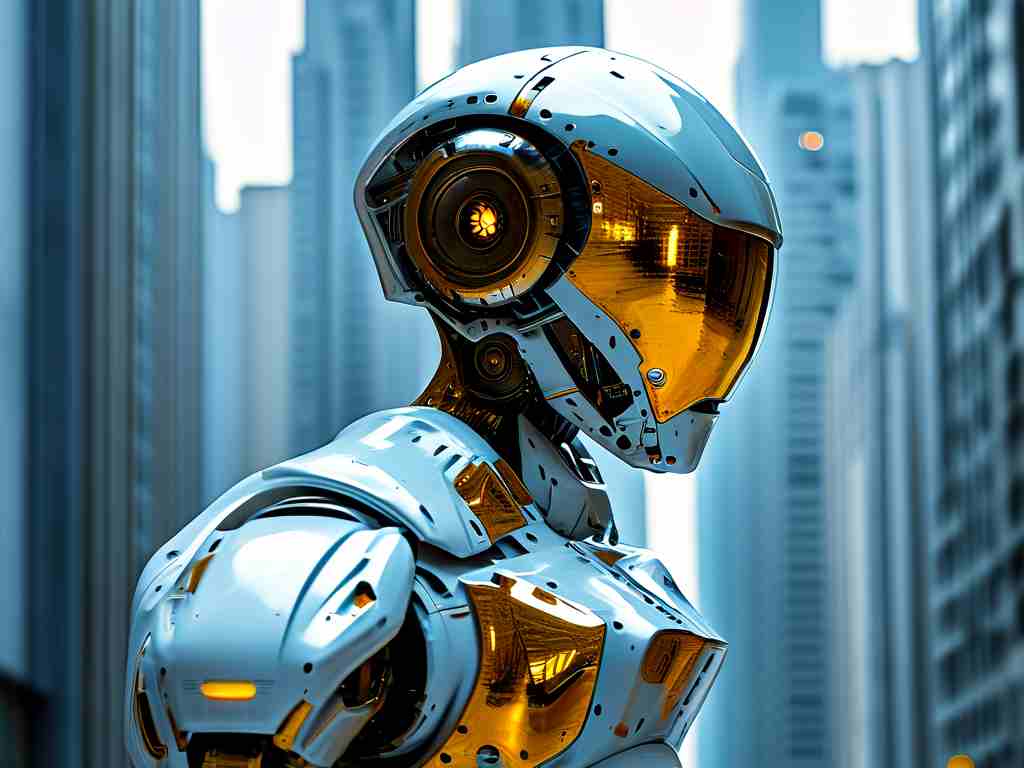

As global industries accelerate digital transformation, Siasun Robotics & Automation Co., Ltd. has emerged as a trailblazer in intelligent manufacturing solutions. Headquartered in Shenyang, China, this technology powerhouse combines cutting-edge robotics with industrial expertise to redefine productivity across multiple sectors.

Core Technological Framework

At the heart of Siasun's success lies its proprietary modular robotics architecture. Unlike conventional systems requiring complete overhauls for upgrades, their "Plug-and-Play" joint modules enable rapid hardware reconfiguration. The ERC-110 collaborative robot series exemplifies this approach, featuring torque sensors with 0.02N·m precision and adaptive grippers supporting 200+ material types. Such flexibility allows seamless integration into existing production lines, reducing deployment time by 40% compared to industry averages.

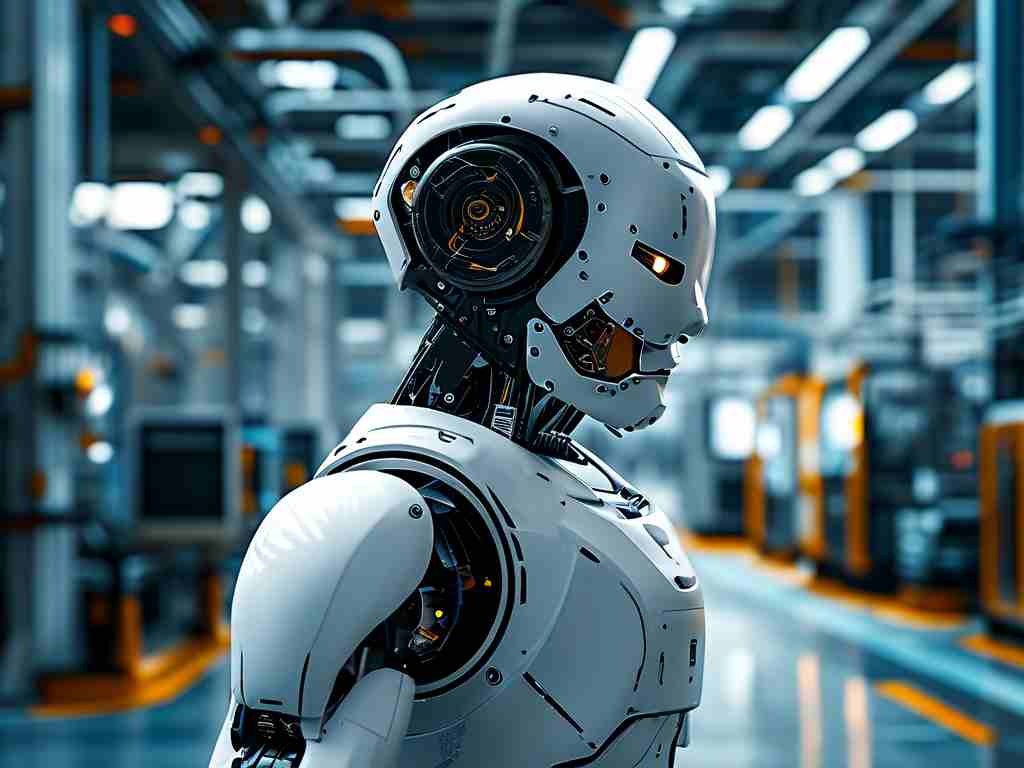

Motion Control Breakthroughs

Siasun's engineers have revolutionized path optimization through hybrid motion planning algorithms. By fusing deep reinforcement learning with traditional kinematics models, their mobile robots achieve 99.6% collision-free navigation in dynamic environments. The latest AGV models incorporate 360° LiDAR mapping and millimeter-wave radar, enabling real-time terrain adaptation – a critical advantage in automotive assembly plants where obstacle patterns change hourly.

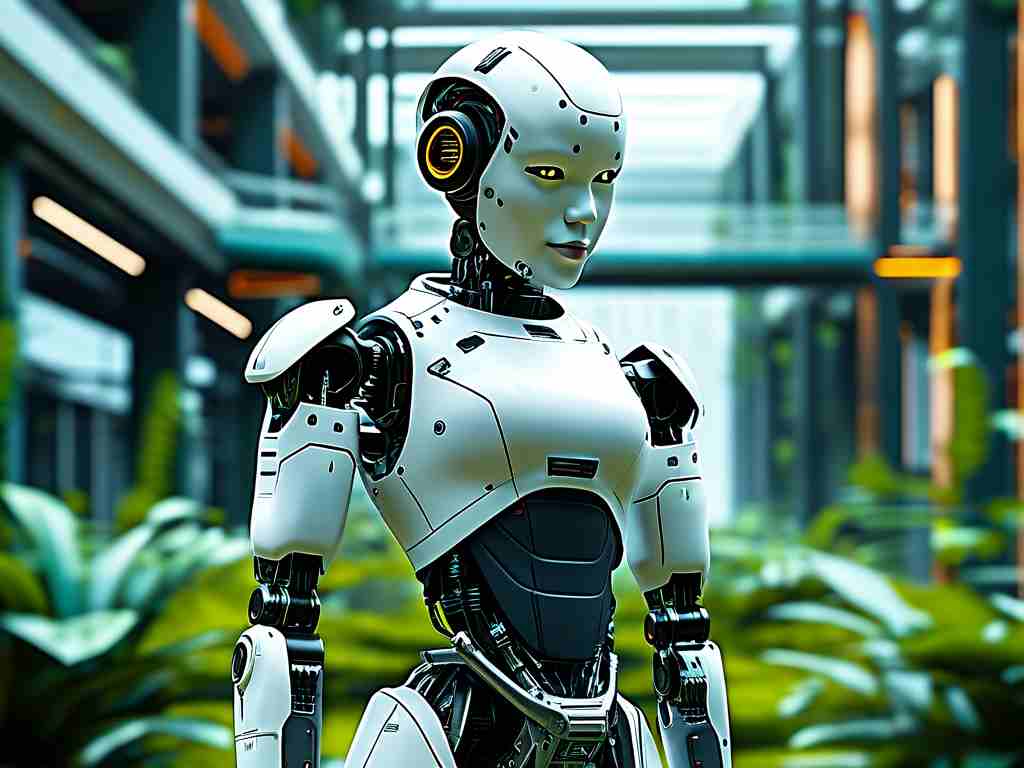

Human-Robot Synergy

The company's Collaborative Operating System (COSys) sets new standards for workplace safety. Using multi-spectral vision sensors and capacitive skin technology, Siasun's robots can detect human presence within 0.3 seconds and adjust torque output accordingly. This innovation has been particularly transformative in pharmaceutical cleanrooms, where robots now handle 80% of sterile packaging tasks while working alongside technicians.

Industry-Specific Solutions

- Semiconductor Manufacturing: Siasun's wafer handling robots operate in Class 1 cleanroom conditions, achieving 0.5μm positioning repeatability. Their vacuum-compatible models have reduced chip contamination rates by 67% in client facilities.

- New Energy Vehicles: The battery module assembly line solution integrates 12-axis robots with machine vision, cutting production cycle times from 28 to 16 minutes per unit.

- Smart Warehousing: Autonomous forklifts equipped with SLAM navigation manage 3,500+ inventory movements daily in 30,000㎡ logistics centers, achieving 99.98% scanning accuracy.

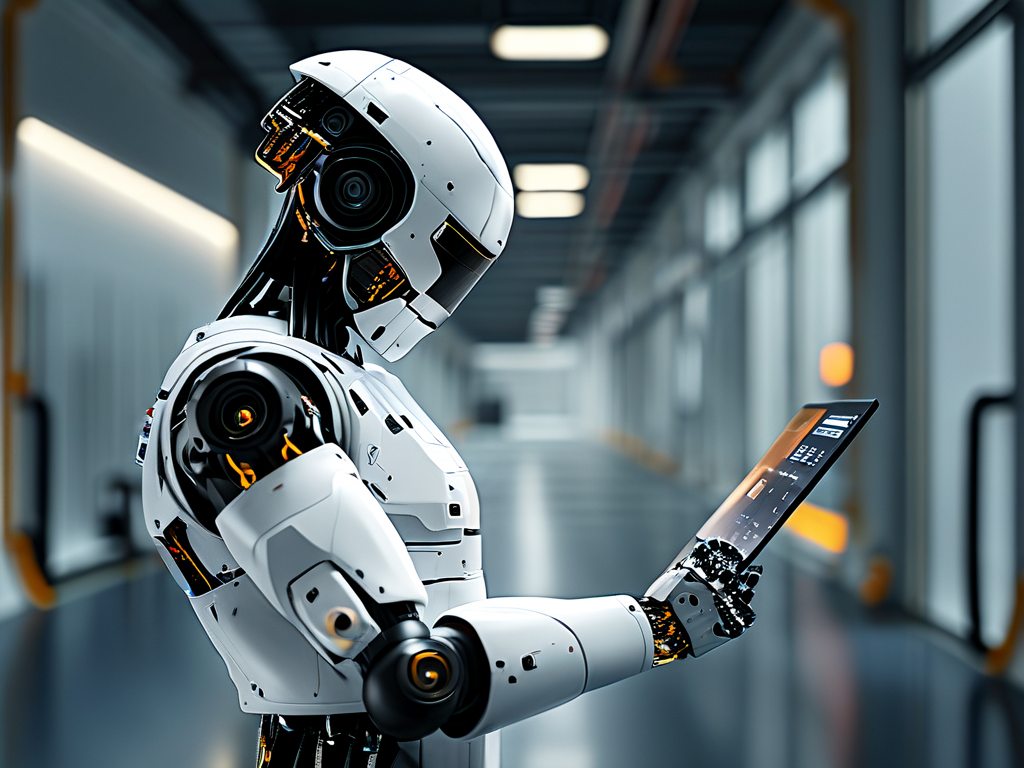

Edge Computing Integration

Recent advancements include embedded AI processors within robot controllers. The NeptuneX computing module processes sensor data locally, reducing cloud dependency by 75%. This edge capability proves vital in offshore oil platform inspections, where robots analyze corrosion patterns in real time despite limited connectivity.

Sustainability Focus

Siasun's energy recovery systems capture kinetic energy during deceleration phases, feeding 18% of expended power back into the grid. Their solar-powered inspection robots, deployed across 12GW of photovoltaic farms, have increased panel maintenance efficiency by 200% while operating carbon-neutral.

Global Impact

With technical centers in Stuttgart and Detroit, Siasun has customized solutions for 56 countries. A notable project in Germany's Ruhr Valley saw 120 Siasun robots modernize a century-old steel plant, reducing energy consumption by 35% while maintaining heritage production techniques.

Future Roadmap

The upcoming Quantum series will incorporate quantum-resistant encryption for industrial IoT security, while biomimetic prototypes with artificial muscle actuators are undergoing field tests. As 6G networks roll out, Siasun plans to leverage sub-millisecond latency for real-time swarm robotics control in large-scale agricultural applications.

From precision micro-assembly to mega-infrastructure projects, Siasun Robotics continues pushing technological boundaries. Their philosophy – "machines that adapt, not dictate" – ensures human expertise remains central to the automation revolution, creating symbiotic ecosystems where innovation serves both productivity and workforce development.