The evolution of robotic segmentation technology has revolutionized how machines perceive and interact with complex environments. By integrating advanced algorithms with hardware precision, this technology enables robots to identify, isolate, and process specific objects or regions within unstructured data. Its applications span industries from manufacturing to healthcare, making it a cornerstone of modern automation.

Core Principles of Robotic Segmentation

At its foundation, robotic segmentation relies on computer vision and machine learning. Computer vision systems capture visual data through sensors, while machine learning models—particularly convolutional neural networks (CNNs)—analyze spatial patterns. For instance, in industrial settings, robots use these systems to distinguish between defective and intact products on assembly lines. Unlike traditional methods that depend on pre-programmed thresholds, modern segmentation adapts dynamically by training on diverse datasets, improving accuracy in variable conditions.

A critical advancement is the integration of 3D depth sensing. By combining RGB cameras with LiDAR or structured light sensors, robots gain spatial awareness, allowing them to segment objects based on both color and geometry. This dual-layered analysis is vital for tasks like robotic surgery, where distinguishing between overlapping tissues requires millimeter-level precision.

Industry Applications

1. Healthcare and Surgical Robotics

In minimally invasive surgeries, segmentation technology guides robotic arms to differentiate between organs, blood vessels, and tumors. Platforms like the da Vinci Surgical System leverage real-time image segmentation to enhance a surgeon’s view, reducing procedural risks. Recent developments even enable autonomous suturing by identifying tissue boundaries without human intervention.

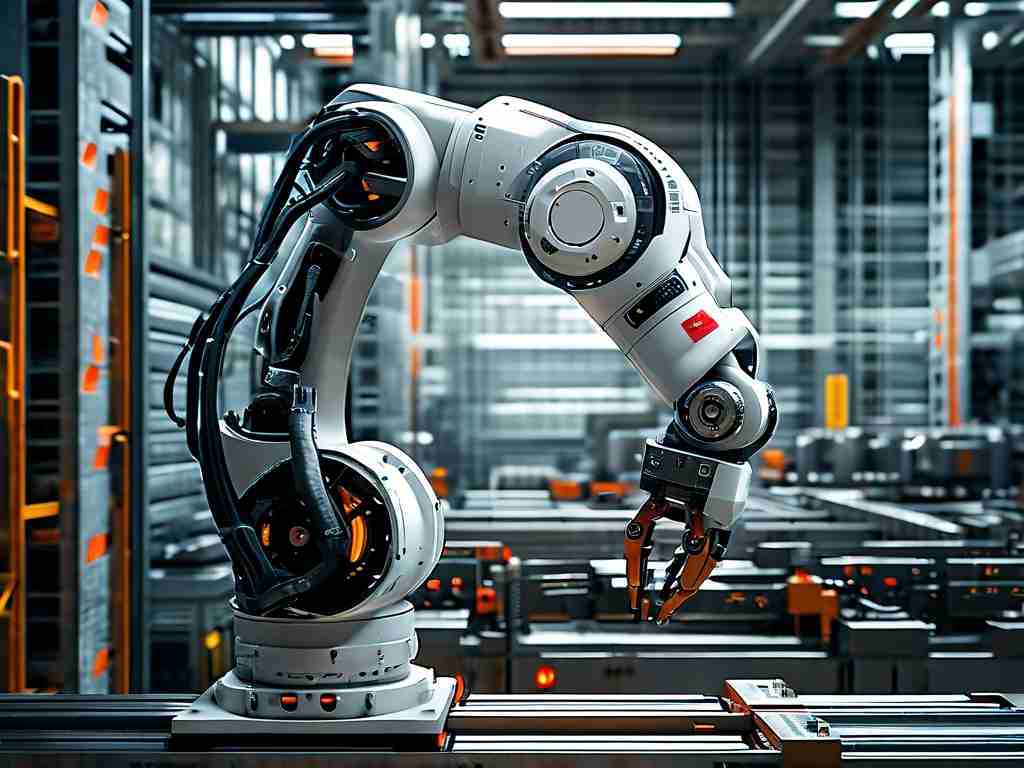

2. Manufacturing and Quality Control

Automated production lines deploy segmentation for defect detection. For example, automotive manufacturers use robotic systems to inspect welded joints. By comparing segmented images against CAD models, robots flag inconsistencies invisible to the human eye. This application cuts inspection time by 60% while boosting defect detection rates.

3. Agricultural Automation

Agribots equipped with multispectral cameras employ segmentation to monitor crop health. By isolating areas affected by pests or drought, these robots enable targeted pesticide or irrigation deployment. Startups like Blue River Technology have pioneered "see-and-spray" systems that reduce chemical usage by 90%, showcasing the environmental benefits of precise segmentation.

Technical Challenges and Solutions

Despite its potential, robotic segmentation faces hurdles. Variability in lighting, object shapes, and occlusions can degrade performance. Engineers address these through hybrid models that merge CNNs with classical algorithms like region-growing or edge detection. For example, combining U-Net architectures with morphological operations improves segmentation accuracy in low-light industrial environments.

Another challenge is computational latency. Real-time applications, such as autonomous vehicles, require split-second decisions. To optimize speed, developers deploy lightweight neural networks (e.g., MobileNet) and leverage edge computing. NVIDIA’s Jetson platform, for instance, processes 4K video feeds at 30 FPS, enabling drones to segment terrain features during flight.

Future Directions

Emerging trends focus on enhancing adaptability. Meta-learning frameworks allow robots to generalize across tasks with minimal retraining—a breakthrough for small-batch manufacturing. Meanwhile, neuromorphic computing mimics biological neural networks, promising energy-efficient segmentation for portable robots.

Ethical considerations also loom large. As segmentation enables robots to recognize human features, privacy concerns arise. Researchers advocate for federated learning systems, where models train on decentralized data to prevent misuse.

In , robotic segmentation technology bridges the gap between raw sensory input and actionable intelligence. Its continued refinement will unlock new frontiers in automation, from personalized medicine to sustainable agriculture. As algorithms grow more sophisticated and hardware more accessible, the line between human and machine perception will increasingly blur—ushering in an era of collaborative intelligence.