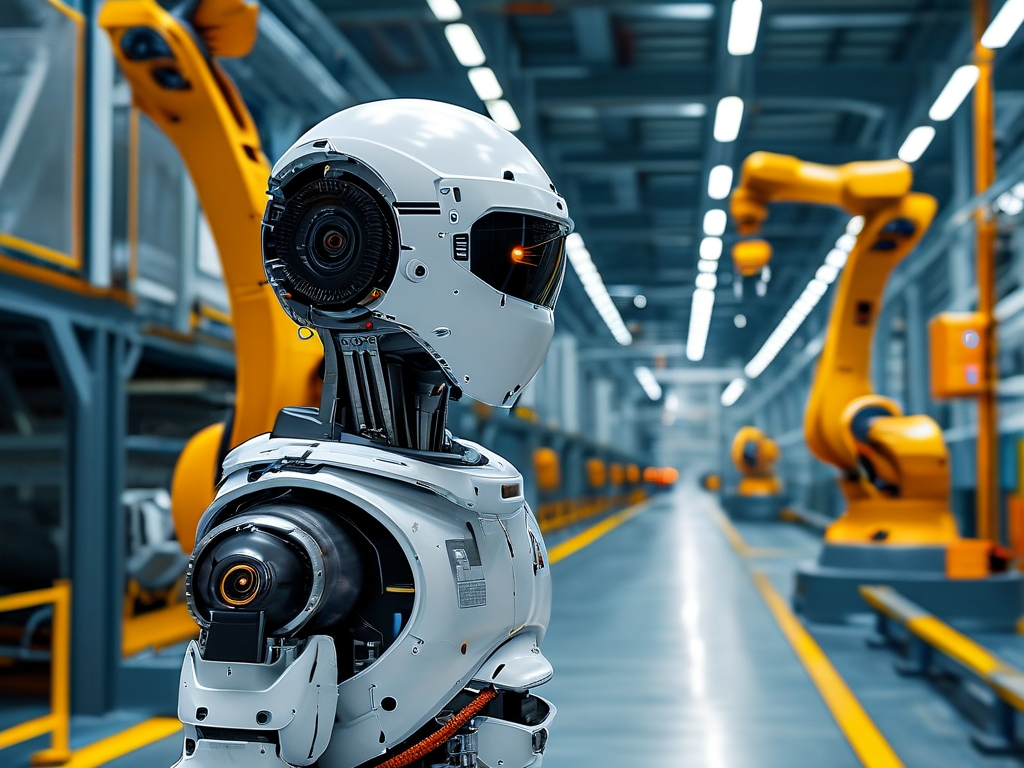

As global industries accelerate digital transformation, Zhejiang Province has emerged as a trailblazer in intelligent inspection robotics, redefining operational efficiency and safety standards. Leveraging its robust manufacturing ecosystem and cutting-edge R&D capabilities, the region is setting benchmarks for autonomous industrial monitoring systems.

Technological Evolution in Zhejiang’s Robotics Sector

Zhejiang’s journey toward intelligent inspection robotics began with its strategic focus on integrating artificial intelligence (AI) and IoT technologies into traditional industries. Companies like Hikvision and Dahua Technology have pioneered robots equipped with multi-sensor fusion, high-precision positioning, and adaptive learning algorithms. These machines excel in environments ranging from power grid substations to chemical plants, where human access is risky or inefficient.

A standout innovation is the development of "all-weather" inspection robots deployed across Hangzhou’s urban infrastructure. These units utilize thermal imaging and LiDAR to detect anomalies in underground pipelines and bridges, reducing maintenance downtime by 40%. Provincial initiatives, such as the "Digital Zhejiang 2025" plan, further fuel advancements by subsidizing R&D collaborations between universities and enterprises.

Applications Reshaping Industries

-

Energy Sector Optimization

State Grid Zhejiang Electric Power Company has integrated autonomous inspection robots into 85% of its high-voltage substations. These robots employ ultrasonic flaw detection and infrared spectroscopy to identify equipment wear 3–6 months before failures occur. In 2023 alone, this system prevented over 200 potential outages, saving an estimated ¥320 million in economic losses. -

Smart Manufacturing Integration

Ningbo’s Sinopec Zhenhai Refinery exemplifies how inspection robots enhance petrochemical safety. Explosion-proof models navigate complex refinery layouts, using gas-sensitive nanosensors to detect leaks at concentrations as low as 1 ppm. Real-time data transmission to centralized control rooms has cut emergency response times by 70%. -

Transportation Infrastructure Monitoring

The Hangzhou Bay Bridge now relies on a fleet of drones and crawling robots for structural assessments. Equipped with 8K-resolution cameras and AI-powered crack analysis software, these devices complete inspections in 12 hours—a task previously requiring 30 workers over three days.

Technical Advantages and Challenges

Zhejiang’s robots stand out for their modular design, allowing customization for sectors like mining or agriculture. For instance, Zhejiang University’s team recently developed a vineyard inspection robot that analyzes soil moisture and grape ripeness using hyperspectral imaging.

However, challenges persist. High initial costs (averaging ¥200,000–¥500,000 per unit) limit SME adoption. Additionally, while 5G-enabled robots achieve 99.98% data accuracy in urban settings, signal latency remains problematic in remote mountainous areas. Cybersecurity is another concern, with Zhejiang’s Cybersecurity Administration reporting a 23% rise in industrial IoT breach attempts in 2023.

Future Directions and Global Impact

Zhejiang aims to reduce robotics costs by 35% through scaled production and open-source software platforms by 2026. Collaborative projects with Germany’s Fraunhofer Institute are exploring hybrid inspection systems combining ground robots and autonomous aerial vehicles (AAVs).

The province’s innovations are gaining international traction. A recent partnership with Singapore’s JTC Corporation will deploy Zhejiang-designed robots at Tuas Industrial Port, marking China’s first large-scale export of intelligent inspection systems.

As Professor Li Qiang from Zhejiang Robotics Association notes, “The next frontier is edge computing integration. Robots that process data locally will overcome cloud dependency, making them viable for offshore wind farms and cross-border pipelines.” With continuous advancements, Zhejiang is not just automating inspections—it’s rewriting the rules of industrial stewardship.