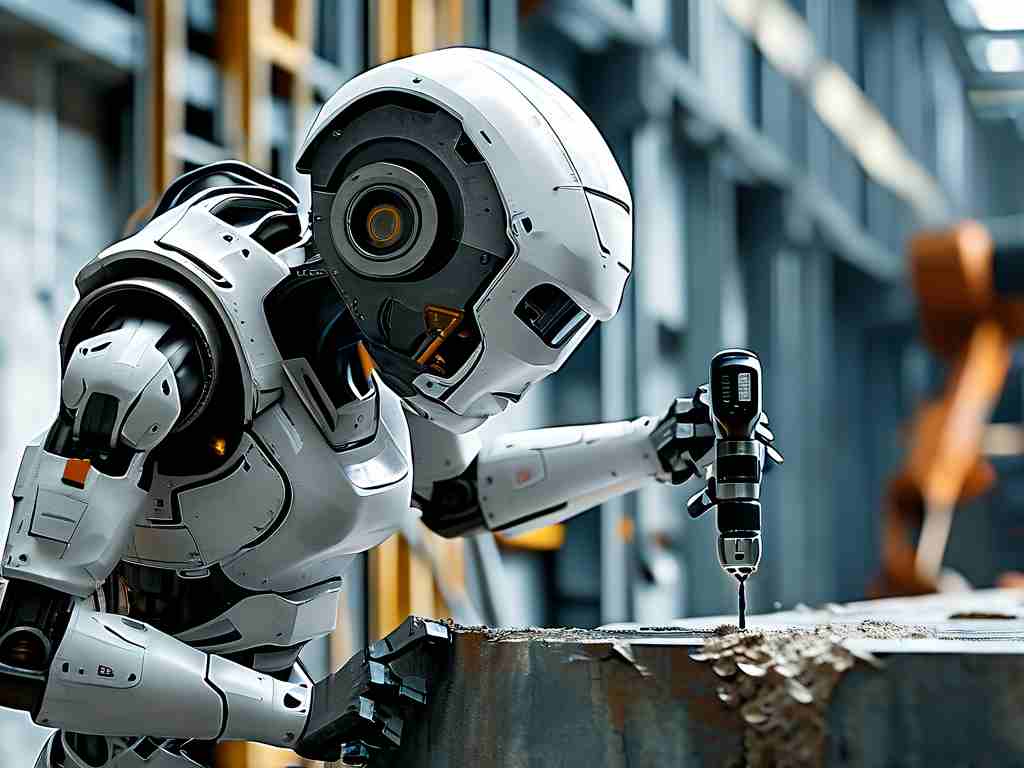

In modern construction and renovation industries, the advent of robot wall drilling technology has revolutionized how tasks like installing pipes, cables, or fixtures are performed. This innovation leverages automated systems to handle repetitive and precise drilling operations, reducing human error and enhancing safety. At its core, the principle involves robots equipped with advanced sensors and control mechanisms that mimic human actions but with superior accuracy and efficiency. This article delves into the underlying mechanisms, key components, and real-world applications of this technology, shedding light on its transformative impact.

The fundamental principle of robot wall drilling technology centers on three interconnected phases: positioning, drilling execution, and feedback control. First, the robot uses sensors such as laser scanners or computer vision cameras to map the wall surface. This allows it to detect obstacles like electrical wires or structural supports and calculate optimal drill points. For instance, a common setup involves LiDAR sensors that emit light pulses to measure distances and create a 3D model of the wall. This data is processed by onboard microcontrollers, ensuring the robot avoids hazards and aligns drills precisely based on predefined coordinates. Once positioned, the drilling phase kicks in, where high-torque motors drive diamond-tipped bits or rotary hammers through materials like concrete or drywall. These motors are often powered by electric or pneumatic systems, delivering consistent force without overheating. To illustrate, a typical code snippet for controlling the motor speed might look like this in a simplified Python simulation:

def control_drill_speed(sensor_data):

target_speed = 1500 # RPM for optimal drilling

current_speed = sensor_data.get('motor_rpm', 0)

if current_speed < target_speed:

increase_power() # Function to boost motor output

elif current_speed > target_speed:

decrease_power() # Reduce to prevent damage

return adjusted_speed

This code helps maintain steady drilling under varying wall densities, demonstrating how software integrates with hardware for real-time adjustments. Finally, the feedback control loop uses force sensors and accelerometers to monitor resistance and vibrations. If unexpected hardness or movement occurs, the robot automatically pauses or recalibrates, preventing damage to the wall or itself. This closed-loop system ensures each hole is drilled to exact specifications, such as depth and diameter, with minimal waste.

Beyond the core mechanics, several key technologies drive robot wall drilling systems. Artificial intelligence algorithms play a crucial role, enabling predictive maintenance by analyzing historical data to foresee component failures. For example, machine learning models can predict when drill bits need replacement based on wear patterns, reducing downtime. Additionally, wireless connectivity allows these robots to sync with building information modeling (BIM) software, where digital blueprints guide drilling paths without manual input. Energy efficiency is another highlight, as many units incorporate regenerative braking in motors to recycle kinetic energy, cutting power consumption by up to 30% compared to traditional methods. Safety features are paramount too, with emergency stop protocols and collision-avoidance systems using ultrasonic sensors to halt operations if humans approach the work zone. Such innovations make these robots ideal for hazardous environments like demolition sites or high-rise buildings.

The applications of robot wall drilling technology span diverse sectors, offering substantial benefits. In residential construction, these robots speed up tasks like mounting shelves or running utilities, slashing project timelines by half while improving precision. Commercial settings, such as office fit-outs, see cost savings from reduced labor and material waste, as robots drill only where needed based on digital plans. Industrial maintenance also benefits, with robots accessing confined spaces to repair infrastructure without endangering workers. However, challenges persist, including high initial costs for advanced models and limitations in handling irregular surfaces like curved walls. Future trends point toward smarter integrations, such as swarm robotics where multiple units collaborate on large-scale projects, or enhanced AI for self-learning capabilities that adapt to new materials autonomously.

In , robot wall drilling technology represents a leap forward in automation, blending precise mechanics with intelligent controls to transform how walls are modified. By understanding its principles—from sensor-based positioning to adaptive drilling—industries can harness efficiency and safety gains. As research advances, expect broader adoption and innovations that push the boundaries of what robots can achieve in construction and beyond.