Modern engineering and automation increasingly rely on advanced architectures to enhance efficiency and scalability. Among these, distributed electric control architecture has emerged as a transformative framework, particularly in industries like automotive manufacturing, industrial automation, and smart infrastructure. This article explores its design principles, operational advantages, and real-world applications while addressing common challenges.

Core Design Principles

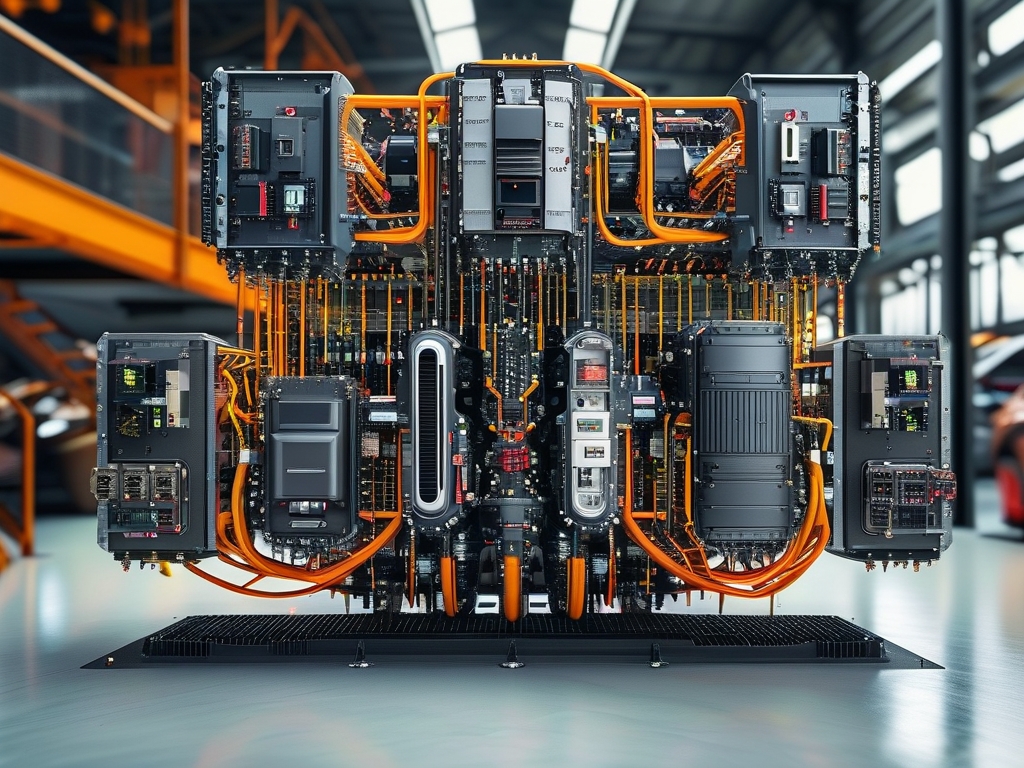

A distributed electric control architecture decentralizes decision-making and processing tasks across multiple interconnected nodes rather than relying on a single central controller. Each node, often referred to as an Electronic Control Unit (ECU), operates semi-independently while communicating with others via high-speed networks such as CAN (Controller Area Network) or Ethernet. This setup minimizes latency, reduces wiring complexity, and improves fault tolerance. For example, in electric vehicles, critical systems like battery management, motor control, and infotainment function as separate ECUs that share data without overburdening a central processor.

Key Advantages

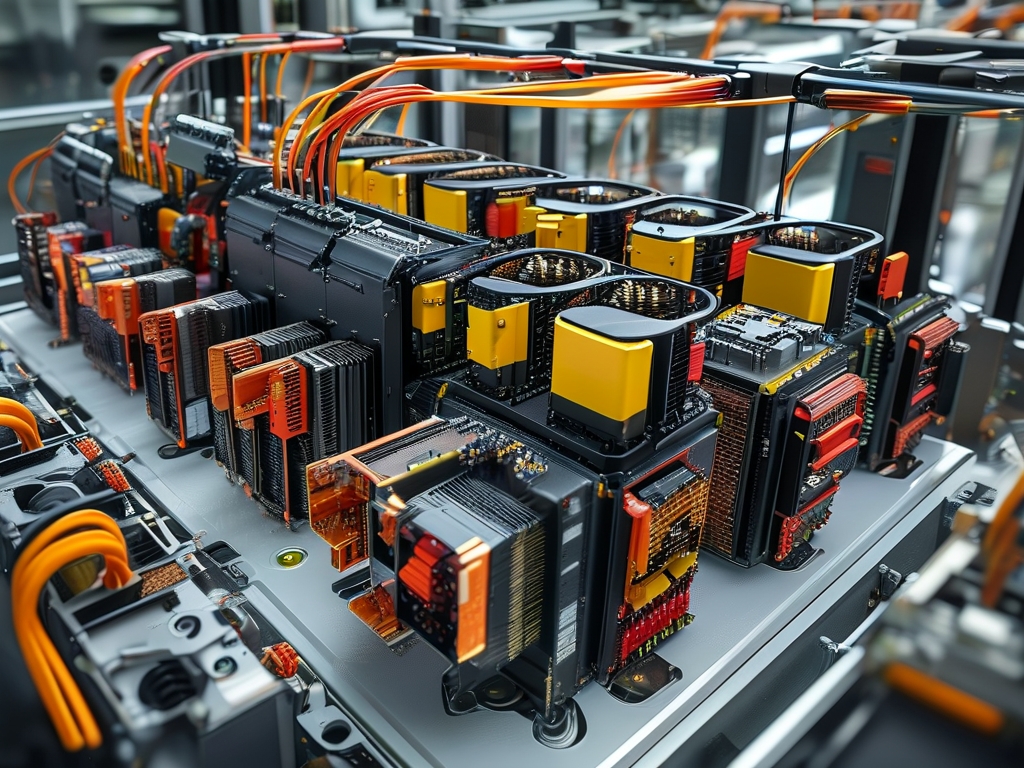

- Modularity and Scalability: Adding or upgrading components becomes simpler since new ECUs can be integrated without redesigning the entire system. Automotive manufacturers, for instance, use this flexibility to introduce advanced driver-assistance features post-production.

- Enhanced Reliability: If one ECU fails, others continue operating, preventing total system shutdown. Industrial robots leverage this feature to maintain productivity even during partial malfunctions.

- Optimized Resource Allocation: Processing tasks are distributed based on node capabilities. In smart grids, sensors and actuators locally manage energy distribution, reducing reliance on centralized servers.

Technical Implementation

A typical distributed system includes three layers:

- Sensing/Actuation Layer: Nodes collect data from sensors (e.g., temperature, pressure) or execute commands (e.g., activating a motor).

- Communication Layer: Protocols like MQTT or OPC UA ensure secure, real-time data exchange between nodes.

- Control Layer: Algorithms running on ECUs process inputs and coordinate actions. For example, Tesla’s Autopilot uses distributed computing to analyze camera feeds and radar data simultaneously across multiple ECUs.

Code snippets for basic ECU communication (simplified):

# CAN bus message transmission example import can bus = can.interface.Bus(channel='can0', bustype='socketcan') msg = can.Message(arbitration_id=0x123, data=[0x1A, 0x2B, 0x3C]) bus.send(msg)

Industry Applications

- Automotive: Electric vehicles (EVs) use distributed architectures to manage battery systems, regenerative braking, and autonomous driving features.

- Manufacturing: Assembly lines deploy ECUs to synchronize robotic arms and conveyor belts.

- Energy Management: Smart grids balance load distribution using decentralized controllers.

Challenges and Solutions

Despite its benefits, this architecture faces hurdles like synchronization delays and cybersecurity risks. Engineers mitigate these by:

- Implementing time-sensitive networking (TSN) to prioritize critical data packets.

- Using encryption protocols like AES-256 to secure node-to-node communication.

- Conducting rigorous simulation testing to identify bottlenecks before deployment.

Future Trends

Advances in edge computing and AI will further decentralize control systems. For instance, AI-driven ECUs could predict equipment failures autonomously, while 5G-enabled networks will enhance real-time coordination in smart cities.

In summary, distributed electric control architecture represents a paradigm shift in system design, balancing flexibility with robustness. As industries embrace automation, its role in enabling scalable, resilient solutions will only grow more pivotal.