The fields of robotics engineering and robotics technology are often conflated, yet they represent distinct disciplines with unique objectives, skill sets, and professional trajectories. Understanding these differences is critical for students, professionals, and organizations navigating the rapidly evolving landscape of automation and intelligent systems.

Defining the Disciplines

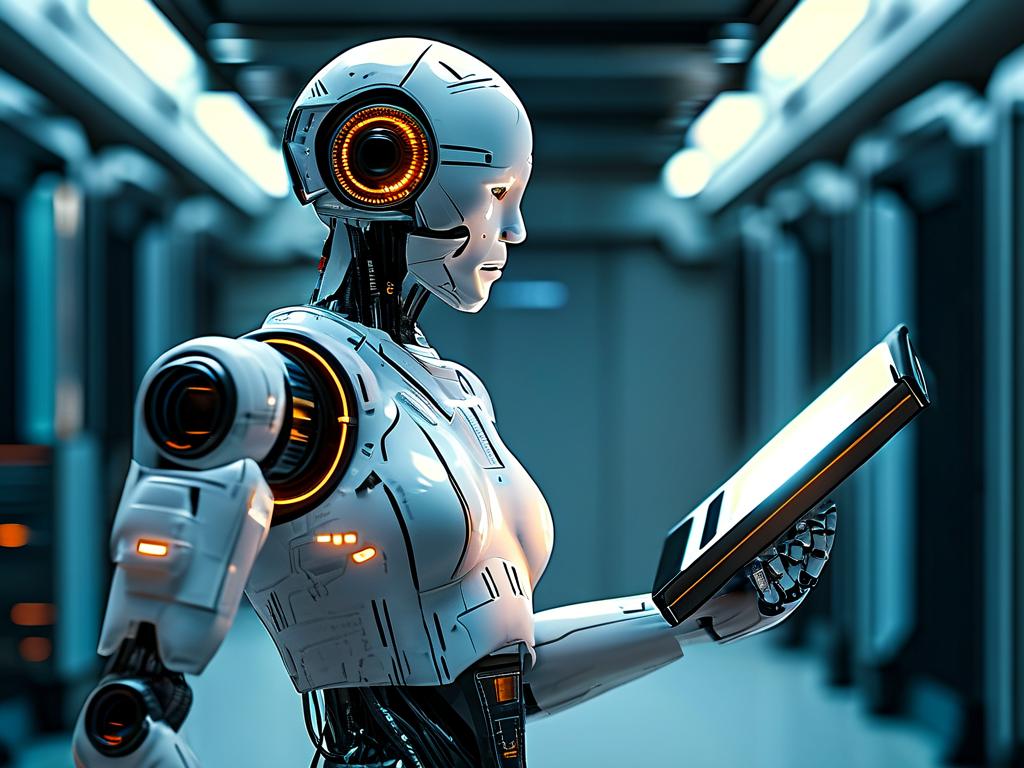

Robotics Engineering focuses on the design, development, and theoretical foundations of robotic systems. It combines principles from mechanical engineering, electrical engineering, and computer science to create hardware architectures, control algorithms, and sensory integration frameworks. Engineers in this field often work on innovations such as advanced actuators, novel mobility systems, or AI-driven decision-making modules.

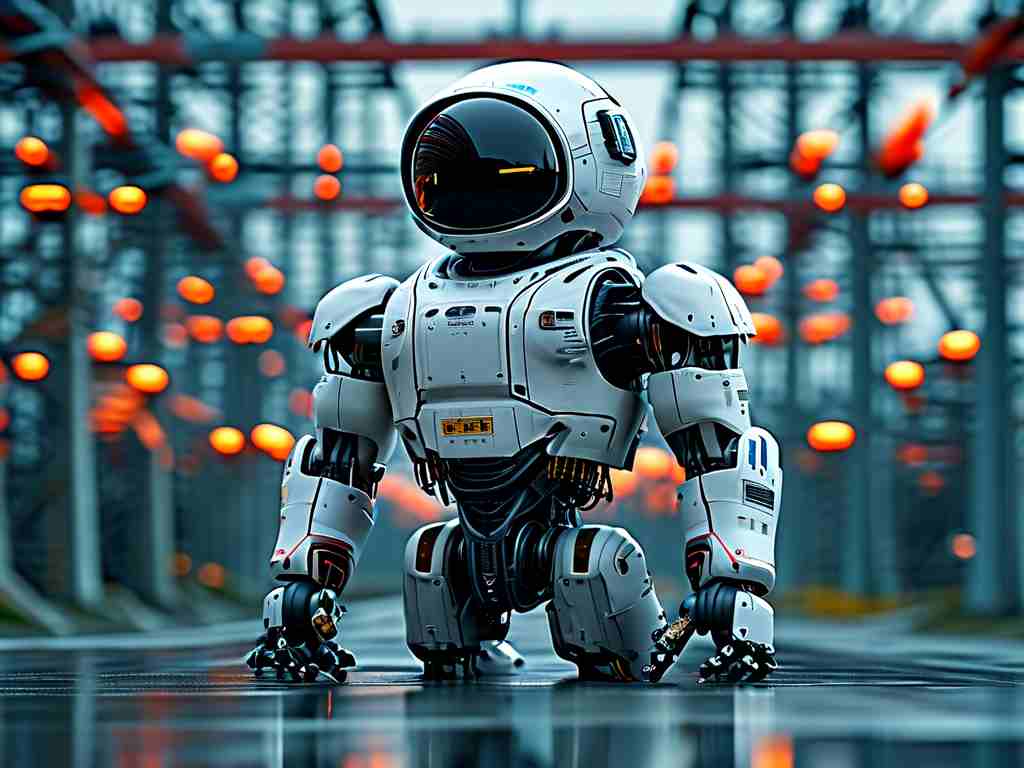

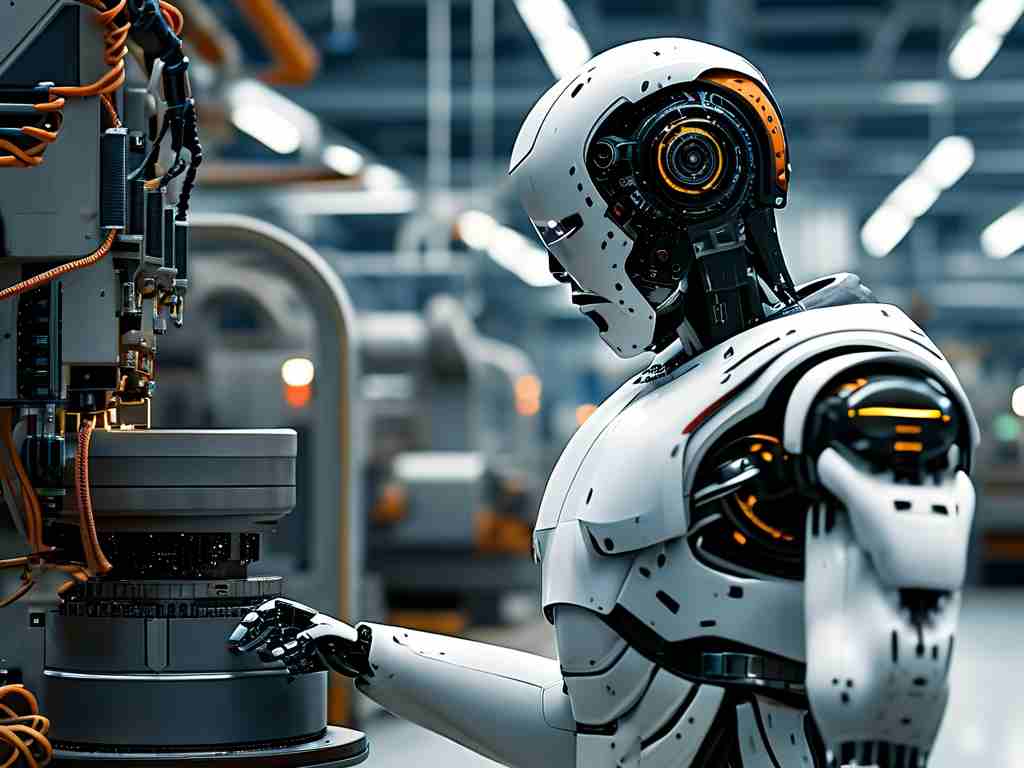

Robotics Technology, by contrast, emphasizes the practical implementation, maintenance, and optimization of existing robotic systems. Professionals in this domain specialize in deploying off-the-shelf robotic solutions, programming industrial arms, or troubleshooting automation workflows. Their work ensures seamless integration of robotics into manufacturing, healthcare, or logistics environments.

Core Focus Areas

A robotics engineer might spend months refining the kinematic model of a humanoid robot’s hand to achieve lifelike dexterity. This involves mathematical modeling, material science, and iterative prototyping. For example, Boston Dynamics’ Atlas robot required years of engineering research to balance dynamic motion with energy efficiency.

In robotics technology, a technician could configure a fleet of warehouse autonomous mobile robots (AMRs) to optimize inventory management. This task demands familiarity with sensor calibration, network communication protocols, and real-time monitoring tools. Companies like Amazon Robotics rely on such expertise to keep fulfillment centers operational.

Educational Pathways

Academic programs reflect this divergence. Robotics engineering degrees typically require advanced coursework in differential equations, control theory, and embedded systems design. Students might complete projects like building a quadcopter from scratch or developing machine vision algorithms for object recognition.

Robotics technology programs prioritize hands-on training in system integration, PLC programming, and industrial safety standards. Learners often earn certifications in platforms like Fanuc or Universal Robots, preparing them to operate collaborative robots (cobots) in automotive assembly lines or food processing plants.

Industry Applications

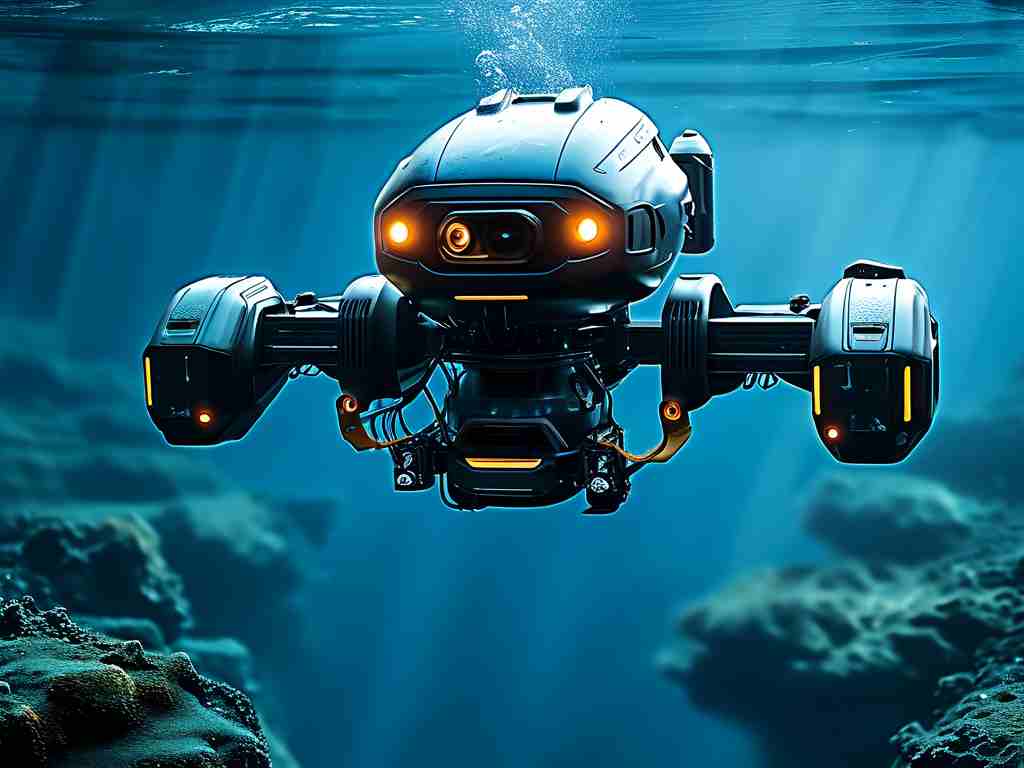

The engineering side drives breakthroughs in specialized domains. Surgical robots like the da Vinci System exemplify engineering rigor—integrating precision mechanics, haptic feedback, and sterile material compliance. Similarly, Mars rovers showcase engineered solutions for extreme environments through radiation-hardened components and autonomous navigation systems.

Technology specialists shine in scalable implementations. Agricultural drones mapping crop health or hotel service robots delivering amenities rely on technicians to adapt hardware/software interfaces for specific use cases. During the COVID-19 pandemic, UV-disinfection robots were rapidly deployed in hospitals—a feat achieved through technical adaptations rather than ground-up engineering.

Career Trajectories

Robotics engineers often gravitate toward R&D roles in aerospace, biomedical device firms, or AI startups. Their work frequently involves patent development, academic collaborations, and long-term innovation cycles. A senior engineer at Tesla Optimus might lead a team developing neural networks for human-robot interaction.

Robotics technologists thrive in operational roles—automation managers in factories, field service engineers for robotics OEMs, or integration consultants. Their value lies in minimizing downtime and maximizing ROI. For instance, a Bosch Rexroth technician might retrofit legacy manufacturing equipment with vision-guided robotic arms while training plant staff.

Synergy in Practice

These disciplines intersect in real-world projects. Consider an automated warehouse: engineers design the robotic picking arm’s mechanical structure and grasping algorithms, while technologists program the fleet management software and maintain the charging stations. Both roles are essential—the engineer ensures technical feasibility, while the technologist guarantees operational reliability.

As robotics permeates industries from construction to elder care, both fields will grow. Engineering will push boundaries in soft robotics or swarm intelligence, while technology roles will evolve alongside 5G-enabled edge computing and predictive maintenance AI. Professionals must choose paths aligning with their strengths—theoretical innovation versus applied problem-solving—but collaboration between both domains will define the next era of automation.