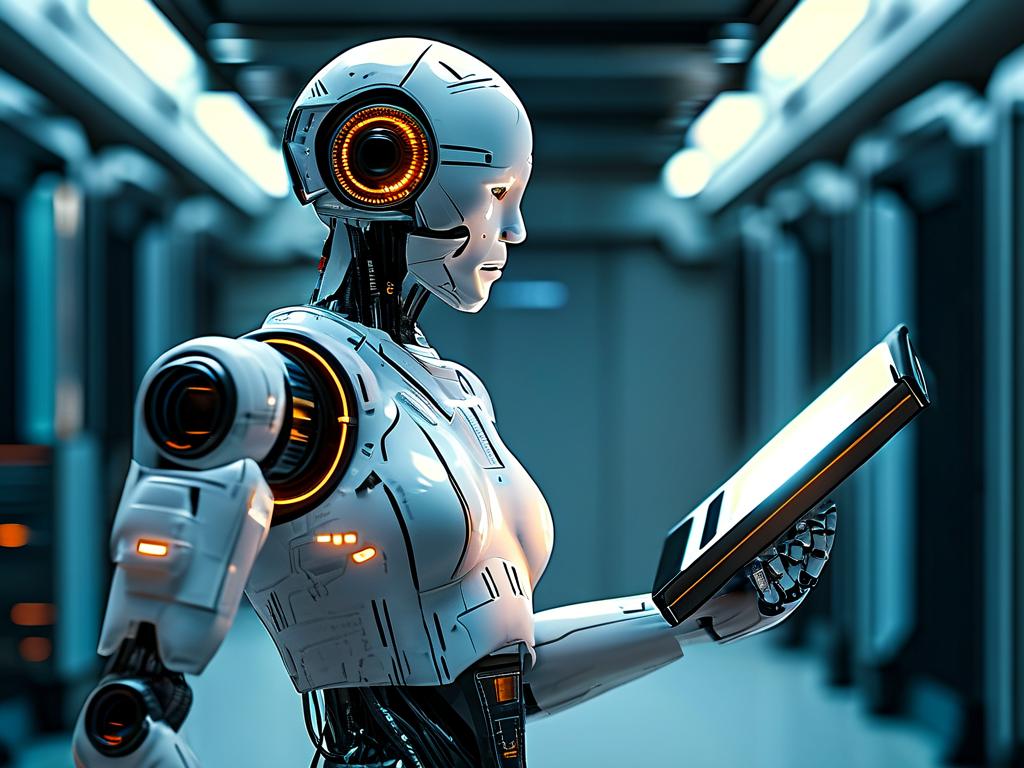

The integration of intelligent logistics robots has become a transformative force in global supply chain management. These autonomous systems, powered by artificial intelligence and advanced sensor networks, are redefining efficiency standards across warehousing, transportation, and inventory control operations. Unlike traditional automation solutions, modern logistics robots demonstrate unprecedented adaptability, capable of making real-time decisions in dynamic industrial environments.

At the core of this technological shift lies the fusion of machine learning algorithms with robotic hardware. Companies like Amazon have deployed over 500,000 drive units in fulfillment centers worldwide, achieving 40% faster order processing times. These mobile robots collaborate with human workers through sophisticated coordination systems, optimizing pick-and-place operations while reducing physical strain on staff.

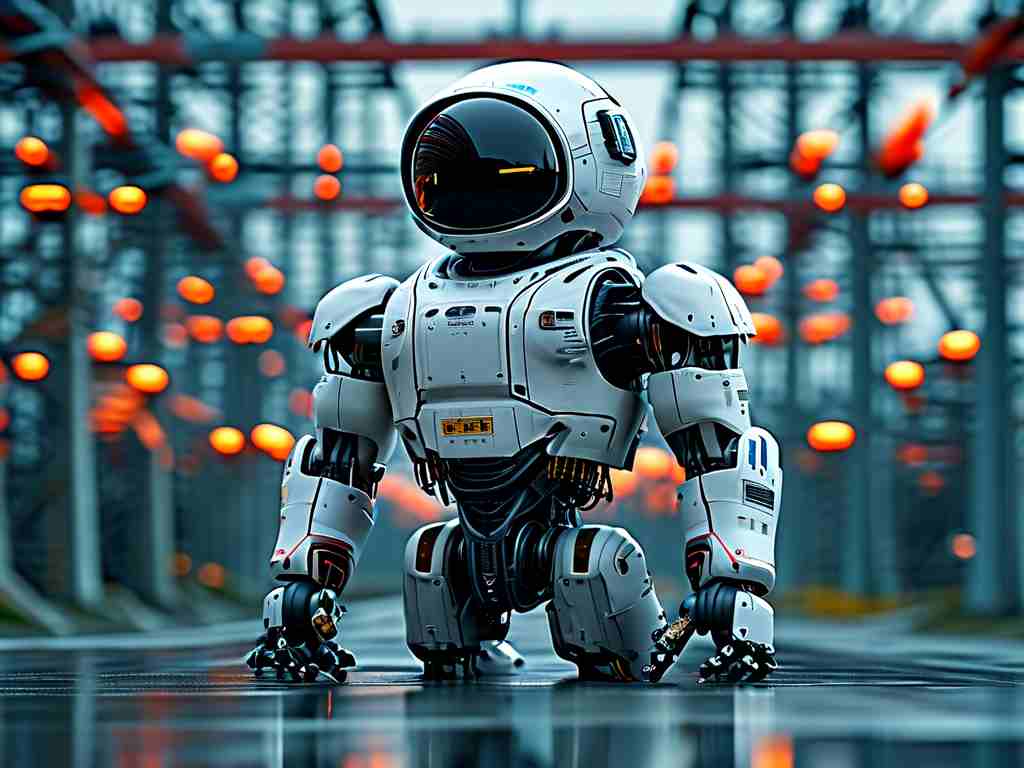

A critical advancement emerges in vision-guided navigation systems. New-generation logistics robots employ 3D spatial mapping and LiDAR technology to maneuver through crowded warehouses without predefined paths. This contrasts sharply with earlier automated guided vehicles (AGVs) that required magnetic tape or QR code markers. The DHL Smart Robotics program recently reported 99.8% navigation accuracy in pilot facilities, significantly minimizing product damage during intra-warehouse transfers.

The financial implications are equally compelling. Third-party logistics providers adopting robotic systems observe 25-35% reductions in operational costs within 18 months of implementation. This stems from multiple factors: 24/7 operational capability, minimized human error in inventory tracking, and predictive maintenance algorithms that reduce downtime. Notably, Chinese e-commerce giant JD.com achieved 90% automation in its Shanghai "Asia No.1" facility, processing over 1.6 million orders daily during peak seasons.

However, challenges persist in workforce adaptation. Successful deployments require hybrid operational models where robots handle repetitive tasks while humans manage exception handling and quality control. Companies like Ocado Technology have developed "cobotic" workstations where robotic arms and human operators share workspace through AI-mediated safety protocols. This approach maintains employment levels while boosting productivity – a UK automotive parts distributor reported 22% higher output per worker after cobotic system integration.

Looking ahead, 5G connectivity promises to unlock new capabilities. Ultra-low latency communication enables real-time swarm intelligence among robot fleets, allowing dynamic task redistribution during unexpected disruptions. Siemens recently demonstrated a prototype system where 50 robots autonomously reconfigured warehouse layouts in response to shifting inventory patterns, achieving 18% better space utilization.

Environmental sustainability represents another frontier. Solar-powered autonomous forklifts are reducing carbon footprints in logistics hubs, with German manufacturer STILL estimating 120 tons of CO2 reduction annually per 100 units deployed. Meanwhile, machine learning-driven route optimization in delivery robots has shown 15% fuel savings in last-mile operations across urban centers in Tokyo and San Francisco.

The regulatory landscape continues to evolve alongside these technological advancements. The European Union's revised Machinery Directive now includes specific provisions for mobile logistics robots, mandating enhanced collision avoidance systems and data security measures. Industry leaders anticipate similar regulatory developments in North America and Asia-Pacific markets within the next fiscal year.

As intelligent logistics robots become more accessible through Robotics-as-a-Service (RaaS) models, even mid-sized enterprises can leverage these technologies. Startups like Locus Robotics offer subscription-based solutions starting at $3,500/month, democratizing access to automation that was previously exclusive to corporate giants. This shift is projected to drive 300% growth in the logistics robotics market by 2028, according to recent McKinsey analysis.

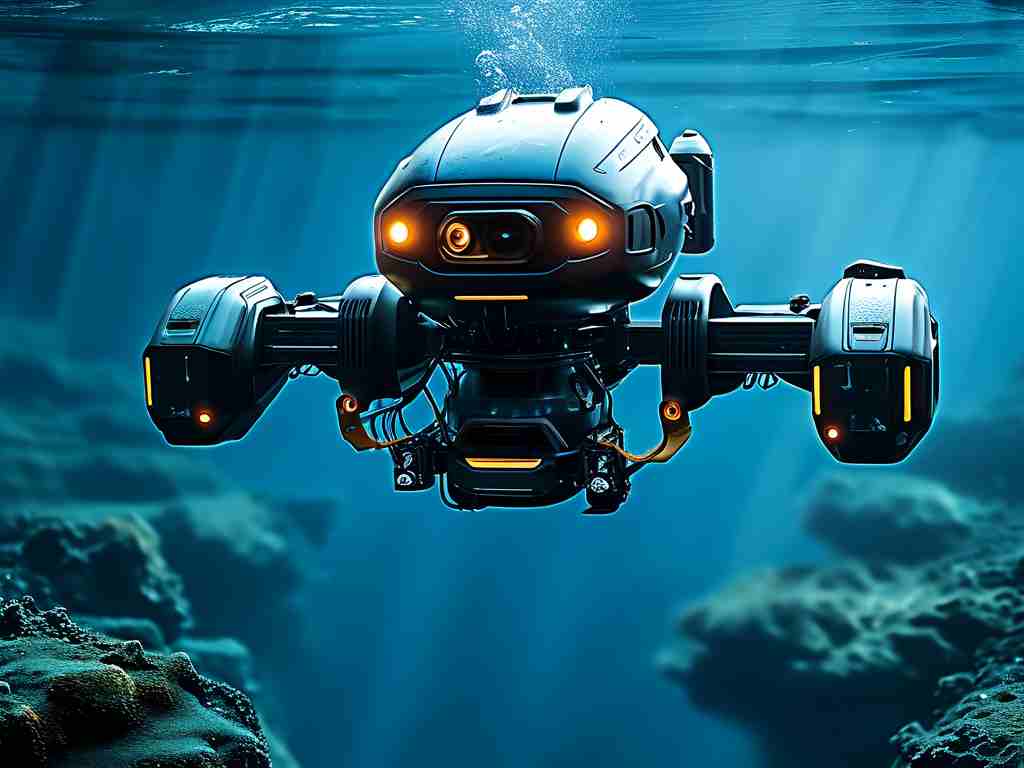

The ultimate impact extends beyond commercial efficiency. During the 2023 Türkiye earthquake relief efforts, AI-powered logistics drones delivered medical supplies to inaccessible areas within 45 minutes of request – a task that previously required 8-hour manual treks. Such humanitarian applications underscore the technology's potential to redefine global crisis response frameworks.

While concerns about job displacement persist, historical patterns suggest technological evolution creates more specialized roles than it eliminates. The World Economic Forum estimates 12 million new tech-driven logistics positions will emerge by 2030, focusing on robot maintenance, system optimization, and human-machine interface design. Educational institutions are already responding, with MIT launching its first Autonomous Logistics Systems certification program in Q3 2024.

In , intelligent logistics robots represent more than operational upgrades – they signify a fundamental restructuring of global commerce mechanics. As these systems mature through continued innovation in edge computing and adaptive AI, businesses that strategically implement robotic solutions will gain decisive competitive advantages in accuracy, scalability, and operational resilience. The future of logistics isn't merely automated; it's intelligently responsive to an ever-changing commercial landscape.