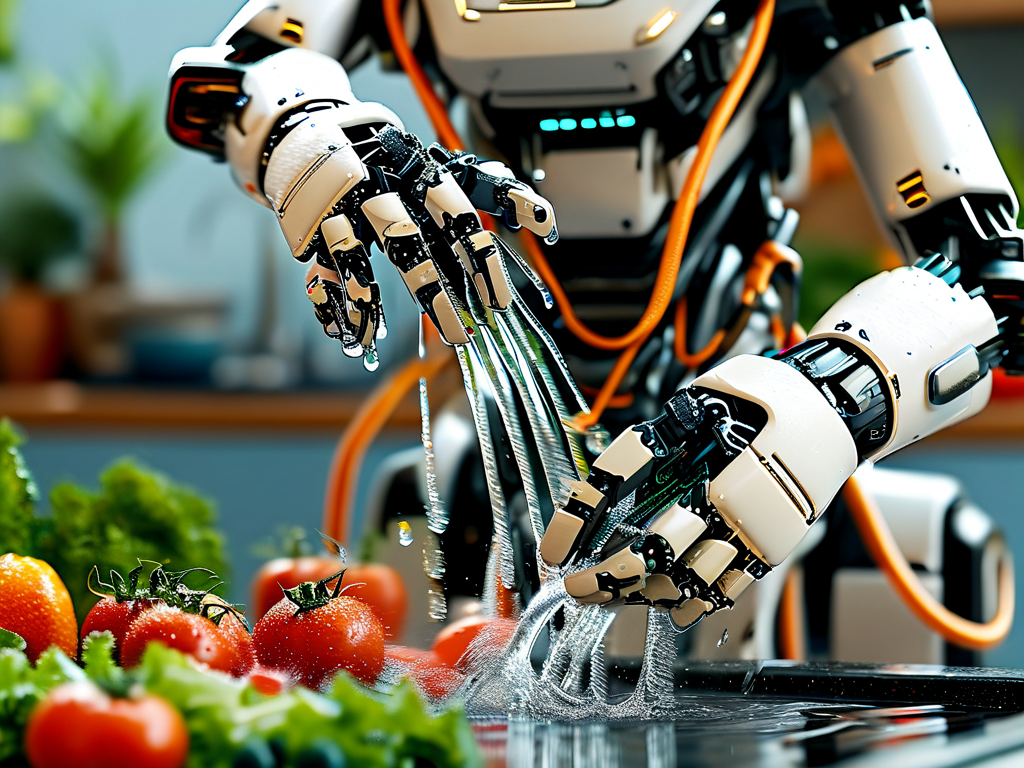

The integration of robotics into culinary workflows has reached a new milestone with the emergence of automated vegetable cleaning systems. These advanced machines combine precision engineering with intelligent algorithms to transform how commercial kitchens and households handle food preparation.

Technical Foundations

Modern vegetable-cleaning robots utilize multi-sensor arrays to analyze produce characteristics in real time. Optical scanners detect surface imperfections while spectrometers identify pesticide residues, enabling customized washing protocols. The latest models feature adaptive water pressure systems that adjust spray patterns based on vegetable type – delicate leafy greens receive gentle misting, while root vegetables endure high-pressure jets to remove stubborn soil.

Operational Advantages

Commercial kitchens report 40% reduction in prep time when using these systems. The XYZ-3000 model, for instance, processes 15kg of mixed vegetables in under 8 minutes while maintaining 98% structural integrity. Energy efficiency has become a key focus, with newer units recycling up to 70% of water through advanced filtration systems.

Safety Enhancements

Automated cleaning eliminates human contact during critical sanitation stages, reducing cross-contamination risks. The integration of UV-C sterilization modules in post-wash cycles has shown 99.9% effectiveness against common pathogens like E.coli and Salmonella in clinical tests conducted by Food Safety International.

Implementation Challenges

Despite promising results, adoption barriers persist. Initial costs remain prohibitive for small-scale operations, with entry-level units priced around $12,000. Technical limitations in handling irregularly shaped produce like artichokes or dragon fruit still require human intervention. Maintenance complexities also pose challenges, as mineral deposits in water systems can reduce sensor accuracy by 18-22% over six months of continuous use.

Future Developments

Industry leaders predict three key advancements within five years:

- AI-powered quality assessment modules that predict vegetable shelf life

- Self-cleaning mechanisms using biodegradable enzymatic solutions

- Compact models for residential use under $3,000

The environmental impact of these systems is drawing increased attention. Preliminary studies indicate that optimized water usage could save 2.7 million liters annually per mid-sized food processing facility.

Practical Applications

From high-end restaurants to school cafeterias, early adopters report measurable benefits. Chef Laurent Dubois of Paris's Michelin-starred Le Céleste notes: "Our staff now focuses on creative tasks rather than repetitive washing. The consistency achieved by machines has elevated our plating standards."

As regulatory bodies develop certification frameworks for automated food handling, this technology appears poised for mainstream adoption. With ongoing refinements in cost efficiency and operational versatility, robotic vegetable cleaning systems are redefining kitchen hygiene standards while addressing critical labor shortages in the food service industry.