The automotive industry has undergone a transformative shift with the integration of embedded systems, making the development process more complex yet efficient. This article explores the vehicle embedded development workflow, supported by video tutorials, to provide a clear understanding of its stages, tools, and best practices.

Understanding Vehicle Embedded Development

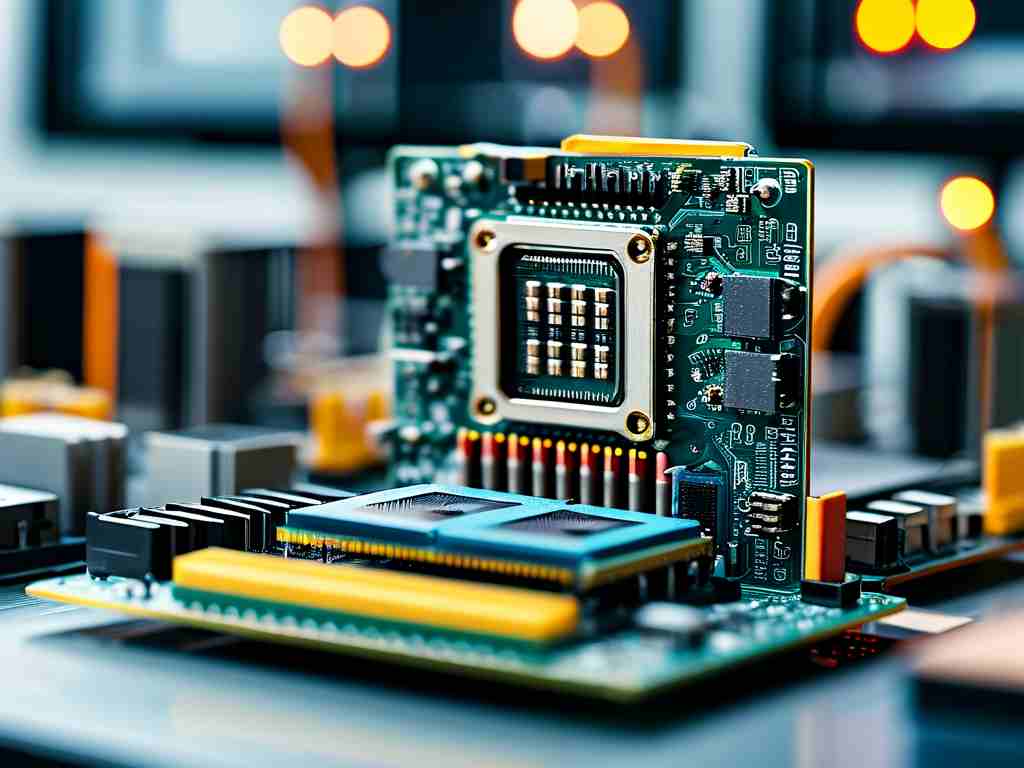

Embedded systems in vehicles are specialized computing platforms designed to control specific functions, such as engine management, infotainment, or advanced driver-assistance systems (ADAS). The development process involves hardware-software co-design, rigorous testing, and compliance with automotive safety standards like ISO 26262. Unlike traditional software projects, embedded vehicle systems demand real-time performance, low power consumption, and high reliability under extreme conditions.

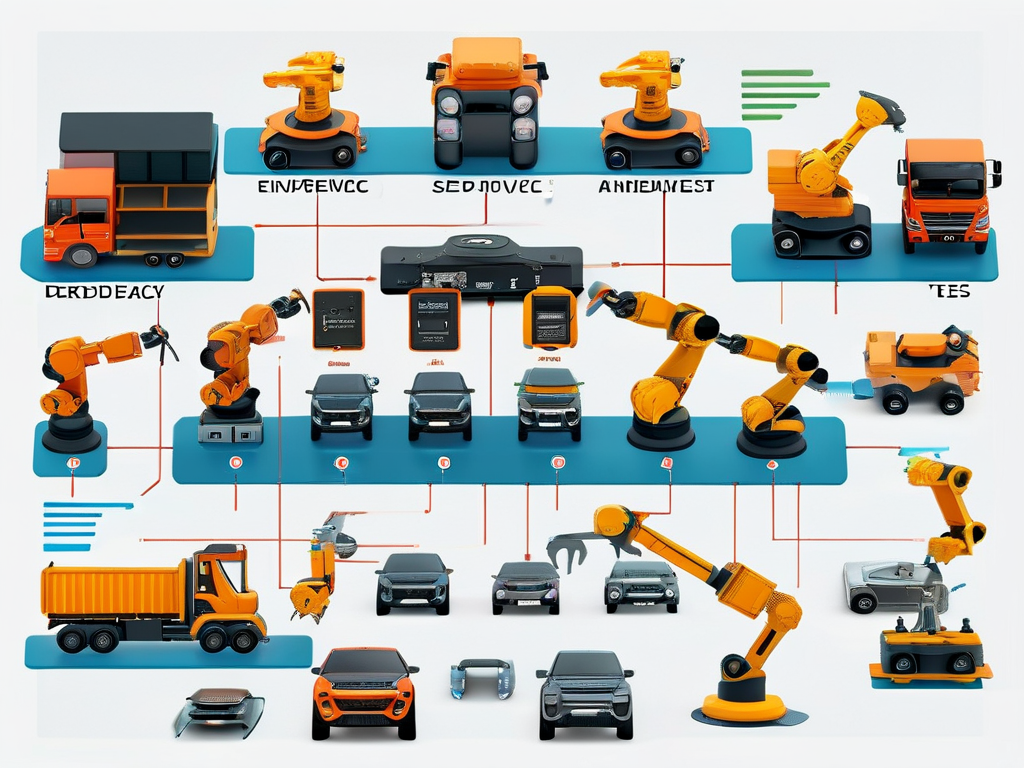

Key Stages in the Development Workflow

- Requirement Analysis: The process begins with gathering functional and non-functional requirements. For instance, a video tutorial might demonstrate how to document performance metrics for an electric vehicle's battery management system.

- System Architecture Design: Engineers create a blueprint that defines hardware components (e.g., microcontrollers, sensors) and software modules. Simulation tools like MATLAB/Simulink are often used to model interactions.

- Software Development: Developers write code in languages such as C or C++, adhering to the AUTOSAR standard for scalability. A video walkthrough could show how to implement CAN bus communication using a microcontroller.

- Hardware-Software Integration: This phase involves flashing firmware onto ECUs (Electronic Control Units) and validating interactions. Debugging tools like Lauterbach TRACE32 are critical here.

- Testing and Validation: Rigorous tests, including unit testing, HIL (Hardware-in-the-Loop), and field trials, ensure compliance with safety standards. Videos might highlight troubleshooting a sensor calibration error.

- Deployment and Maintenance: Post-deployment, over-the-air (OTA) updates are increasingly used to patch software remotely.

Role of Video Tutorials in Streamlining Workflows

Video tutorials serve as practical guides for engineers, especially for visual learners. For example, a step-by-step video on configuring an RTOS (Real-Time Operating System) for an ADAS module can reduce onboarding time for new team members. Additionally, video demos of tools like Vector CANoe or Wireshark for network analysis help bridge the gap between theoretical knowledge and hands-on application.

Challenges and Solutions

One major challenge is managing the interdependency between hardware and software. A video case study could illustrate how a team resolved timing conflicts in a hybrid vehicle's power distribution system. Another hurdle is ensuring cybersecurity, as connected vehicles are vulnerable to exploits. Tutorials on implementing secure boot mechanisms or encryption protocols can mitigate these risks.

Tools and Platforms

Popular tools include:

- Code Editors: Eclipse-based IDE for AUTOSAR projects.

- Simulators: QEMU for virtual hardware testing.

- Version Control: Git with platforms like GitHub or GitLab.

A video tutorial might compare the use of Keil MDK vs. IAR Embedded Workbench for ARM-based microcontrollers.

Future Trends

The rise of AI-driven embedded systems, such as autonomous driving modules, is pushing developers to adopt machine learning frameworks like TensorFlow Lite. Video resources on optimizing neural networks for low-power ECUs will become essential. Similarly, the shift toward electrification demands tutorials on developing battery management systems with predictive maintenance algorithms.

Mastering vehicle embedded development requires a blend of theoretical knowledge and hands-on practice. Video tutorials accelerate learning by providing visual, actionable insights into complex workflows. As the industry evolves, continuous learning through multimedia resources will remain pivotal for engineers aiming to innovate in this dynamic field.