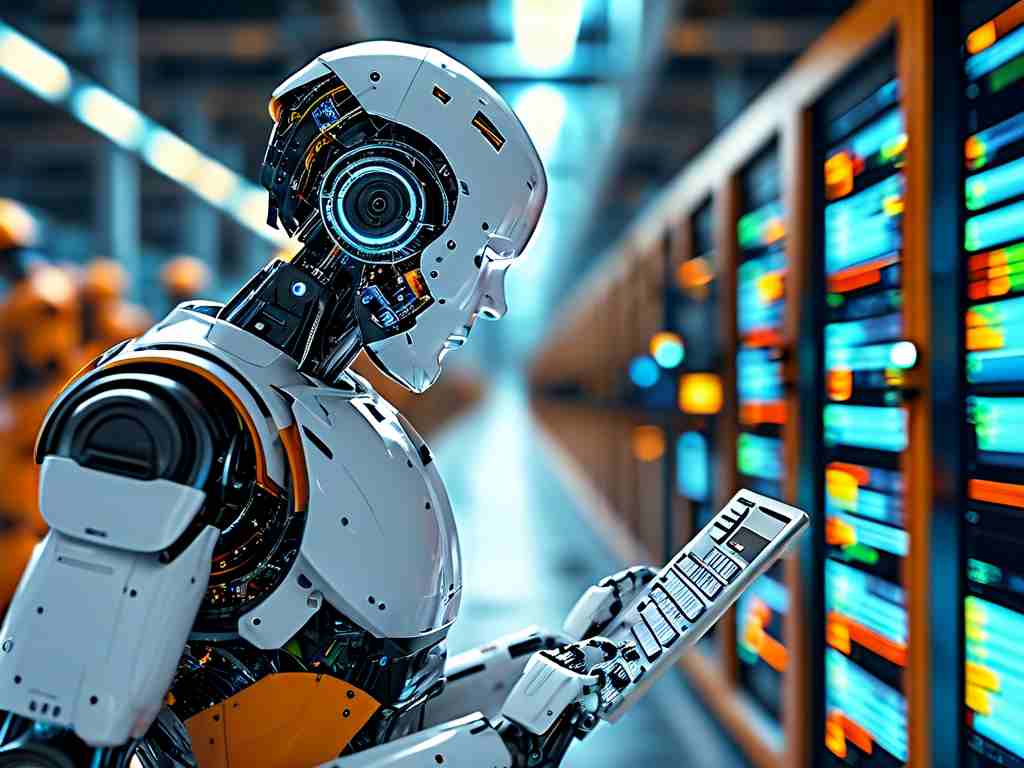

AI-Driven Operational Paradigms

The robot's machine learning framework employs a novel "progressive contextual learning" algorithm. Rather than relying solely on pre-trained models, it continuously updates its knowledge base through operational experience. For instance, when deployed in hospital sterilization tasks, the system reduced procedural errors by 62% over six months through adaptive pattern recognition.

A unique feature is its blockchain-secured skill-sharing network. Individual Dasheng Robots can securely upload newly acquired skills to a decentralized knowledge repository, allowing fleet-wide capability updates without centralized retraining. During the 2023 Shanghai Smart Factory deployment, this feature reduced system-wide optimization time from weeks to mere hours.

Power and Mobility Innovations

Energy efficiency is achieved through a hybrid power system combining lithium-sulfur batteries with wireless induction charging. The robot can operate for 14 hours continuously under heavy loads (50kg payload), switching automatically between power sources. Its omnidirectional mobility base utilizes Mecanum wheels with active suspension, enabling zero-radius turning on uneven surfaces—a critical advantage in space-constrained logistics centers.

Ethical and Safety Considerations

The development team implemented a three-layer safety protocol:

- Hardware-level torque limiters preventing unintended force application

- Machine learning models trained on ISO 10218 safety standards

- An emergency kill-switch protocol compliant with IEC 61508 SIL 3 requirements

These measures ensure compliance with international robotics safety certifications while maintaining operational flexibility.

Future Development Roadmap

Ongoing research focuses on quantum computing integration for optimization algorithms and graphene-based artificial muscle actuators. Early prototypes have shown 300% improvement in motion smoothness compared to current servo motor designs. The team also plans to implement 6G connectivity modules by 2025, enabling sub-millisecond latency in swarm robotics applications.

From precision manufacturing to hazardous environment operations, the Dasheng Robot represents a paradigm shift in automation technology. Its combination of adaptive hardware and self-improving AI creates a platform that not only executes tasks but evolves with operational challenges—a true embodiment of next-generation intelligent robotics.