The rapid evolution of robotics has ushered in a new era of industrial and societal transformation. Recent advancements in artificial intelligence, sensor technology, and material science have enabled robots to perform tasks with unprecedented precision and adaptability. From manufacturing floors to surgical theaters, these innovations are redefining efficiency and expanding the boundaries of what machines can achieve.

One groundbreaking development is the integration of adaptive machine learning algorithms into robotic systems. Unlike traditional programmed robots, modern models now analyze real-time data to optimize their actions. For instance, assembly-line robots in automotive factories can now detect microscopic defects in components using hyperspectral imaging—a capability that reduces waste by 22% compared to older systems. This shift from rule-based operations to dynamic decision-making marks a pivotal leap in industrial automation.

Another frontier lies in collaborative robotics (cobots). Designed to work alongside humans, cobots employ advanced force-sensing mechanisms to ensure safety. A notable example is the automotive sector’s adoption of UR10e arms, which assist technicians in lifting heavy parts while adjusting their speed based on proximity sensors. Such synergy has boosted production rates by 35% at Volvo’s Gothenburg plant, demonstrating how human-robot partnerships enhance productivity without compromising workplace safety.

The medical field has also witnessed revolutionary applications. Surgical robots like the da Vinci SP platform now execute minimally invasive procedures with sub-millimeter accuracy. Recent trials at Johns Hopkins Hospital revealed that AI-guided robotic systems reduced procedure times for complex spinal surgeries by 28%, while lowering postoperative complications. These advancements not only improve patient outcomes but also alleviate the physical strain on healthcare professionals.

Agriculture, too, is undergoing robotic metamorphosis. Autonomous drones equipped with multispectral cameras monitor crop health across vast farmlands, identifying pest infestations weeks before visible symptoms emerge. Meanwhile, robotic harvesters like Agrobot’s SW6010 use machine vision to selectively pick ripe strawberries at a rate of 8,000 units per hour—eight times faster than human laborers. Such innovations address labor shortages while promoting sustainable farming practices through precision resource allocation.

Despite these strides, challenges persist. Energy efficiency remains a bottleneck for mobile robots, with current battery technologies limiting operational durations. Researchers at MIT’s Computer Science and AI Lab recently unveiled a prototype using phase-change materials to store and release thermal energy, extending drone flight times by 40%. This breakthrough hints at a future where robots operate continuously in remote or hazardous environments, from deep-sea exploration to disaster response.

Ethical considerations also demand attention. As robots assume roles in caregiving and education, questions arise about data privacy and algorithmic bias. The European Union’s proposed Artificial Intelligence Act seeks to establish accountability frameworks, requiring transparency in decision-making processes for robots used in high-risk sectors. Balancing innovation with regulation will be crucial to fostering public trust in these technologies.

Looking ahead, the convergence of 5G connectivity and edge computing promises to amplify robotic capabilities. Real-time data processing at the "edge" of networks enables faster response times for autonomous vehicles and smart factory systems. For example, Siemens’ experimental 5G-enabled factory in Nuremberg achieved a 0.01-second latency in robotic communication, allowing synchronized operations across 120 interconnected machines.

In the consumer sphere, domestic robots are evolving beyond vacuum cleaners. Projects like Toyota’s Human Support Robot (HSR) demonstrate assistive capabilities for elderly care, combining object recognition with gentle manipulators to fetch items or open doors. Meanwhile, Boston Dynamics’ Spot robot has been adapted for construction site inspections, navigating uneven terrain while generating 3D maps for architects.

Educational institutions are also leveraging robotics to prepare future workforces. The University of Tokyo’s “Robot Programming Gym” teaches students to code adaptive behaviors using ROS (Robot Operating System), simulating scenarios from warehouse logistics to emergency rescue operations. Such hands-on training bridges the gap between theoretical AI knowledge and practical implementation.

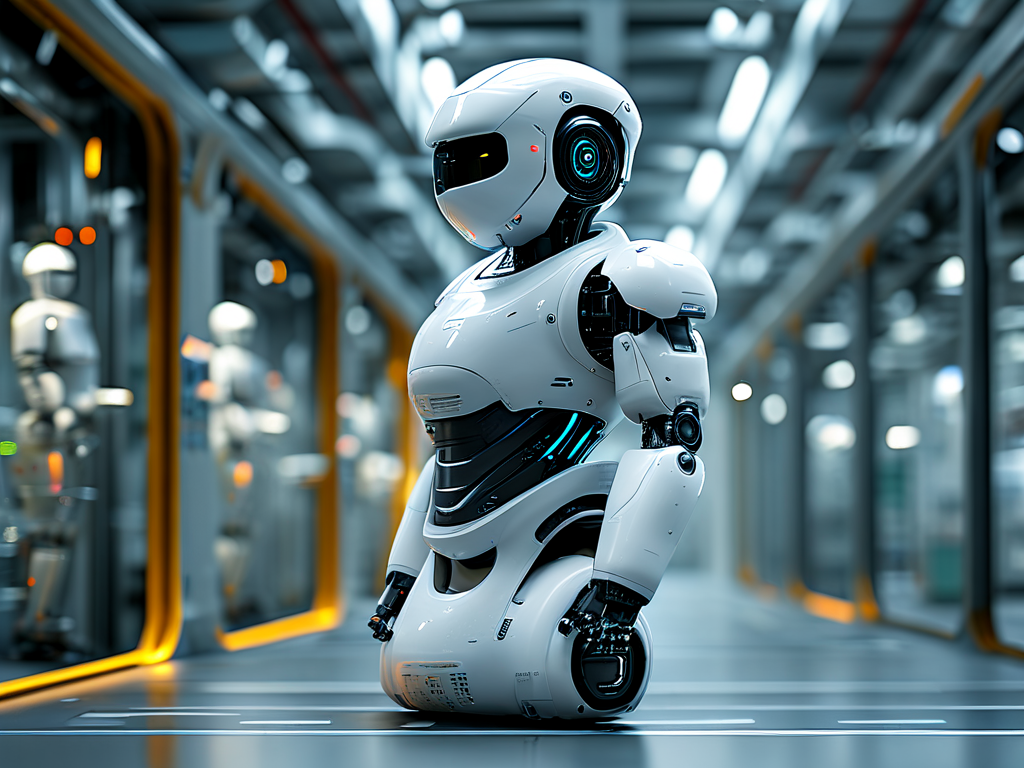

As these technologies mature, cross-industry collaborations are accelerating innovation. Tesla’s Optimus humanoid robot, for instance, shares AI architecture with its autonomous vehicles, demonstrating how automotive advancements can catalyze breakthroughs in general-purpose robotics. Similarly, pharmaceutical giant Pfizer employs robotic labs that combine liquid handling robots with AI-driven compound analysis, slashing drug discovery timelines from years to months.

The economic implications are profound. A 2023 World Economic Forum report estimates that robotics could contribute $4.5 trillion annually to global GDP by 2030 through productivity gains. However, this growth necessitates workforce reskilling initiatives. Companies like Amazon have already invested $700 million in upskilling programs, training employees to supervise robotic systems rather than compete with them.

In , the surge in robotic innovation represents not merely technological progress but a fundamental reimagining of human-machine collaboration. As boundaries between physical and digital realms blur, these advancements promise solutions to pressing global challenges—from climate change to healthcare accessibility. The key lies in steering this transformation responsibly, ensuring that robotics serves as a tool for equitable progress rather than a source of division.