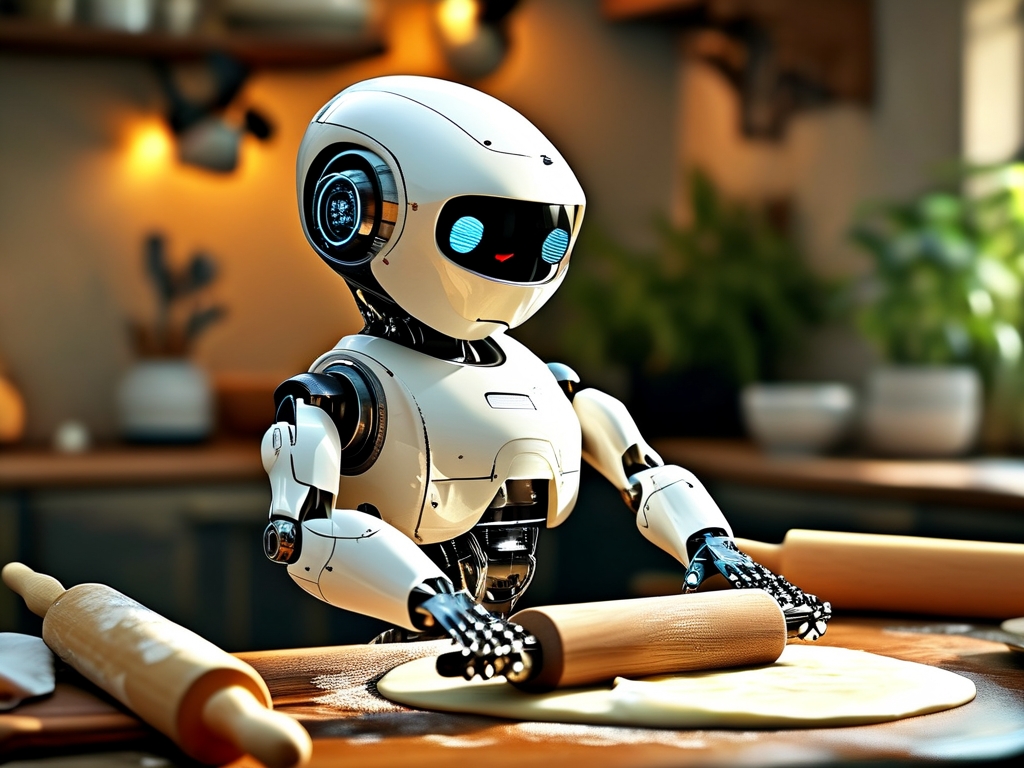

The integration of robotics into culinary processes has revolutionized traditional food preparation methods, and robotic noodle dough rolling stands as a prime example. This technology combines precision engineering, material science, and artificial intelligence to replicate and optimize the age-old practice of dough kneading and rolling. In this article, we delve into the technical principles behind robotic noodle dough rolling systems, their components, and their transformative impact on the food industry.

1. Core Components of Robotic Dough Rolling Systems

A robotic dough rolling system comprises three primary subsystems:

- Mechanical Design: Multi-jointed robotic arms equipped with specialized rollers mimic human wrist movements. These arms apply controlled pressure to flatten dough uniformly. The rollers are often made of food-grade stainless steel or composite materials to prevent sticking and ensure hygiene.

- Sensory Feedback System: Force sensors embedded in the rollers measure dough resistance in real time, while vision systems (e.g., 3D cameras or laser scanners) monitor dough thickness and surface texture. This data is critical for adjusting rolling parameters dynamically.

- Control Algorithms: Machine learning models process sensory data to optimize rolling speed, pressure, and folding patterns. For instance, convolutional neural networks (CNNs) analyze dough elasticity to prevent over-stretching or tearing.

2. The Physics of Dough Manipulation

Dough rheology—the study of its deformation under stress—dictates the engineering requirements. Robotic systems must account for variables such as:

- Viscosity and Elasticity: High-gluten dough requires slower rolling cycles to avoid structural damage.

- Temperature Sensitivity: Infrared sensors track dough temperature, as warmth from friction or ambient conditions affects consistency.

- Layered Folding: For laminated dough (e.g., used in ramen or dumplings), robots perform precise folding motions to create air pockets without compromising integrity.

3. Workflow of a Robotic Rolling Process

A typical automated workflow involves four stages:

- Dough Feeding: Pre-measured dough balls are placed on a conveyor belt using vacuum grippers.

- Initial Compression: A pneumatic press flattens the dough into a base shape.

- Iterative Rolling: The robotic arm applies progressive pressure across multiple passes, mimicking the "resting" phases in manual rolling to relax gluten networks.

- Quality Assurance: Post-rolling, the dough sheet undergoes automated inspection for thickness (±0.1 mm tolerance) and defects.

4. Advantages Over Traditional Methods

- Consistency: Robots eliminate human variability, ensuring uniform thickness—critical for industrial-scale noodle production.

- Efficiency: A single robotic unit can process 200+ dough sheets per hour, surpassing manual labor by 300%.

- Hygiene: Closed systems minimize human contact, reducing contamination risks.

5. Challenges and Innovations

Despite advancements, challenges persist:

- Material Variability: Flour hydration levels and protein content vary by batch, requiring adaptive algorithms.

- Energy Consumption: High-torque motors demand optimized power management. Recent innovations include hybrid hydraulic-electric actuators to reduce energy use by 25%.

- Cultural Acceptance: Some artisanal chefs argue that machines lack the "intuition" of seasoned dough masters. However, AI-driven systems now incorporate historical recipe databases to emulate regional techniques.

6. Case Study: Industrial Adoption

In 2023, Japanese manufacturer Yamato Robotics deployed its NoodleMaster 5.0 system in a ramen factory. The robots reduced waste by 18% and increased output by 40%, demonstrating ROI within eight months. Similar systems are now used in Chinese dumpling chains and Italian pasta facilities.

7. Future Directions

Emerging trends include:

- AI-Powered Customization: Systems that adjust rolling techniques based on customer preferences (e.g., thicker udon or thinner wonton wrappers).

- Collaborative Robots (Cobots): Lightweight cobots working alongside chefs in hybrid kitchens.

- Sustainability Integration: Using dough scraps detected by vision systems to recycle into new batches.

Robotic noodle dough rolling technology exemplifies the synergy between culinary tradition and cutting-edge engineering. By addressing technical challenges and embracing adaptive learning, these systems are poised to redefine global food production standards while preserving the artistry of noodle-making. As the technology matures, its applications will expand beyond noodles to other dough-based delicacies, bridging the gap between automation and gastronomic excellence.