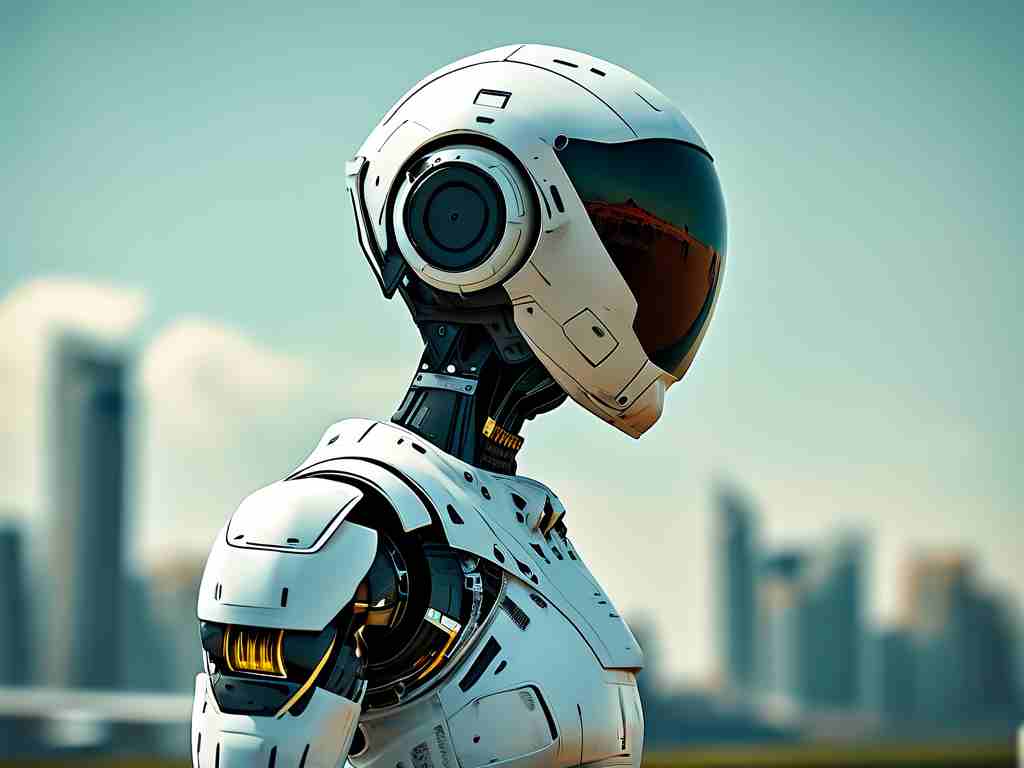

The integration of robotic spray painting technology into industrial workflows has revolutionized manufacturing, automotive, and aerospace industries. This article delves into the core principles, visual advancements, and real-world applications of this cutting-edge technology, supported by a collection of high-quality images that highlight its precision and versatility.

Precision and Efficiency in Automated Coating

Robotic spray painting systems leverage advanced algorithms and machine vision to achieve unparalleled accuracy. Unlike manual methods, robots can maintain consistent spray patterns, adjust parameters in real time, and operate in hazardous environments without compromising quality. For instance, automotive manufacturers rely on these systems to apply flawless paint coatings on vehicles, ensuring uniform thickness and minimizing material waste. High-resolution images of robotic arms in action reveal intricate details, such as the synchronization of nozzles and the seamless coverage of complex geometries.

Visualizing Innovation: Key Components and Workflows

A closer look at robotic spray painting setups showcases critical components like multi-axis arms, electrostatic applicators, and AI-powered sensors. These elements work in tandem to adapt to surface contours, detect defects, and optimize paint usage. In the furniture industry, for example, robots equipped with 3D scanning capabilities can customize finishes for irregularly shaped items, as seen in photos capturing their ability to coat curved wooden panels or metallic fixtures. Time-lapse sequences further illustrate how these systems reduce production cycles by up to 60% compared to traditional methods.

Safety and Sustainability Through Technology

Beyond efficiency, robotic spray painting enhances workplace safety by reducing human exposure to toxic fumes and repetitive tasks. Thermal imaging photos demonstrate how enclosed robotic cells contain overspray, while filtration systems capture harmful particles. Additionally, eco-friendly innovations like water-based paint compatibility and reduced VOC emissions align with global sustainability goals. Case studies from aerospace companies highlight how robots apply heat-resistant coatings to aircraft components, with before-and-after images underscoring the durability and aesthetic refinement achieved.

The Future: AI Integration and Customization

Emerging trends point to AI-driven systems that learn from historical data to predict maintenance needs or refine spray techniques. Hyperspectral imaging, for instance, enables robots to analyze surface textures and adjust coatings dynamically—a feature vividly depicted in side-by-side comparisons of manual versus robotic finishes. Meanwhile, collaborative robots (cobots) are entering smaller workshops, as shown in photos of compact setups where humans and machines work synergistically on custom projects like artistic murals or limited-edition product lines.

Robotic spray painting technology continues to evolve, blending technical prowess with visual elegance. From high-speed automotive lines to intricate art installations, the fusion of robotics and imaging tools unlocks new possibilities for industries worldwide. As the accompanying gallery of images reveals, this technology isn’t just about automation—it’s about redefining craftsmanship in the digital age.