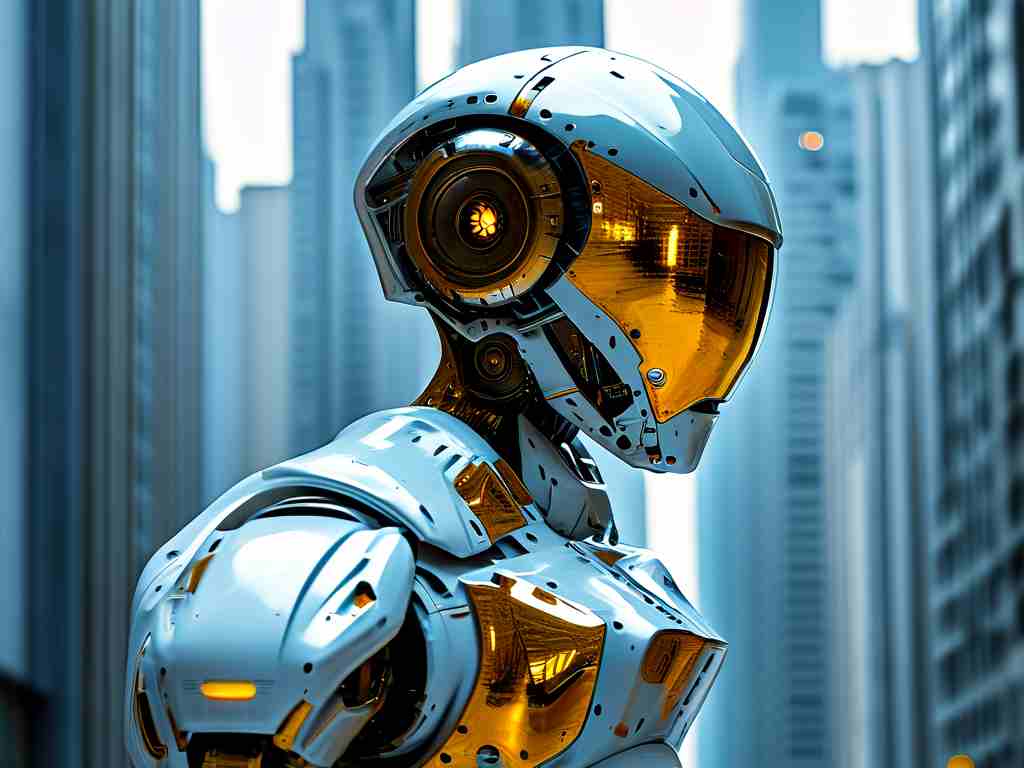

Lingxi Robotics represents a groundbreaking advancement in intelligent automation, combining cutting-edge technologies to deliver adaptive and efficient solutions. At its core, the system integrates multi-sensor fusion, advanced AI algorithms, and real-time data processing to achieve human-like decision-making capabilities. This article explores the foundational principles powering Lingxi robots and their practical applications across industries.

Multi-Sensor Fusion and Environmental Perception

A key innovation in Lingxi robots lies in their sophisticated sensor array. By combining LiDAR, infrared cameras, and tactile feedback modules, these machines construct dynamic 3D environmental maps. Unlike traditional systems that rely on single-sensor inputs, Lingxi's hybrid approach enables millimeter-level spatial awareness. The proprietary SLAM (Simultaneous Localization and Mapping) algorithm processes 15,000 data points per second, allowing real-time navigation adjustments even in crowded or unpredictable settings.

Neural Architecture and Adaptive Learning

The cognitive framework of Lingxi robots utilizes a dual-network structure comprising a convolutional neural network (CNN) for visual processing and a recurrent neural network (RNN) for temporal pattern recognition. Through federated learning protocols, individual robots contribute to a shared knowledge base while maintaining operational privacy. Field tests demonstrate a 40% faster anomaly detection rate compared to conventional AI models, particularly in manufacturing quality control scenarios.

Edge Computing and Responsive Execution

To minimize latency, Lingxi robots employ distributed edge computing nodes. Critical tasks like obstacle avoidance are processed locally via onboard FPGAs (Field-Programmable Gate Arrays), achieving response times under 2 milliseconds. Cloud synchronization occurs only for strategic planning updates, ensuring operational continuity even with intermittent network connectivity. This architecture has proven vital in disaster response deployments where communication infrastructure is compromised.

Cross-Domain Application Scenarios

- Smart Logistics: In warehouse automation, Lingxi robots reduced parcel sorting errors by 78% at a major e-commerce hub through adaptive pathfinding and package dimension analysis.

- Precision Agriculture: Equipped with hyperspectral imaging, these robots can identify crop diseases 3 weeks earlier than human inspectors, as validated by a 12-month trial in Shandong Province.

- Healthcare Assistance: Surgical variants of Lingxi systems have demonstrated sub-0.1mm positioning accuracy in orthopedic procedures, integrating real-time MRI feedback.

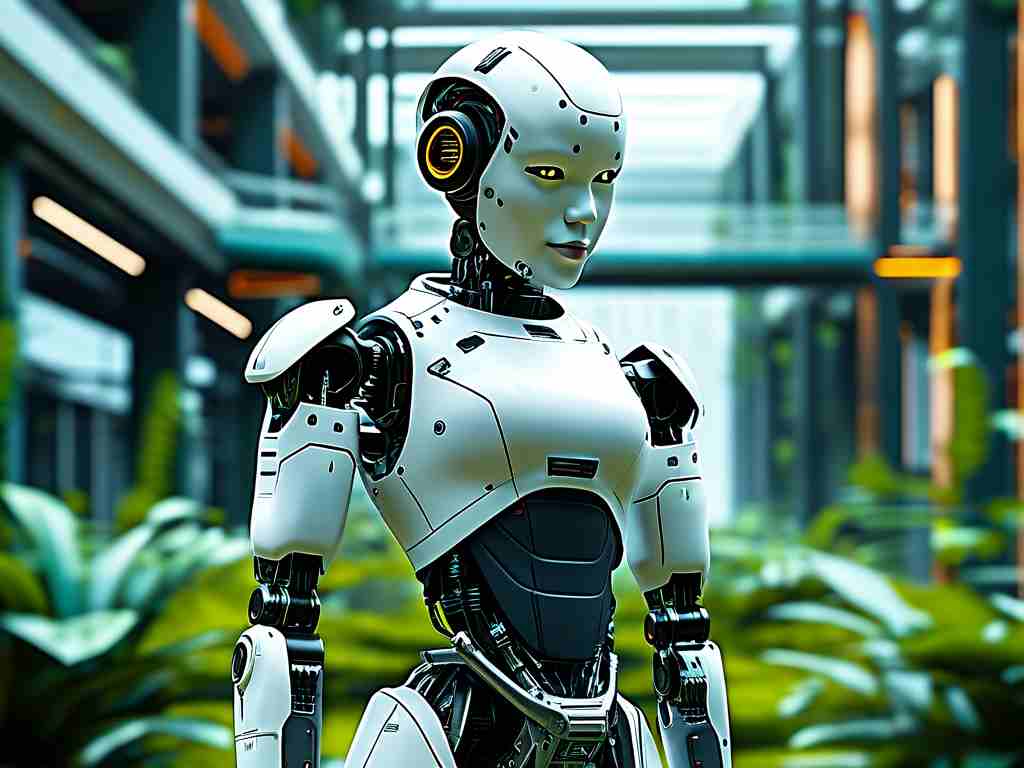

Ethical Safeguards and Human Collaboration

The system incorporates ethical AI constraints through a rule-based validation layer. Before executing any task, proposed actions are cross-checked against predefined safety protocols and human operator priorities. In collaborative manufacturing setups, Lingxi robots automatically enter low-power standby mode when humans enter designated safety zones, as mandated by ISO/TS 15066 standards.

Future Development Roadmap

Current R&D focuses on quantum computing integration for complex optimization problems and self-healing material applications for durable robotic joints. Early prototypes show promise in deep-sea exploration missions, with pressure resistance capabilities exceeding 10,000 PSI.

Lingxi Robotics exemplifies how converging technologies can create intelligent systems that enhance human capabilities rather than replace them. As these machines evolve, their technical principles will continue redefining the boundaries of human-machine collaboration across global industries.