The evolution of robotic joint technology has redefined precision and flexibility in automation systems. At the core of modern robotics, joints act as dynamic connectors that enable complex movements while balancing power efficiency and structural integrity. This article examines the engineering principles behind robotic joints, their operational challenges, and emerging innovations reshaping industries from manufacturing to healthcare.

Kinematic Architectures and Actuation Methods

Robotic joints rely on kinematic designs tailored to specific applications. Serial kinematic chains, common in articulated arms, prioritize dexterity for tasks like welding or assembly. Parallel configurations, such as delta robots, emphasize speed and rigidity for pick-and-place operations. The choice of actuation systems further defines performance:

- Electric motors (e.g., brushless DC or harmonic drive systems) dominate precision-critical applications

- Hydraulic actuators deliver high torque for heavy machinery

- Pneumatic systems enable rapid movements in lightweight setups

Emerging technologies like shape-memory alloys and electroactive polymers are pushing boundaries in compact joint designs.

Sensory Integration and Control Dynamics

Modern joints incorporate multi-layered feedback systems. Encoders with micron-level resolution track positional accuracy, while torque sensors adapt to variable loads using strain gauge technology. Advanced control algorithms process this data in real time:

# Simplified PID control pseudocode for joint positioning target_angle = get_target_position() current_angle = read_encoder() error = target_angle - current_angle integral += error * dt derivative = (error - prev_error) / dt output = Kp*error + Ki*integral + Kd*derivative adjust_motor(output)

This sensory-control loop enables adaptive behaviors, such as collision detection and force-controlled manipulation.

Material Science Breakthroughs

Composite materials are solving traditional trade-offs between strength and mobility. Carbon-fiber-reinforced polymers reduce inertial loads in high-speed joints, while liquid crystal elastomers enable bio-inspired motion patterns. Researchers at MIT recently demonstrated a joint prototype using graphene-enhanced lubricants, achieving 40% friction reduction compared to conventional bearings.

Thermal Management Strategies

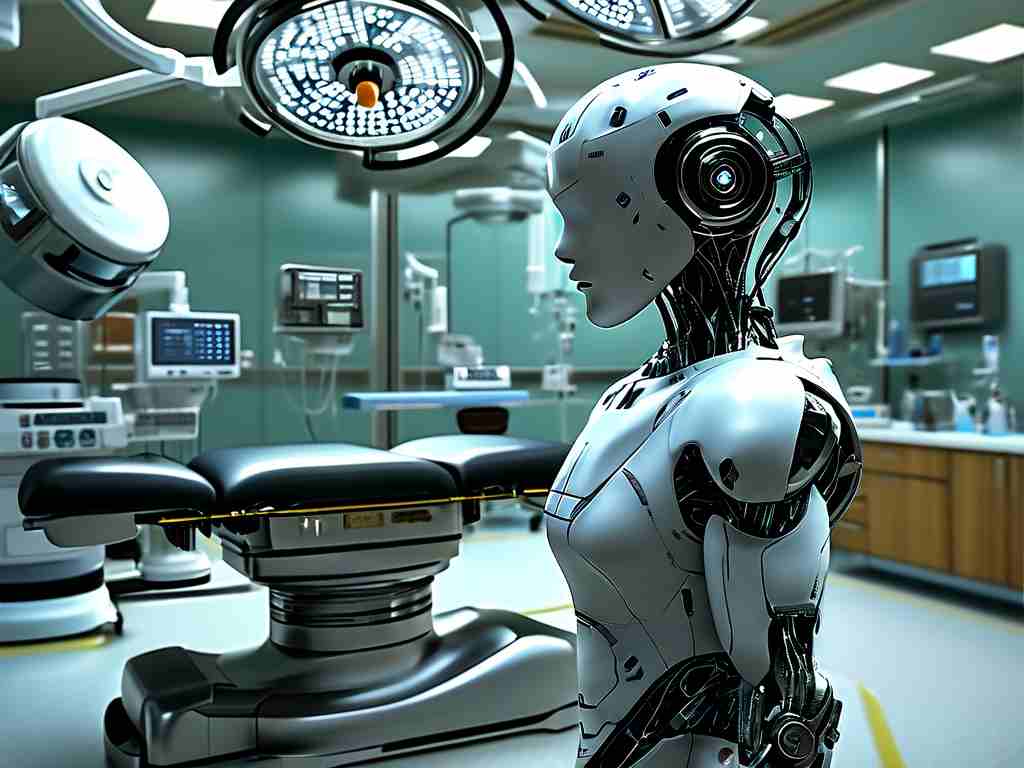

Power-dense joints face significant thermal challenges. Phase-change materials (PCMs) embedded in motor housings absorb heat during peak loads, while microchannel cooling systems circulate dielectric fluids in surgical robots requiring sterile environments. Toyota's latest humanoid robot implements variable thermal conductivity alloys that stiffen under heat to prevent positional drift.

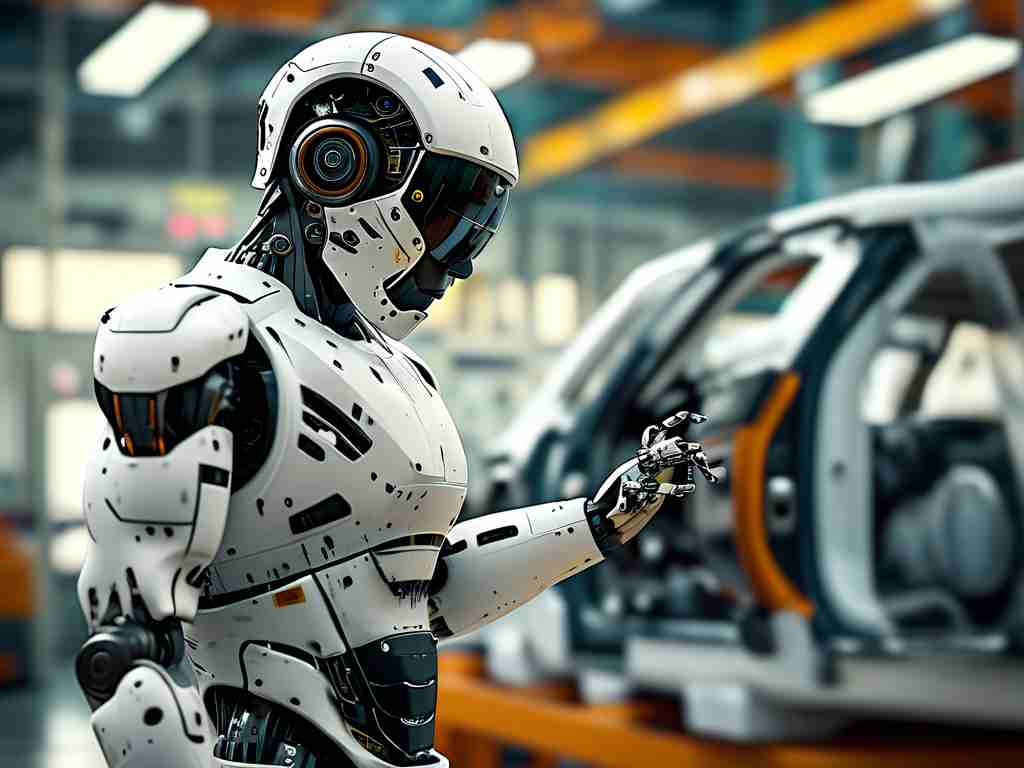

Industry-Specific Innovations

Medical robotics demands exceptional precision: The da Vinci surgical system's wristed instruments achieve 7 degrees of freedom through nested cable-driven joints. In contrast, agricultural robots like John Deere's See & Spray utilize prismatic joints with IP69K-rated seals for environmental resilience. Space robotics presents unique challenges—NASA's Robonaut 2 employs redundant harmonic drives capable of operating in -157°C to 121°C extremes.

Future Directions and Challenges

The integration of neuromorphic computing promises to revolutionize joint control. IBM's prototype using phase-change memory devices demonstrates 100x faster response in adaptive torque adjustments compared to traditional processors. However, power autonomy remains a hurdle—researchers are exploring piezoelectric energy harvesting from joint vibrations.

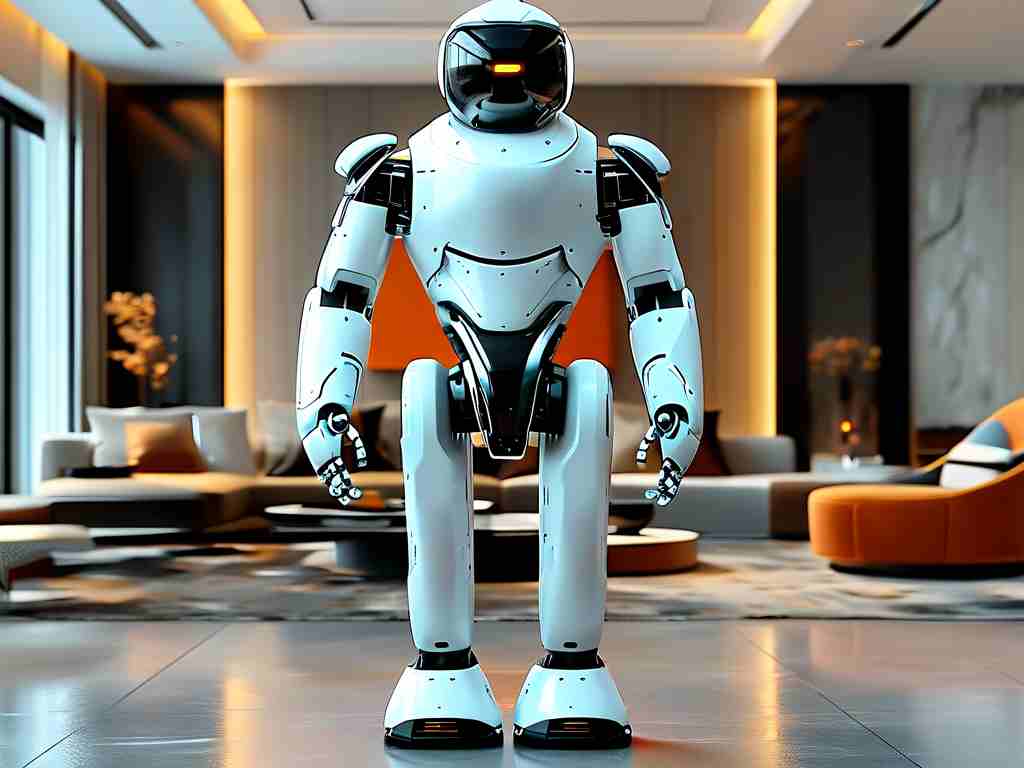

As collaborative robots (cobots) become ubiquitous, safety-focused joint designs are gaining prominence. Variable stiffness actuators using magnetorheological fluids can instantly transition between rigid and compliant states, enabling safe human interaction without sacrificing performance.

From nanoscale surgical tools to megawatt-class industrial manipulators, robotic joint technology continues to break barriers. The convergence of advanced materials, intelligent control systems, and bio-inspired designs suggests a future where robotic movement rivals biological efficiency and adaptability.